Oil-soluble catalyst and preparation method thereof

An oil-soluble, catalyst technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low active metal content, need organic solvents and high temperature, etc. The effect of reducing coke yield, increasing conversion and light oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

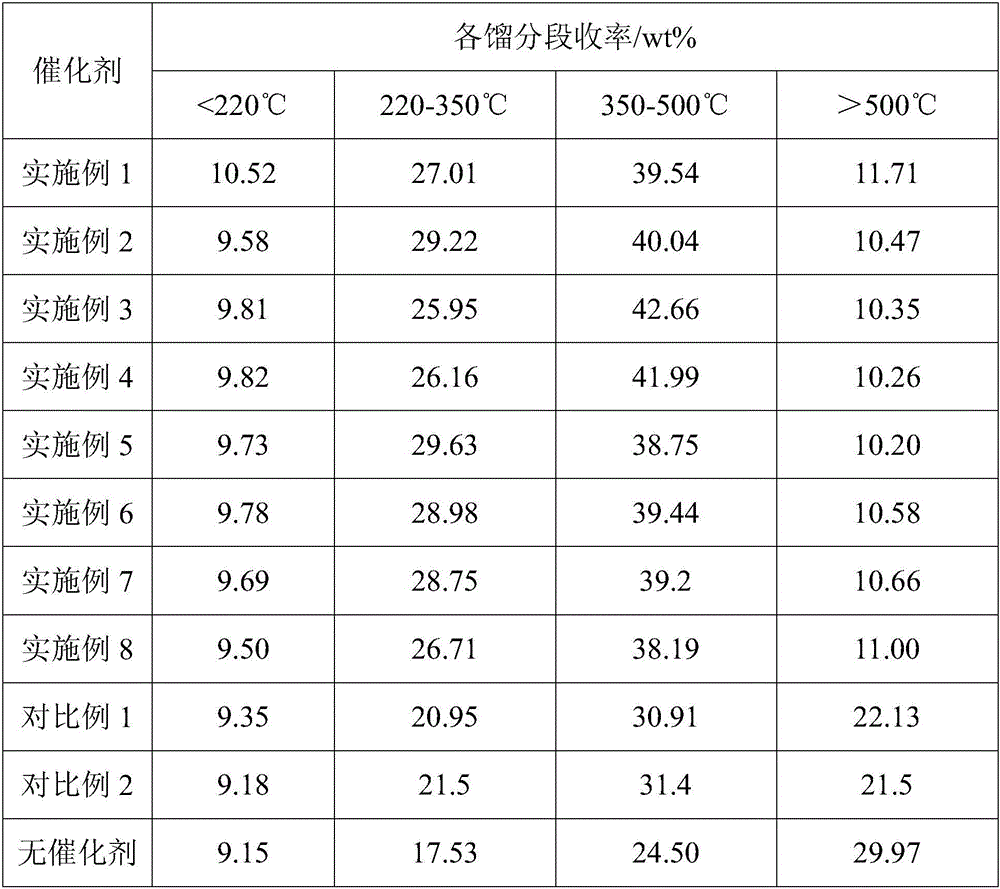

Embodiment 1

[0027] An oil-soluble catalyst and a preparation method thereof provided in this embodiment. The oil-soluble catalyst includes Mo and Ni, the total content of Mo and Ni is 25wt%, and the molar ratio of Mo and Ni is 1:1.

[0028] The preparation method of the oil-soluble catalyst provided by the present embodiment comprises the following steps:

[0029] 1) Molybdenum nitrate aqueous solution and nickel nitrate aqueous solution are mixed in a beaker according to the molar ratio of Mo and Ni therein at 1:1 to obtain a mixed solution;

[0030] 2) Add sodium hydroxide precipitating agent to the mixed solution until the pH of the reaction system=9.0, then stir and react at 40°C for 4 hours to form a precipitate, which is filtered, washed and dried to obtain molybdenum-nickel metal precursor;

[0031] 3) Mix the molybdenum-nickel metal precursor and hexadecanoic acid in a four-necked flask at a mass ratio of 1:10, and react at 150°C for 1 hour in an oxygen-free atmosphere. After th...

Embodiment 2

[0033]An oil-soluble catalyst and a preparation method thereof provided in this embodiment. The oil-soluble catalyst includes W and Co, the total content of W and Co is 15wt%, and the molar ratio of W and Co is 1:1.

[0034] The preparation method of the oil-soluble catalyst provided by the present embodiment comprises the following steps:

[0035] 1) Mix tungsten nitrate aqueous solution and cobalt nitrate aqueous solution in a beaker according to the molar ratio of W and Co in a beaker of 1:1 to obtain a mixed solution;

[0036] 2) Add ammonia water precipitant to the mixed solution until the pH of the reaction system is 8.0, then stir and react at 80°C for 2 hours to form a precipitate, which is filtered, washed, and dried to obtain a tungsten-cobalt metal precursor ;

[0037] 3) Mix the tungsten-cobalt metal precursor and hexaphosphonic acid in a four-necked flask at a mass ratio of 1:5, and react at 120°C for 6 hours in an oxygen-free atmosphere. After the reaction, tun...

Embodiment 3

[0039] An oil-soluble catalyst and a preparation method thereof provided in this embodiment. The oil-soluble catalyst includes Mo and Co, the total content of Mo and Co is 20wt%, and the molar ratio of Mo and Co is 5:1.

[0040] The preparation method of the oil-soluble catalyst provided by the present embodiment comprises the following steps:

[0041] 1) molybdenum nitrate aqueous solution and cobalt nitrate aqueous solution are mixed in a beaker according to the molar ratio of Mo and Co wherein 5:1, to obtain a mixed solution;

[0042] 2) Add ammonia water precipitant to the mixed solution until the pH of the reaction system is 9.5, then stir and react at 40°C for 5 hours to form a precipitate, which is filtered, washed and dried to obtain a molybdenum-nickel metal precursor ;

[0043] 3) The molybdenum-nickel metal precursor and tendecanoic acid were mixed in a four-necked flask at a mass ratio of 1:8, and reacted at 200°C for 8 hours in an oxygen-free atmosphere. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com