Clamping tool with magnetism and monitoring device adopting clamping tool

A magnetic device and magnetic technology, applied in the field of mechanical parts, can solve the problem that the monitoring device cannot work accurately, and achieve the effect of reducing manpower and material resources, reducing consumption, and ensuring accurate work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

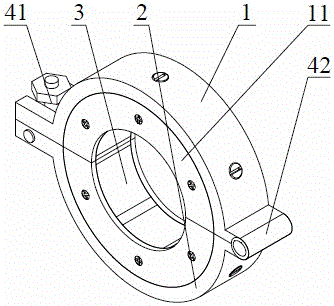

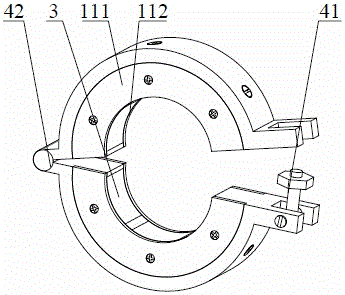

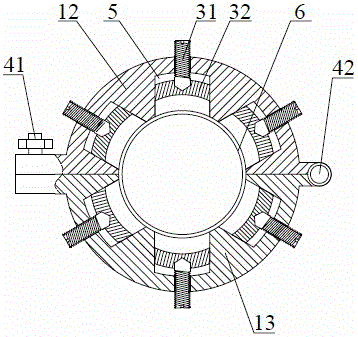

[0040] as attached figure 1 , attached figure 2 And attached image 3 As shown, the clamp with magnetism includes a clamping piece matched with the pipeline 6, and at least one chute 5 is arranged on the clamping piece, and the chute 5 is provided with a chute for absorbing metal impurities in the pipeline. The magnetic device 3 is capable of sliding along the sliding groove 5 .

[0041] The clamp with magnetism of the present application is provided with a chute 5 on the clamping piece, and a magnetic device 3 is set in the chute 5, so that when the clamping piece is clamped on the pipeline 6, the The magnetic device 3 can absorb metal impurities in the pipeline 6, so that the metal impurities accumulate in the pipeline 6 at the position corresponding to the clamping range of the clamping piece, so as to ensure that there are no metal impurities in the liquid after passing through the clamping range of the clamping piece, and avoid metal contamination. Impurities enter th...

Embodiment 2

[0052] as attached figure 1 , attached figure 2 And attached Figure 4 As shown, the principle of the clamp with magnetism of the present application is the same as that of Embodiment 1, the difference is that: the adjustment assembly also includes a connection block 33, and the connection block 33 is detachably connected with the magnetic clamp block 32, and the magnetic clamp The block 32 is limited in the chute 5 , and the adjusting rod 31 passes through the connecting block 33 along the radial direction of the pipe 6 . The magnetic clamping block 32 is limited to move in the direction of the chute 5 all the time by the connecting block 33, avoiding that when the magnetic clamping block 32 slides out of the chute 5 range, when the magnetic clamping block 32 is adjusted again and gets back in the chute 5, it is not easy to communicate with The cooperation of the chute 5 further facilitates the adjustment of the position of the magnetic clamping block 32 .

Embodiment 3

[0054] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, a monitoring device includes the clamp with magnetism described in Embodiment 1 and Embodiment 2.

[0055] The monitoring device of this embodiment adopts the above-mentioned clamp with magnetism. In actual use, when the monitoring device is installed on the infusion pipeline to work normally, the flowing liquid in the infusion pipeline first passes through the clamp with magnetism. Within the clamping range of the fixture, the magnetic fixture will adsorb the metal dust in the liquid to the inner wall of the pipe, preventing the metal dust from entering the monitoring device, so that the monitoring device that works on the magnetic principle will not be affected by the metal dust. Moreover, Due to the adjustable adsorption force of the magnetic clamp to the metal dust in the pipeline, different monitoring devices are equipped with different magnetic clamps, so that the sco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com