Modified lanthanide-series-metal organic framework material and preparation method thereof

A lanthanide metal and organic framework technology, applied in non-metallic elements, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of small hydrogen storage at room temperature, and achieve the effect of increasing the hydrogen storage at room temperature and changing the adsorption process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the present invention may also include activation treatment. Activation treatment may follow drying. The purpose of the activation treatment is to discharge the solvent molecules (such as water, the solvent used for grinding, etc.) in the micropores of the prepared material on the one hand, so that the active ingredient palladium component is more conducive to exerting its effect. On the other hand, activation can also increase the apparent density of the material, for example, it can be increased from 0.1-0.2g / cm3 to 0.2-0.5g / cm3 3 ; Of course, the BET specific surface area can also be increased to a certain extent. The activation method adopts the known gas flow method, that is, the gas flow is used as the adsorbate, where the gas flow can be one or at least two of nitrogen flow, helium flow, and argon flow.

[0032] The activation temperature is preferably 190-210°C, such as 190°C, 195°C, 200°C, 205°C, 210°C, preferably 200°C. Excessively...

Embodiment 1

[0034] Preparation of lanthanide metal organic framework material TbBTC: 0.28mmol Tb(NO 3 ) 3 ·6H 2 O and 0.02g (0.1mmol) H 3 BTC was mixed, and 4ml DMF, 4ml ethanol and 3.2ml HO were added 2 O, stirred at room temperature for 1 h until clear and transparent, then heated to 80 °C in air at a rate of 1 °C / min, and kept for 24 h, then cooled down to room temperature naturally. The yield of the obtained sample was about 37.9%. Elemental analysis: C is 21.98%; H is 1.17%; N is 1.29%.

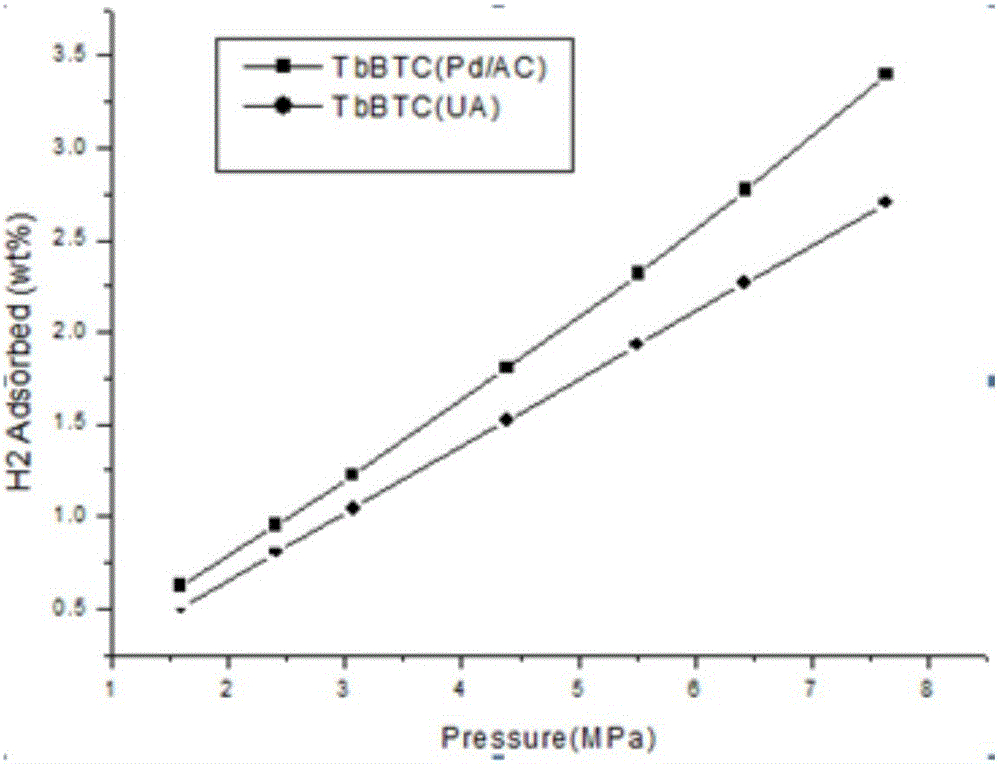

[0035] The above-mentioned TbBTC lanthanide metal organic framework material and a palladium content of 2wt% are the Pd / AC catalyst powder ratio, and the catalyst Pd accounts for 0.334% of the total mass of the two, calculated as palladium. After mixing the two evenly, add ethanol, disperse by ultrasonic vibration for 20 minutes, let it dry naturally after being uniform, put it in a vacuum drying oven, and dry at 100°C for 3 hours to obtain the modified lanthanide metal organic framework materi...

