ni 2+ Preparation of Adsorbent and Its Adsorption Method

An adsorbent, NH2-SBA-15 technology, applied in the field of mesoporous materials, can solve problems such as secondary pollution, and achieve the effects of wide sources, good application prospects and low-cost coordination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

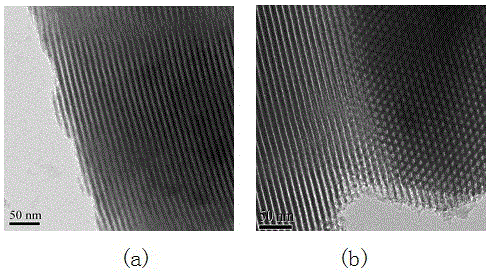

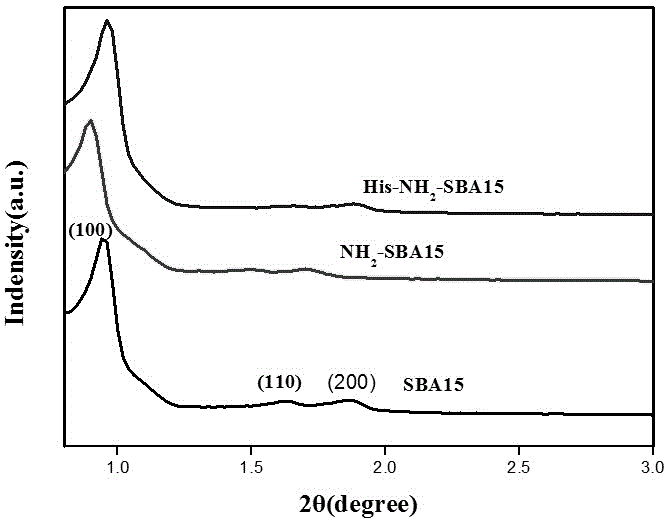

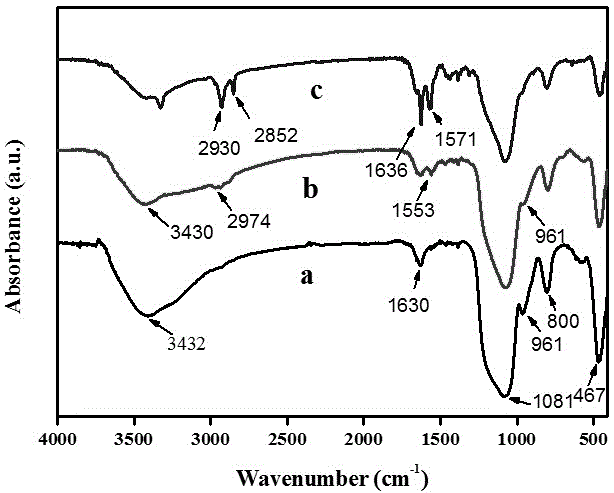

Image

Examples

Embodiment 1

[0022] At 40 °C, dissolve 4 g of P123 into 30 g of deionized water, and then add 120 g of 2 mol L -1 Stir vigorously with HCl; after 2 h, add 8.5 g tetraethyl orthosilicate dropwise, keep stirring at 40 °C for 20 h; then transfer the mixture into a closed reaction kettle, and crystallize at 105 °C for 24 h; , the obtained product was suction filtered, washed three times with absolute ethanol and deionized water; the obtained solid powder was extracted with absolute ethanol at 85 °C for 36 h, and then vacuum-dried at 85 °C for 4 h to obtain SBA-15; N 2 Under protection, 1 g of SBA-15 powder was dissolved in 30 mL of dry toluene, 1 mL of APTES was added dropwise, and refluxed at 110 °C for 18 h; the obtained product was filtered with suction and washed with toluene and absolute ethanol; the product Drying in vacuum at 70°C for 12 h gave NH 2 - SBA-15 powder; in N 2 Under protection, with dimethylformamide as solvent, add 0.5 g NH 2 -SBA-15, 2.5 g L-histidine, 7.5 g dicycloh...

Embodiment 2

[0026] The amino functionalization step of the silicon-based mesoporous material SBA-15 is the same as in Example 1; 2 Under protection, with dimethylformamide as solvent, add 0.5 g NH 2 -SBA-15, 2.5 g L-methionine, 7.5 g dicyclohexylcarbodiimide and 0.5 g 4-dimethylaminopyridine, the reaction temperature was 85 °C, and the reaction time was 60 h; the product was suction filtered, Washing with dimethylformamide and absolute ethanol in sequence, and drying, the obtained product is the L-methionine-modified silicon-based mesoporous material, denoted as Met-SBA-15.

[0027] Measure Ni 2+ The content is 100 mg·L -1 50mL of electroplating wastewater, use 0.1 mol·L -1 NaOH solution was adjusted to pH 5.0, placed in a 250 mL Erlenmeyer flask, added 40 mg of Met-SBA-15, and shaken at 30 °C for 10 min; 2+ The equilibrium adsorption capacity is 88 mg·g -1 , the adsorption experiment results show that L-methionine modified silicon-based mesoporous material Met-SBA-15 2+ Ions have ...

Embodiment 3

[0029] The amino functionalization step of the silicon-based mesoporous material SBA-15 is the same as in Example 1; 2 Under protection, with dimethylformamide as solvent, add 0.5 g NH 2 -SBA-15, 2.5 g L-cysteine, 7.5 g dicyclohexylcarbodiimide, and 0.5 g 4-dimethylaminopyridine, the reaction temperature was 85 °C, and the reaction time was 50 h; the product was suction filtered, Washing with dimethylformamide and absolute ethanol in sequence, and drying, the obtained product is the L-cysteine modified silicon-based mesoporous material, denoted as Cys-SBA-15.

[0030] Measure Ni 2+ The content is 100 mg·L -1 50mL of printing and dyeing wastewater, use 0.1 mol·L -1 NaOH solution was adjusted to pH 4.0, placed in a 250 mL Erlenmeyer flask, added 30 mg of Cys-SBA-15, and shaken at 25 °C for 20 min; 2+ The equilibrium adsorption capacity is 74 mg·g -1 , the results of adsorption experiments showed that the L-cysteine modified silicon-based mesoporous material Cys-SBA-15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com