Granule curing agent and high-strength low-shrinkage cracking-resistance road surface base layer material prepared using same

A technology of curing agent and pellets, applied in the direction of cement production, etc., can solve the problems of insufficient mechanical properties and durability, and achieve the effect of increasing strength, increasing strength and reducing plastic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In the following examples, the low-Ca micro-expansion cement used has a density of 3200kg / m 3 , specific surface area 324m 2 / kg, the average particle size is 12.5 μm, and the specific preparation method comprises the following steps:

[0055] 1) With coal gangue, paper sludge, ash, CaO, MgO and BaCO 3 As the main raw material, each raw material is weighed according to the proportion, and the ball mill is mixed evenly to obtain the raw meal. The raw materials and their mass percentages include: coal gangue 64%, paper sludge 12%, ash 3%, analytically pure CaO 20 %, Analytical pure MgO 1.0%;

[0056] 2) adding water of 3% of the mass of the raw meal to the mixed material obtained in step 1) ball milling, continuing to mix evenly, and then pressing to obtain a raw meal tablet;

[0057] 3) Heat the obtained raw material pressed tablet to 1300°C and keep it warm for 40 minutes, then take it out and quench it in the air, and then grind it down to less than 0.075mm to obtai...

Embodiment 1

[0070] A granular solidifying agent and a high-strength, low-shrinkage anti-crack pavement base material prepared by using the same, the preparation process includes the following steps:

[0071] Granular curing agent

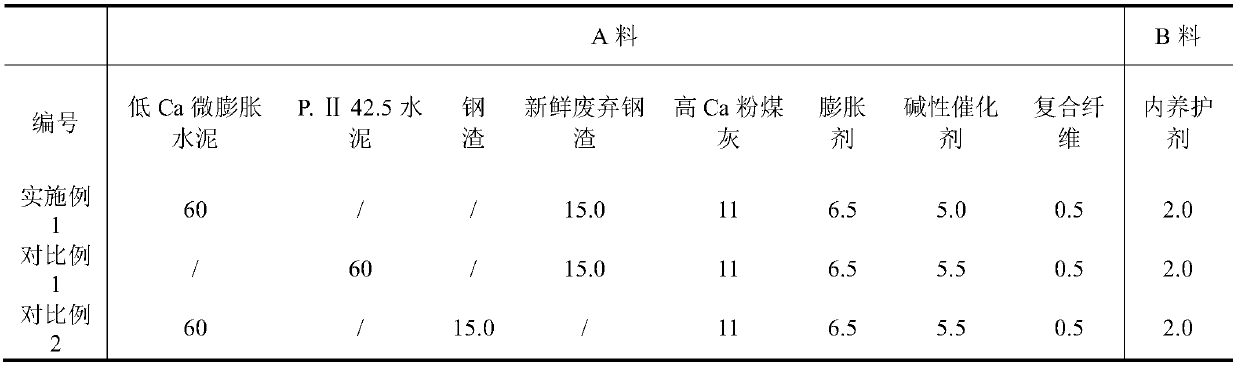

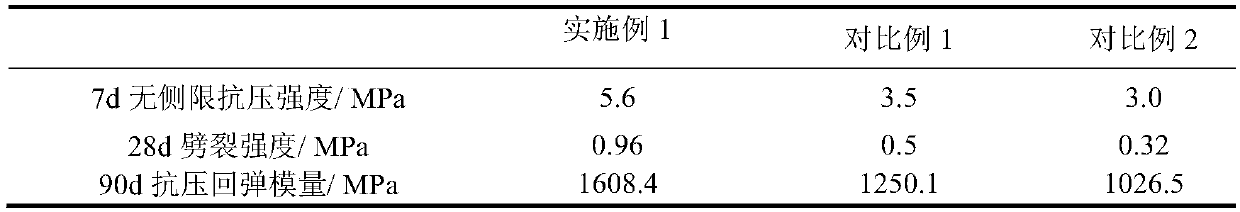

[0072] 1) Use low-Ca micro-expansion cement, alkaline catalyst, waste steel slag, high-Ca fly ash, expansion agent, composite fiber and internal curing agent as raw materials, and weigh each raw material according to the proportioning conditions described in Table 1-1;

[0073] 2) Use low-Ca micro-expansion cement, alkaline catalyst, fresh waste steel slag, high-Ca fly ash, expansion agent and fiber as material A, mix the components and grind them until the Blaine specific surface area is 650m 2 / kg; the internal curing agent is pre-wetted for material B;

[0074] High-strength and low-shrinkage anti-crack pavement base material

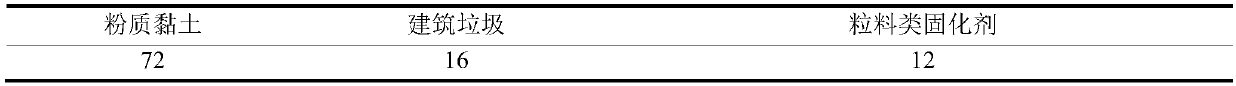

[0075] 1) With silty clay, granular solidifying agent and construction waste as raw materials, each raw material is weighed accord...

Embodiment 2-4

[0094] The preparation process of the granular solidifying agent and the high-strength low-shrinkage anti-crack pavement base material described in Example 2-4 is roughly the same as that of Example 1, except that the formulas used are specifically shown in Tables 2-1 and 2-2; See Table 2-3 for the test block strength test results of the high-strength and low-shrinkage anti-crack pavement base material, see Table 2-4 for the water stability test results, and see Table 2-5 for the crack resistance test results.

[0095] Table 2-1 Composition of granular curing agent / %

[0096]

[0097] Table 2-2 Composition and dosage of each raw material in pavement base material / %

[0098]

[0099] Table 2-3 Strength of pavement base material

[0100]

[0101] Table 2-4 Water Stability Coefficient of Stabilized Soil with Shrinkage Reinforcement Materials

[0102]

[0103] Table 2-5 Variation of drying shrinkage characteristics of stabilized soil with age

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com