Embodiment 2

[0037] Preparation of lanthanide metal organic framework material ErBTC: 0.28mmol Er(NO 3 ) 3 ·6H 2 O and 0.02g (0.1mmol) H 3 BTC was mixed, and 4ml DMF, 4ml ethanol and 3.2ml HO were added 2 O, stirred at room temperature for 1 h until clear and transparent, then heated to 80 °C in air at a rate of 1 °C / min, and kept for 24 h, then cooled down to room temperature naturally. The yield of the obtained sample was about 42.9%. Elemental analysis: C is 30.16%; H is 2.50%; N is 3.82%.

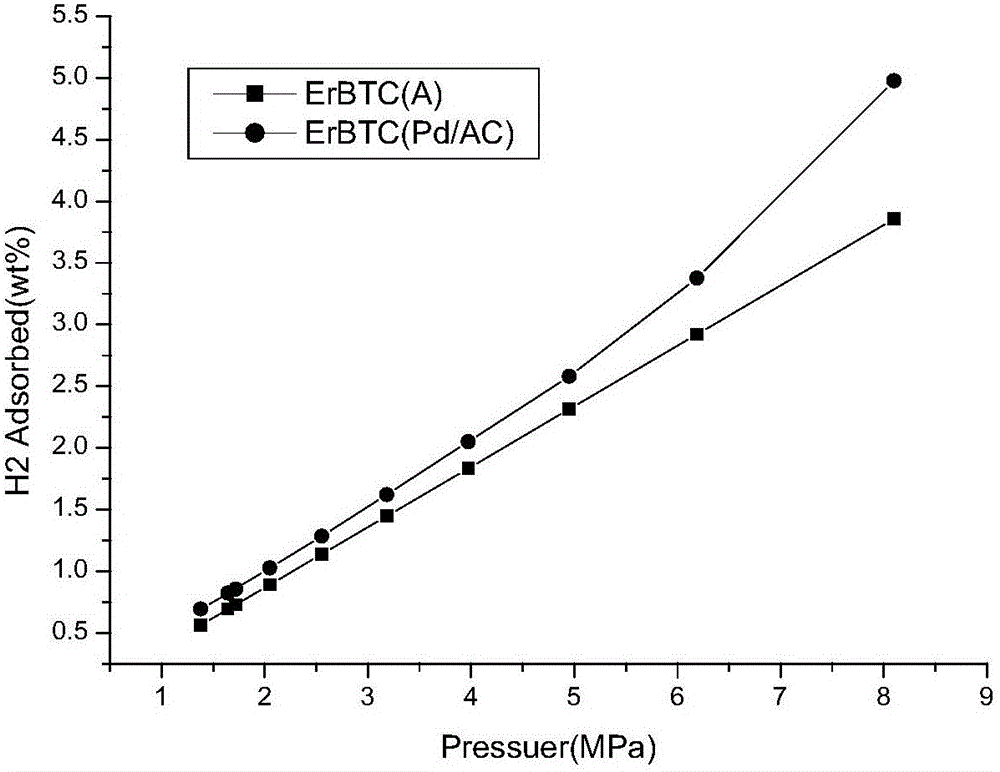

[0038] The ErBTC lanthanide metal-organic framework material and the palladium content of 2wt% are used as the Pd / AC catalyst powder ratio, and the catalyst Pd accounts for 0.334% of the total mass of the two, calculated as palladium. After mixing the two evenly, add ethanol, disperse by ultrasonic vibration for 20 minutes, let it dry naturally after being uniform, put it in a vacuum drying oven, and dry at 100°C for 3 hours to obtain the modified lanthanide metal organic framework material. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com