Reuse treatment method for industrial wastewater from refrigerator compressor factory

A technology for refrigerator compressors and industrial waste water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of reducing turbidity and remarkable removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below by way of examples.

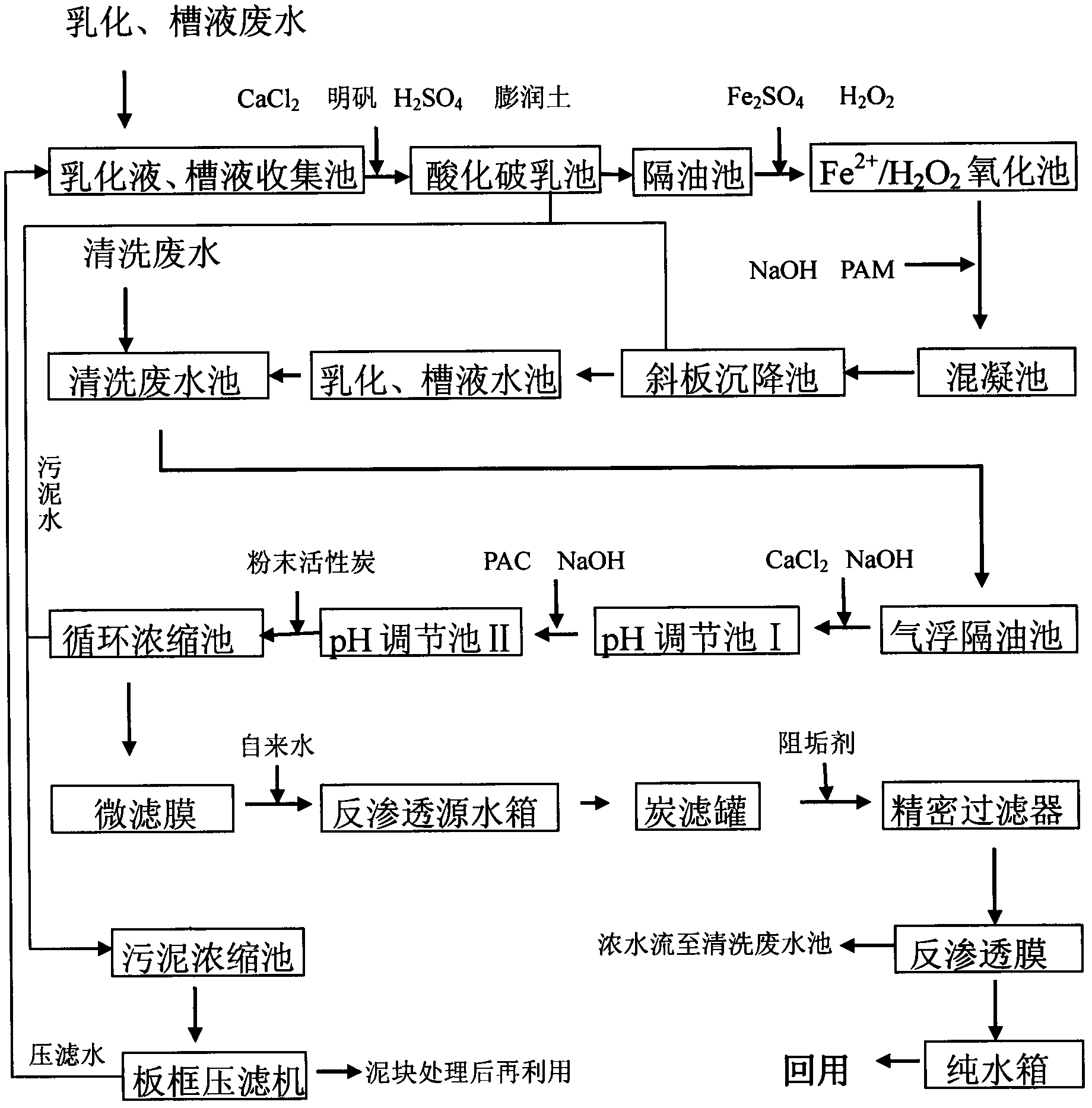

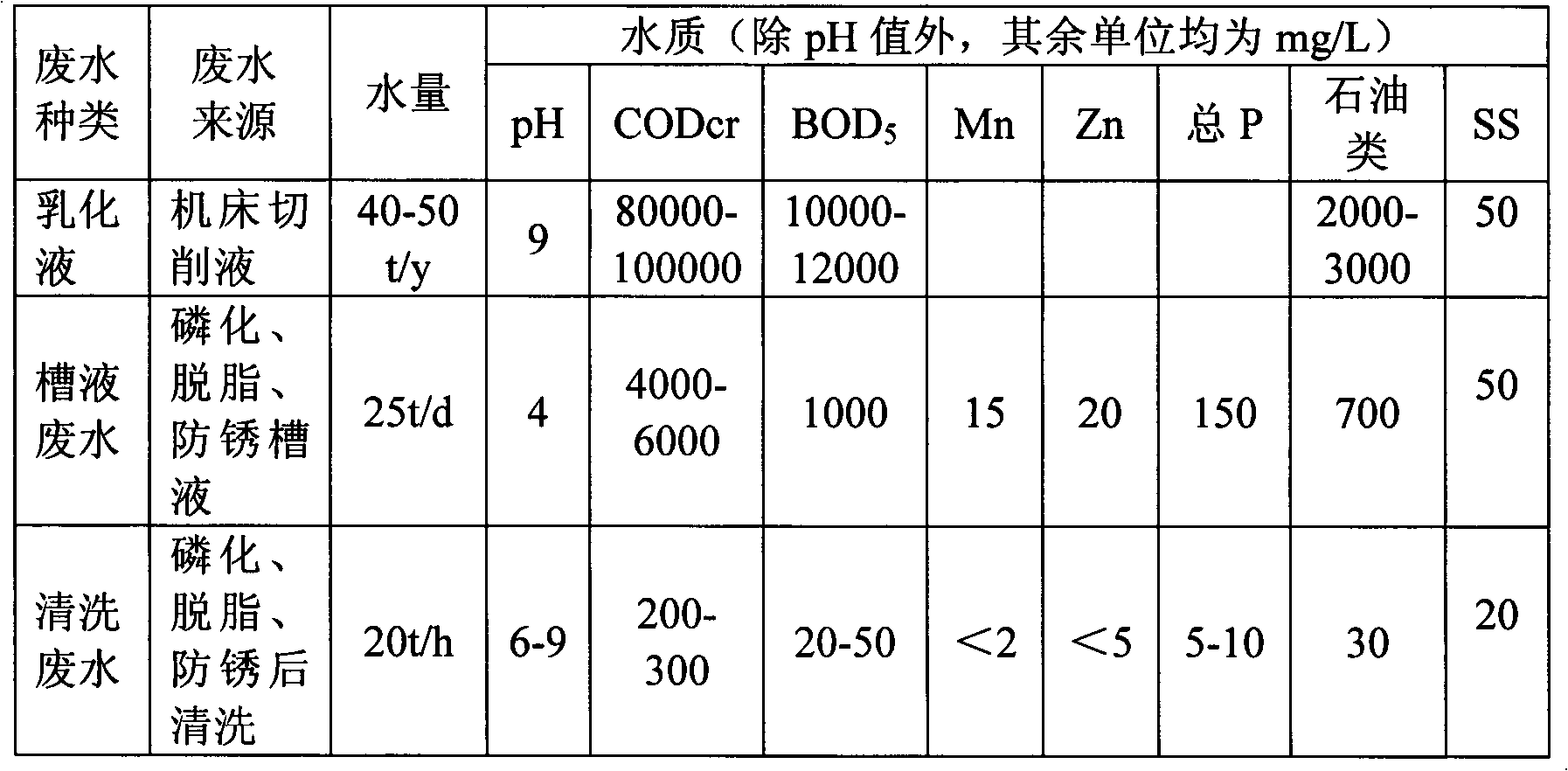

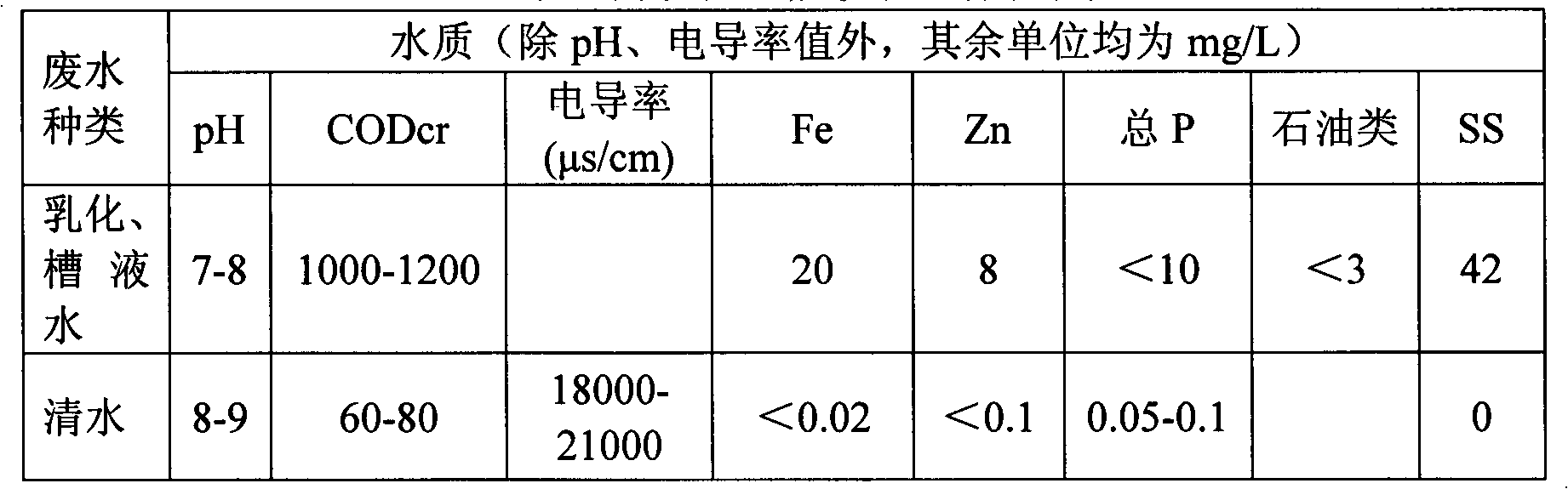

[0031] Taking the waste water reuse treatment of a refrigerator compressor manufacturer in Jiaxing as an example, the process flow is as follows figure 1 shown. Wastewater generated during the manufacturing process of refrigerator compressors is collected through two collection pools: tank liquid, emulsion collection pool and cleaning waste water pool, and is collected in two categories: the emulsion and phosphorus used for machine tool cutting with small water volume, high concentration and complex composition are collected respectively. The bath wastewater produced in chemical, degreasing and anti-rust processing workshops, referred to as emulsification and bath wastewater, is collected in the bath and emulsion collection pools; the other is produced by steel pickling, surface cleaning, and cleaning after phosphating and degreasing. Wastewater with large water volume, low concentration and simple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com