Treatment method for realizing zero emission of printing and dyeing wastewater

A treatment method and technology for printing and dyeing wastewater, which are applied in the textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Large and other problems, to achieve the effect of reducing COD value, no secondary pollution, and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

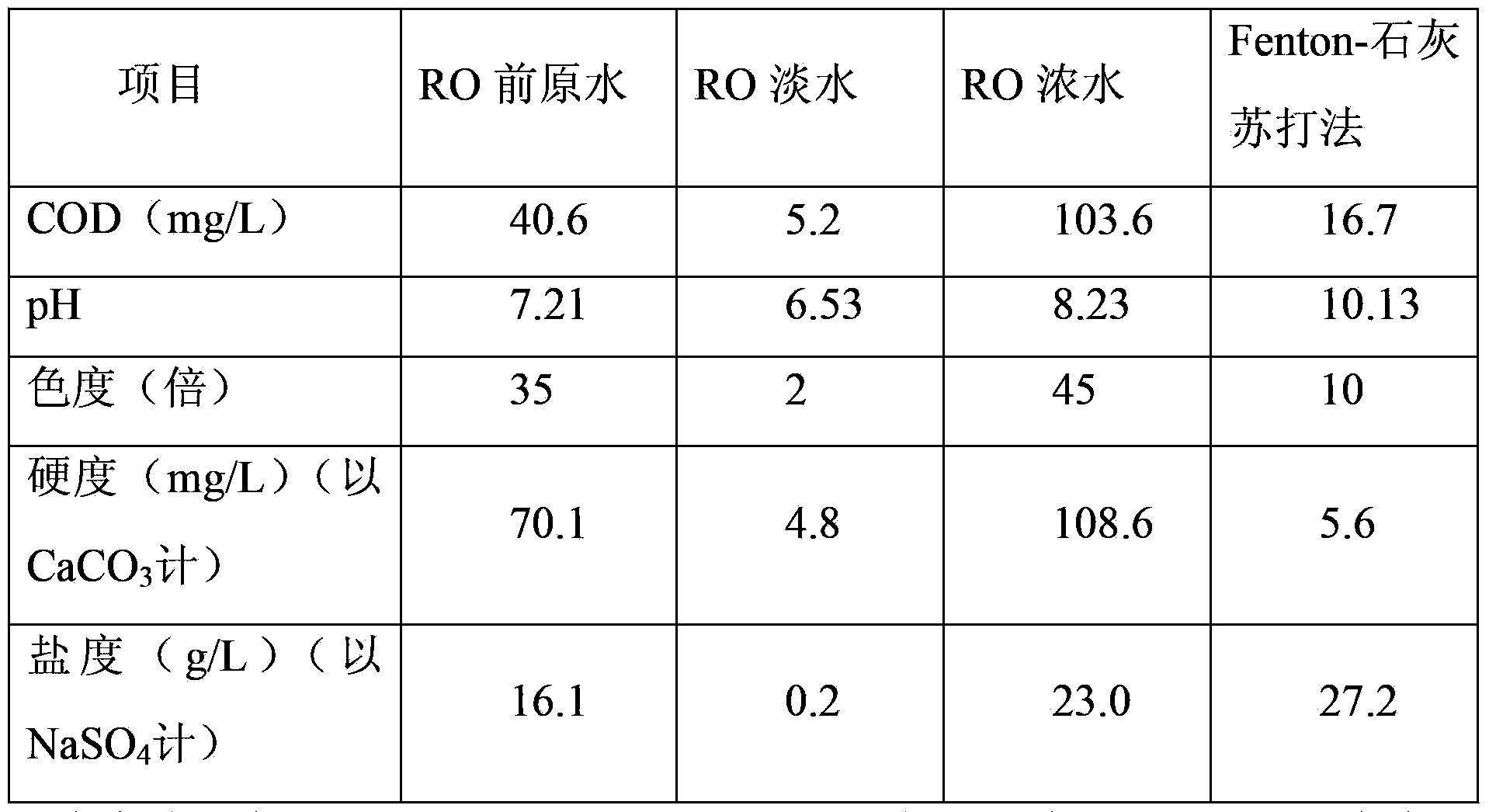

Embodiment 1

[0032] The printing and dyeing wastewater of a printing and dyeing factory is treated as follows:

[0033] (1) Conventional treatment: Physicochemical, anaerobic and aerobic treatment of printing and dyeing wastewater stock solution;

[0034] (2) Advanced treatment: the conventionally treated effluent is subjected to ozone-aerated biological filter, sand filter, ultrafiltration and security filter;

[0035] (3) Membrane treatment: Reverse osmosis treatment is performed on the effluent after advanced treatment to obtain fresh water and concentrated water; the fresh water is directly reused for pigment dissolution, boiler supplementary water, general washing or circulating cooling water, and the concentrated water enters the next treatment process;

[0036] (4) Concentrated water treatment: Take the concentrated water and add it to the oxidation tank, then use hydrogen peroxide as the oxidant and ferrous sulfate as the catalyst to perform Fenton oxidation treatment on the concen...

