Integration process of coke dry quenching co-production synthesis gas and downstream products thereof of methanol

A CDQ and synthesis gas technology, applied in the chemical industry, coke oven, organic chemistry, etc., can solve the problems of high hydrogen-to-carbon ratio, large investment in reformer, and complex process of producing synthesis gas from coke oven gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

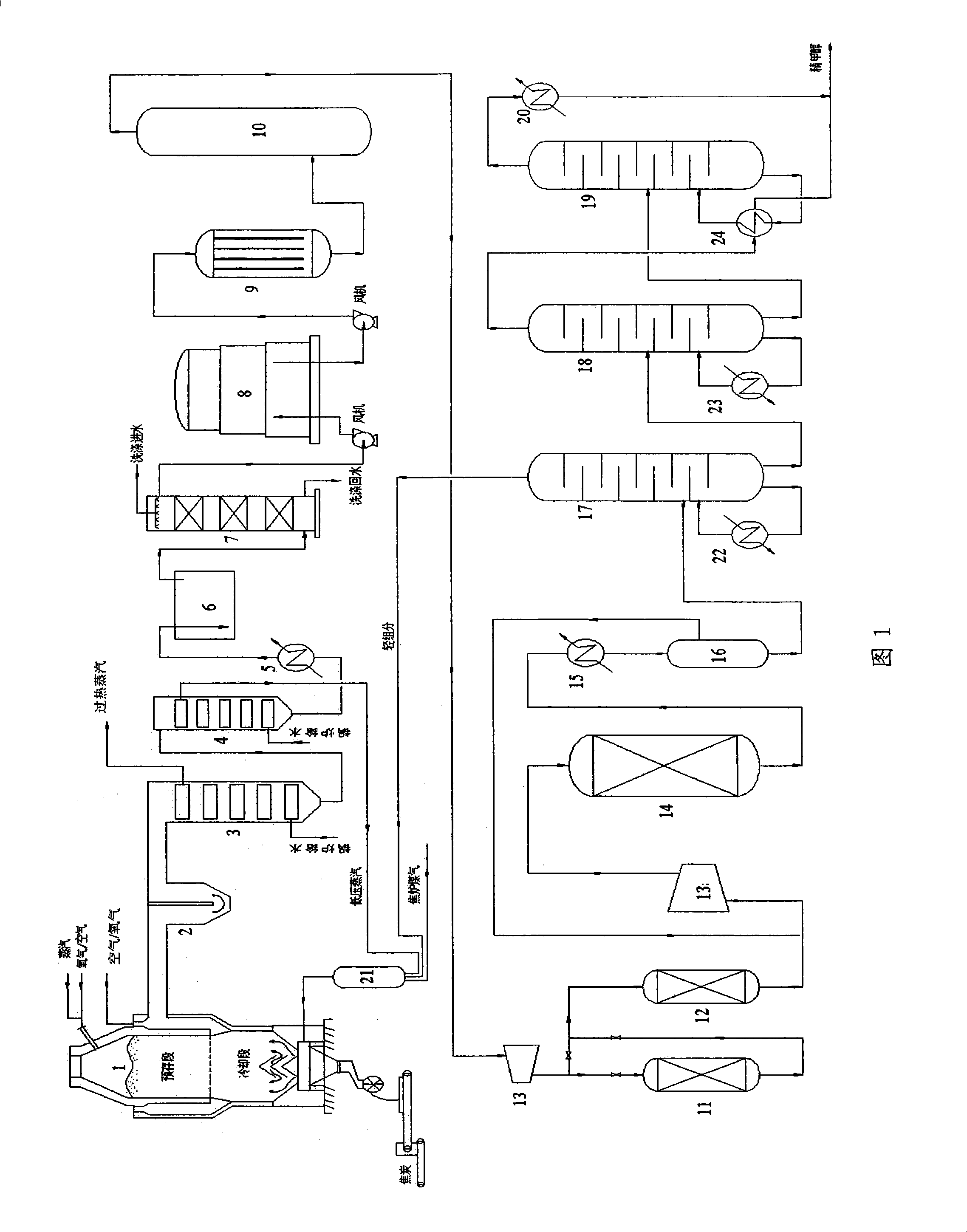

[0058] As shown in Figure 1. The volume of cooling section 1 of CDQ oven is 400m 3 , the volume of the pre-stored section is 300m 3 . Under the condition of an average coke yield of 150t / h, the red hot coke with an average temperature of 980°C was cooled. Low-pressure steam with a temperature of 120°C and a pressure of 0.2MPa is used as cooling gas, and is fed from the bottom of the cooling section of CDQ oven 1 at 15000Nm 3 / h (about 73t) is sprayed upwards, and the temperature rises after absorbing the sensible heat of the red coke during the rising process of the cooling section, and undergoes an endothermic chemical reaction with the red coke to form a temperature of 800°C and a pressure of 0.15MPa. The main components are CO and CO 2 、H 2 、H 2 O Syngas 16000Nm 3 / h.

[0059] The synthesis gas is removed from the water vapor sampling analysis results at room temperature as shown in the table below, and the converted synthesis gas volume is about 3000Nm 3 / h.

[00...

Embodiment 2

[0072] As shown in Figure 1. The same place as Embodiment 1 will not be repeated, the difference is that: the low-pressure steam produced by the low-pressure steam waste heat boiler 4 is introduced into the gas mixing tank 21, mixed with the coke oven gas from the coking process, and used as cooling gas from the cooling The steam nozzle at the bottom of the section blows into the mixed gas of low-pressure steam and coke oven gas 15000Nm 3 / h, the volume ratio of the low-pressure steam to coke oven gas is 5:1, the methane content is 20v%, the cooling gas temperature is 120°C, and the pressure is 0.2MPa. After the mixed gas of low-pressure steam and coke oven gas passes through the red coke layer, a crude synthesis gas of 18000Nm with a temperature of 800°C and a pressure of 0.15MPa is produced 3 / h. The results of water vapor sampling and analysis at room temperature are shown in the table below, and the converted synthesis gas volume is about 5000Nm 3 / h.

[0073] Composit...

Embodiment 3

[0082] The same place as in Embodiment 1 will not be described again, and the difference is that:

[0083] The temperature of the red coke entering the CDQ oven 1 is 900°C, and the temperature drops to 190°C after being CDQ by the cooling gas, and then it is discharged from the CDQ oven 1. Low-pressure steam with a temperature of 150°C and a pressure of 0.1 MPa is used as cooling gas, and is sprayed upward from the bottom of the cooling section of CDQ oven 1. During the rising process of the cooling section, the temperature rises after absorbing the sensible heat of red coke, and absorbs with red coke. The temperature of thermochemical reaction is 850℃, the pressure is 0.1MPa, and the main components are CO, CO 2 、H 2 of synthetic gas. The synthesis gas composition:

[0084] Composition (v%)

[0085] CO H 2 CH 4 N 2 CO 2 h 2 SO 2

[0086] 35 60 0.5 0.15 4 0.15 0.2

[0087] The synthesis gas is discharged from the upper part of the cooling section, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com