Device and method for blending waste plastics by residual oil hydrogenation device

A technology for hydrogenation of residual oil and waste plastics, applied in the petroleum industry, processing hydrocarbon oil, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of wasting plastic recycling value, environmental pollution, occupying valuable land resources, etc., and achieve the reduction of metal content and sulfur and nitrogen content, less investment in equipment, and prolonged catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

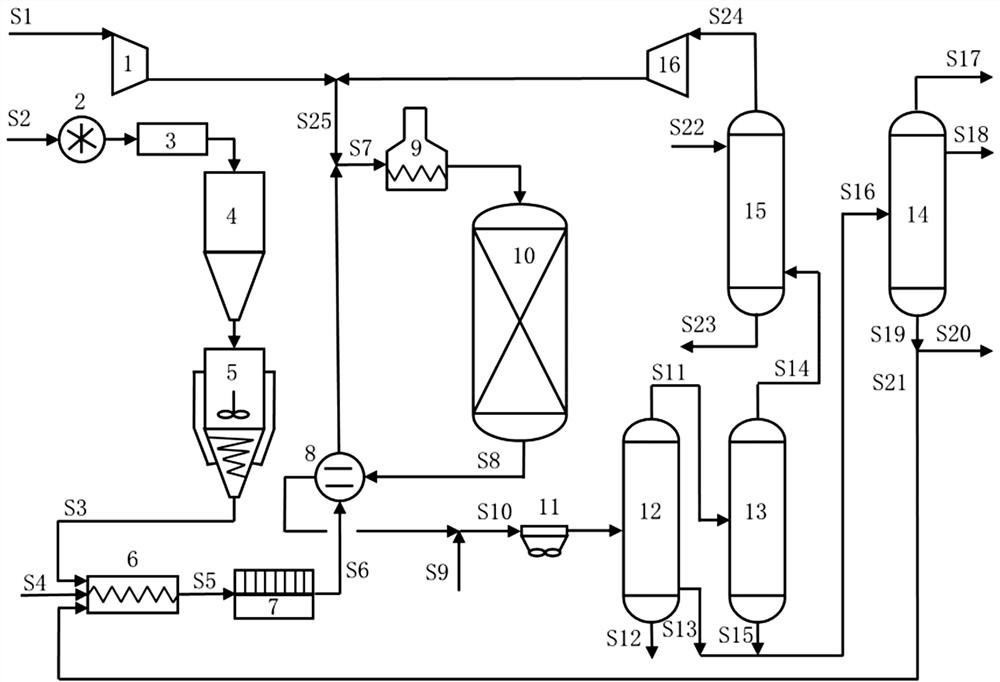

[0043] In this example, a fixed bed reactor is used for hydrocracking of residual oil-waste plastic mixed raw material. The waste plastic is a mixture of polyethylene (PE) and polypropylene (PP). The mass proportion of PE and PP in waste plastics is 60% and 40%, respectively. The main process parameters are shown in Table 1.

[0044] Process flow chart see figure 1 , figure 1 Medium logistics: S1-new hydrogen, S2-solid waste plastic, S3-melted waste plastic, S4-fresh residue, S5-residue plastic mixture, S6-filtered residue plastic mixture, S7-hydrogen mixed residue plastic mixture , S8-hydrogenation reaction effluent, S9-deoxygenated water, S10-water injection reaction effluent, S11-cold high fraction tank top gas, S12-acid sewage, S13-cold high fraction tank bottom oil, S14-cold low fraction Tank Top Gas, S15-Cold Low Fraction Tank Bottom Oil, S16-Mixed Tank Bottom Oil, S17-Fuel Gas and Wide Distillate Gasoline, S18-Middle Distillate Oil, S19-Broad Distillate Residue, S20-E...

Embodiment 2

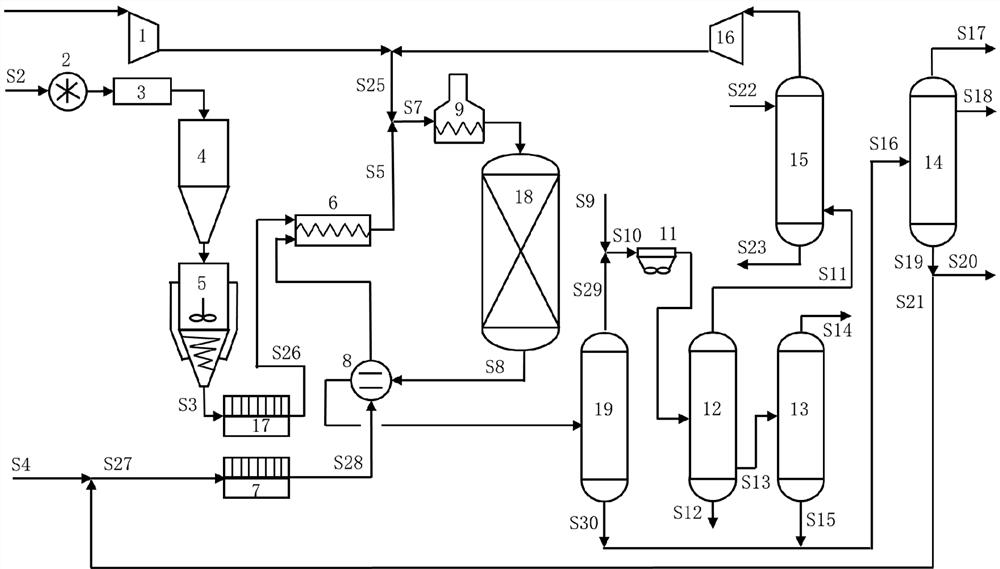

[0050] In this example, a fluidized bed reactor is used to hydrocrack the residual oil-waste plastic mixed raw material. The waste plastics are polyethylene (PE), polypropylene (PP), polyvinyl alcohol (PVA), polymethyl methacrylate ( PMMA) and polyvinyl chloride (PVC), the residual oil is vacuum residual oil, waste plastics accounted for 13.0% of raw materials, and the mass proportions of PE, PP, PVA, PMMA and PVC in waste plastics were 30.5%, 30.5%, 26.3%, 19.2%, 23.1% and 0.9%, the main process parameters are shown in Table 2.

[0051] figure 2 It is another schematic flow chart of the method of the present invention.

[0052] The logistics include: S1-new hydrogen, S2-solid waste plastic, S3-melted waste plastic, S4-fresh residue, S5-residue plastic mixture, S7-hydrogen mixed residue plastic mixture, S8-hydrogenation reaction effluent, S9-deoxygenated water, S10-water injection reaction effluent, S11-cold high fraction tank top gas, S12-acid sewage, S13-cold high fractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com