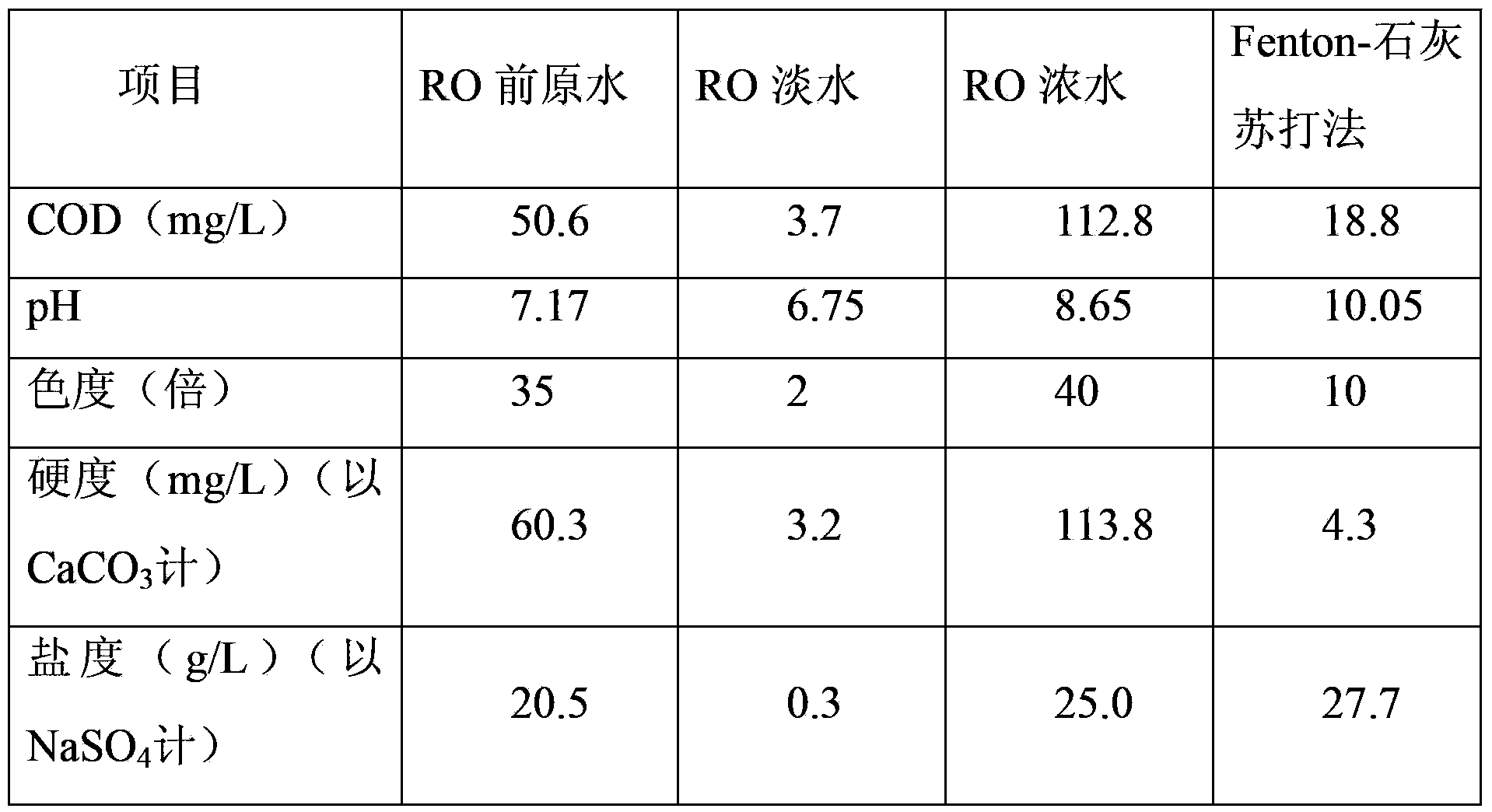

Embodiment 2

[0049] The printing and dyeing wastewater of a printing and dyeing factory is treated as follows:

[0050] (1) Conventional treatment: Physicochemical, anaerobic and aerobic treatment of printing and dyeing wastewater stock solution;

[0051] (2) Advanced treatment: the conventionally treated effluent is subjected to ozone-aerated biological filter, sand filter, and security filter;

[0052] (3) Membrane treatment: Reverse osmosis treatment is performed on the effluent after advanced treatment to obtain fresh water and concentrated water; the fresh water is directly reused for pigment dissolution, boiler supplementary water, general washing or circulating cooling water, and the concentrated water enters the next treatment process;

[0053] (4) Concentrated water treatment: Take the concentrated water and add it to the oxidation tank, then use hydrogen peroxide as the oxidant and ferrous sulfate as the catalyst to perform Fenton oxidation treatment on the concentrated water, an...

