Preparation method of amphoteric starch size

A technology of amphoteric starch and sizing, which is applied in the field of preparation of amphoteric starch sizing, which can solve the problems of desizing and other problems, and achieve the effects of easy desizing, high sizing viscosity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

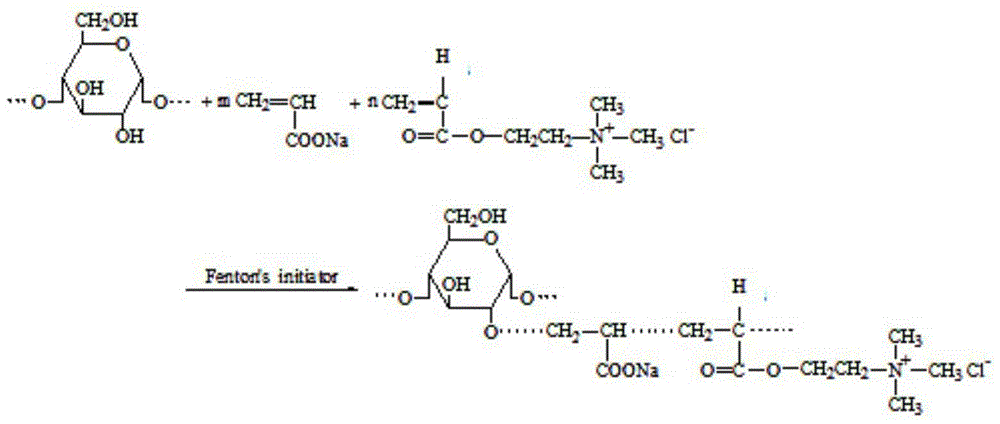

Method used

Image

Examples

Embodiment 1

[0027] The preparation mass fraction is the acid-thinned starch (ATS) aqueous solution of 30%, the pH value of adjusting described acid-thinned starch (ATS) aqueous solution is 3.2, after heating, stirring treatment, pass into nitrogen 45min, dropwise add 12g sodium acrylate, add 18mL mass fraction 0.8% FeSO 4 ·(NH 4 ) 2 SO 4 and 15 mL mass fraction of 1.2% H 2 o 2 solution, and then reacted for 1 h under the protection of nitrogen. Then, add 3 mL of hydroquinone solution with a mass fraction of 2%, and use 1.5 mol / L NaCO 3 The solution adjusts the pH value of the reactant to 5, and then filters, vacuum-dries, pulverizes, and sieves to obtain the product. By calculation, the adhesive force of the product is 123.6N, and the desizing rate is 94.2%.

Embodiment 2

[0029] Preparation mass fraction is 30% acid-thinned starch (ATS) aqueous solution, the pH value of regulating described acid-thinned starch (ATS) aqueous solution is 3.2, through heating, stirring process, feed nitrogen 45min, drip 12g grafting monomer , the mol ratio of acryloyloxyethyltrimethylammonium chloride (DAC) to sodium acrylate in the graft monomer is 0.5:1, adding 18mL mass fraction is 0.8% FeSO 4 ·(NH 4 ) 2 SO 4 and 15 mL mass fraction of 1.2% H 2 o 2 solution, and then reacted for 1 h under the protection of nitrogen. Then, add 3 mL of hydroquinone solution with a mass fraction of 2%, and use 1.5 mol / L NaCO 3 The solution adjusts the pH value of the reactant to 5, and then filters, vacuum-dries, pulverizes, and sieves to obtain the product. By calculation, the adhesive force of the product is 125.4N, and the desizing rate is 92.2%.

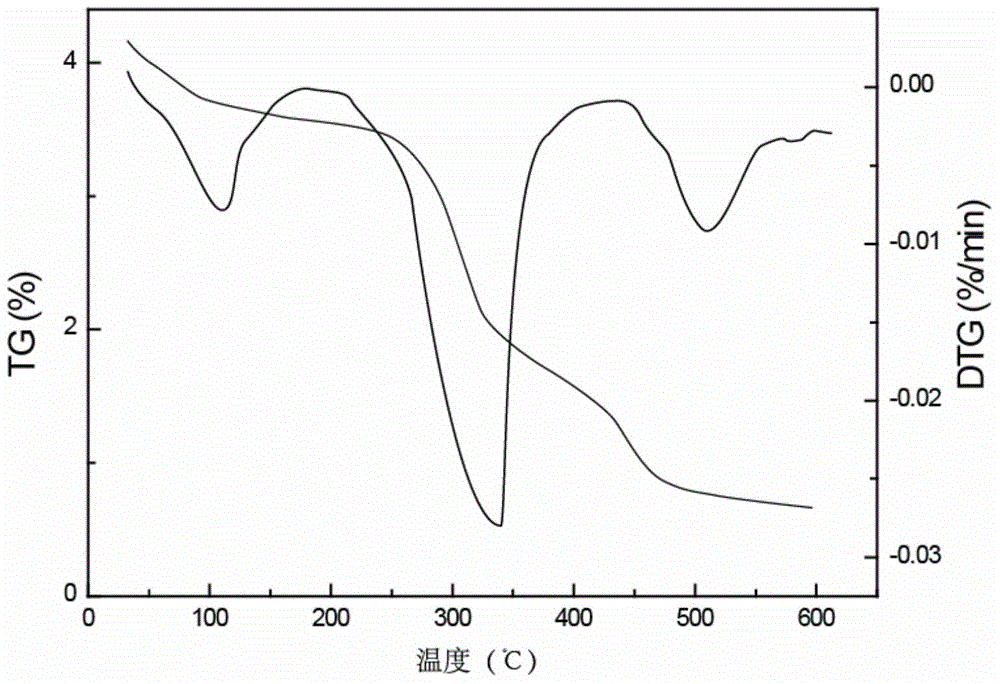

[0030] like figure 1 As mentioned above, the weight loss of the product is mainly divided into three stages. The first stag...

Embodiment 3

[0032] Preparation mass fraction is 30% acid-thinned starch (ATS) aqueous solution, the pH value of regulating described acid-thinned starch (ATS) aqueous solution is 3.2, through heating, stirring process, feed nitrogen 45min, drip 12g grafting monomer , the mol ratio of acryloyloxyethyltrimethylammonium chloride (DAC) to sodium acrylate in the graft monomer is 0.8:1, adding 18mL mass fraction is 0.8% FeSO 4 ·(NH 4 ) 2 SO 4 and 15 mL mass fraction of 1.2% H 2 o 2 solution, and then reacted for 1 h under the protection of nitrogen. Then, add 3 mL of hydroquinone solution with a mass fraction of 2%, and use 1.5 mol / L NaCO 3 The solution adjusts the pH value of the reactant to 5, and then filters, vacuum-dries, pulverizes, and sieves to obtain the product. By calculation, the adhesive force of the product is 127.7N, and the desizing rate is 91.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com