Heteroatom doped starch carbon and preparation method thereof

A heteroatom and starch technology, which is applied in the field of heteroatom-doped starch carbon and its preparation, can solve the problems of less doping amount, lower production cost, and low yield, and achieve simple operation, lower production cost, and simple preparation method easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

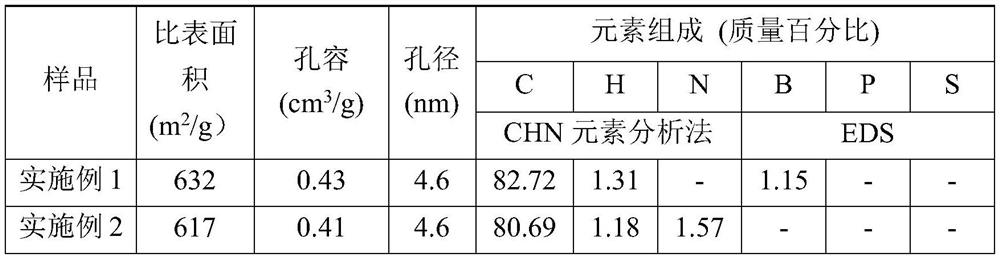

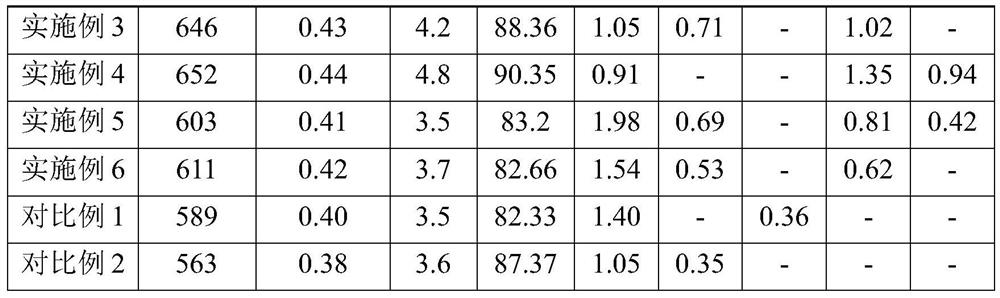

Embodiment 1

[0032] Dry the potato starch in an oven at 100°C for 3 hours, dissolve 1g of boric acid in 50ml of deionized water and stir evenly, take 10g of dried potato starch and add it to the above solution, then add 0.1g of sodium hydroxide with a mass fraction of 10% The solution was stirred in a water bath at 80°C for 2 hours at a speed of 100 rpm. After the reaction was complete, a certain amount of dilute hydrochloric acid with a mass fraction of 5% was added to adjust the pH value of the solution to 7.0. After the starch was filtered, it was placed in an oven and dried at 110°C for 2 hours. Mix the prepared modified starch with 10 mL of aqueous solution containing 1 g of acetic acid, let stand at 20 °C for 8 h, dry in an oven at 150 °C for 10 h, and carbonize in a tube furnace at 800 °C for 2 h under a nitrogen atmosphere with a nitrogen flow rate of 30 mL / min , take out the sample to obtain boron-doped starch charcoal.

Embodiment 2

[0034] Dry the potato starch in an oven at 90°C for 12 hours, dissolve 1g of 3-chloro-2-hydroxypropyltrimethylammonium chloride in 20ml of deionized water and stir evenly, take 10g of dried potato starch and add it to the above solution , then add 0.05g of a mass fraction of 10% sodium hydroxide solution, stir in a water bath at 100° C. for 5 hours, and rotate at 200 rpm. After the reaction is complete, add a certain amount of dilute acetic acid with a mass fraction of 3% to adjust the pH value of the solution to 7.0. After the starch is filtered, it is placed in an oven and dried at 120°C for 10 hours. The prepared modified starch was uniformly mixed with 20 mL of an aqueous solution containing 2 g of p-toluenesulfonic acid, allowed to stand at 20°C for 8 hours, dried in an oven at 150°C for 10 hours, and carbonized in a tube furnace at 600°C for 2 hours under a nitrogen atmosphere. The nitrogen flow rate was 30mL / min, take out the sample to obtain nitrogen-doped starch charc...

Embodiment 3

[0036] Put the cornstarch in an oven at 120°C and dry for 24 hours, take 2g of concentrated phosphoric acid and 0.5g of urea and dissolve it in 60ml of deionized water and stir evenly, take 10g of dried cornstarch and add it to the above solution, adding 0.2g with a mass fraction of 10% The sodium hydroxide solution was stirred in a water bath at 100°C for 6 hours, and the rotation speed was 60 rpm. After the reaction was complete, a certain amount of dilute hydrochloric acid with a mass fraction of 1% was added to adjust the pH value of the solution to 6.5, and the starch was filtered and placed in an oven at 120°C. Dry for 12h. The prepared modified starch was uniformly mixed with 5 mL of ethanol solution containing 1 g of tartaric acid, allowed to stand at 20 °C for 8 h, dried in an oven at 150 °C for 10 h, and carbonized in a tube furnace at 900 °C for 2 h under a nitrogen atmosphere with a nitrogen flow rate of 30 mL / min, the sample was taken out to obtain nitrogen-phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com