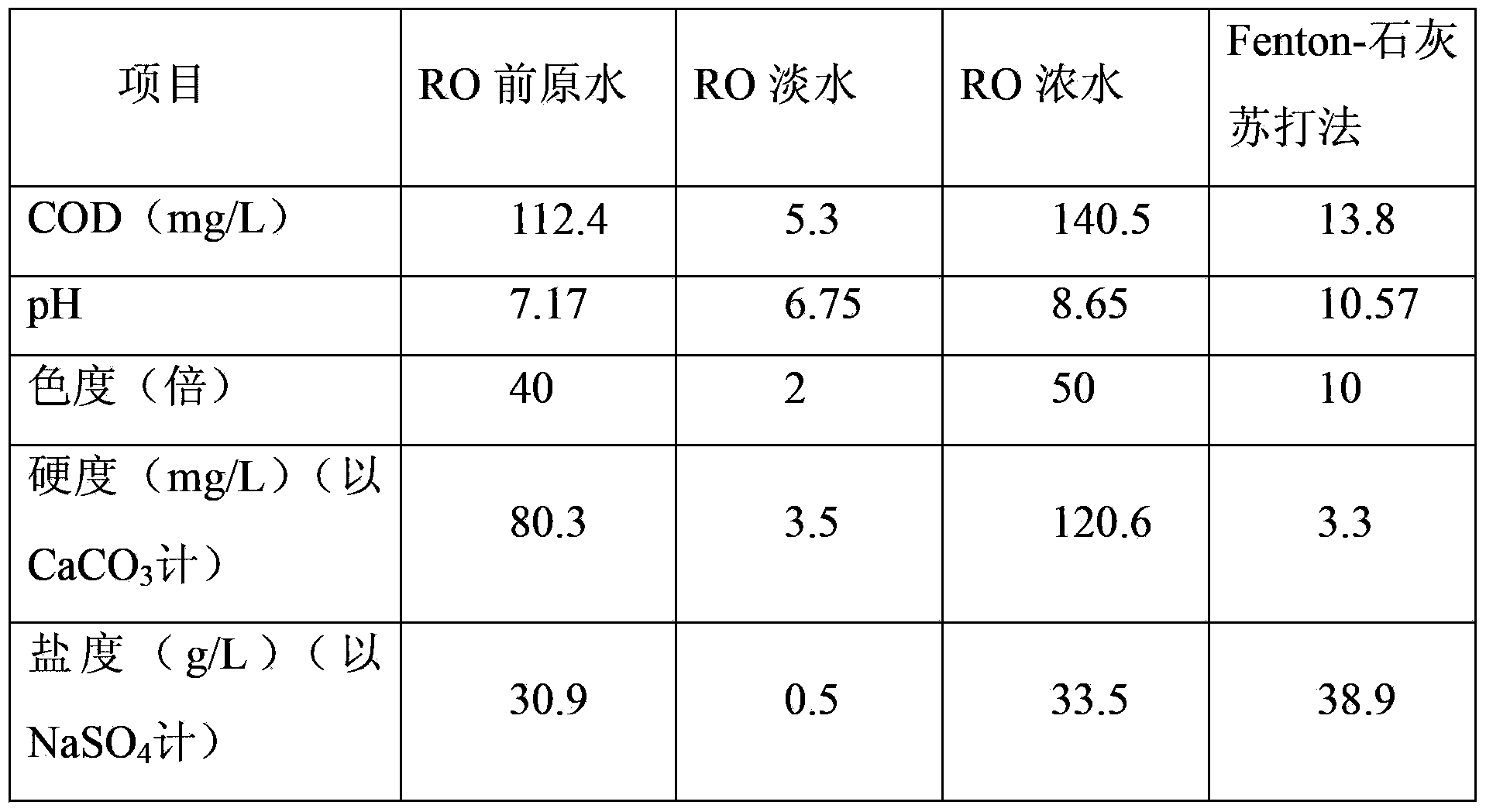

Embodiment 3

[0066] The printing and dyeing wastewater of a printing and dyeing factory is treated as follows:

[0067] (1) Conventional treatment: Physicochemical, anaerobic and aerobic treatment of printing and dyeing wastewater stock solution;

[0068] (2) Advanced treatment: Chlorine disinfection, sand filtration and security filtration are carried out on the conventionally treated effluent;

[0069] (3) Membrane treatment: Reverse osmosis treatment is performed on the effluent after advanced treatment to obtain fresh water and concentrated water; the fresh water is directly reused for pigment dissolution, boiler supplementary water, general washing or circulating cooling water, and the concentrated water enters the next treatment process;

[0070] (4) Concentrated water treatment: Take the concentrated water and add it to the oxidation tank, then use hydrogen peroxide as the oxidant and ferrous sulfate as the catalyst to perform Fenton oxidation treatment on the concentrated water, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com