Modified IRMOF-1 material and preparation method thereof

An IRMOF-1, modified technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of small hydrogen storage at room temperature, and achieve the effect of increasing the hydrogen storage at room temperature and changing the adsorption process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of IRMOF-1 material: 1.19g (4mmol) Zn(NO 3 ) 2 4H2O and 0.34g (2mmol) H 2 BDC (terephthalic acid) was mixed, dissolved in 40ml of dimethylformamide (DMF) at room temperature, 3 drops of hydrogen peroxide was added, and 2.3ml of triethylamine was slowly added and stirred for 1h, then heated under sealed conditions After reacting for 24 hours at 100°C, a colorless block crystal was obtained. After washing three times with DMF and absolute ethanol, they were dried in air at 80°C. Then, in a vacuum environment, the temperature was raised to 180°C at a rate of 1°C / min and kept for 12h. The yield of the obtained sample is about 80% (0.627g), the quantitative formula of the sample is Zn4O(C8H4O4)3·H2O, the elemental analysis result is: Zn, 33.07; C, 36.52%; the calculation result is: Zn, 33.08; C, 36.64%.

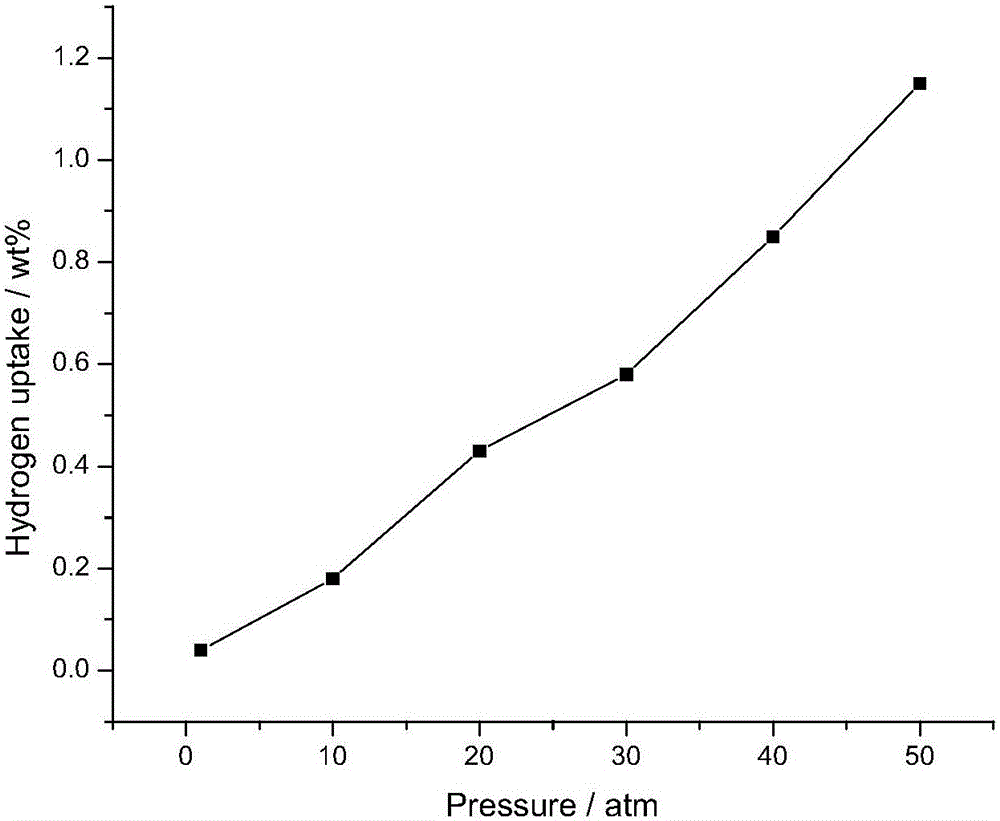

[0034] The above-mentioned IMROF-1 material and palladium content of 5wt% are the Pd / AC catalyst powder ratio, and the catalyst Pd accounts for 5% of the t...

Embodiment 2

[0036] Preparation of IRMOF-1 material: 1.19g (4mmol) Zn(NO 3 ) 2 4H 2 O and 0.34g (2mmol) H 2 BDC (terephthalic acid) was mixed, dissolved in 40ml of dimethylformamide (DMF) at room temperature, 3 drops of hydrogen peroxide was added, and 2.3ml of triethylamine was slowly added and stirred for 1h, then heated under sealed conditions After reacting for 24 hours at 100°C, a colorless block crystal was obtained. After washing three times with DMF and absolute ethanol, they were dried in air at 80°C. Then, in a vacuum environment, the temperature was raised to 180°C at a rate of 1°C / min and kept for 12h. The yield of the obtained sample is about 80% (0.627g), the quantitative formula of the sample is Zn4O(C8H4O4)3·H2O, the elemental analysis result is: Zn, 33.07; C, 36.52%; the calculation result is: Zn, 33.08; C, 36.64%.

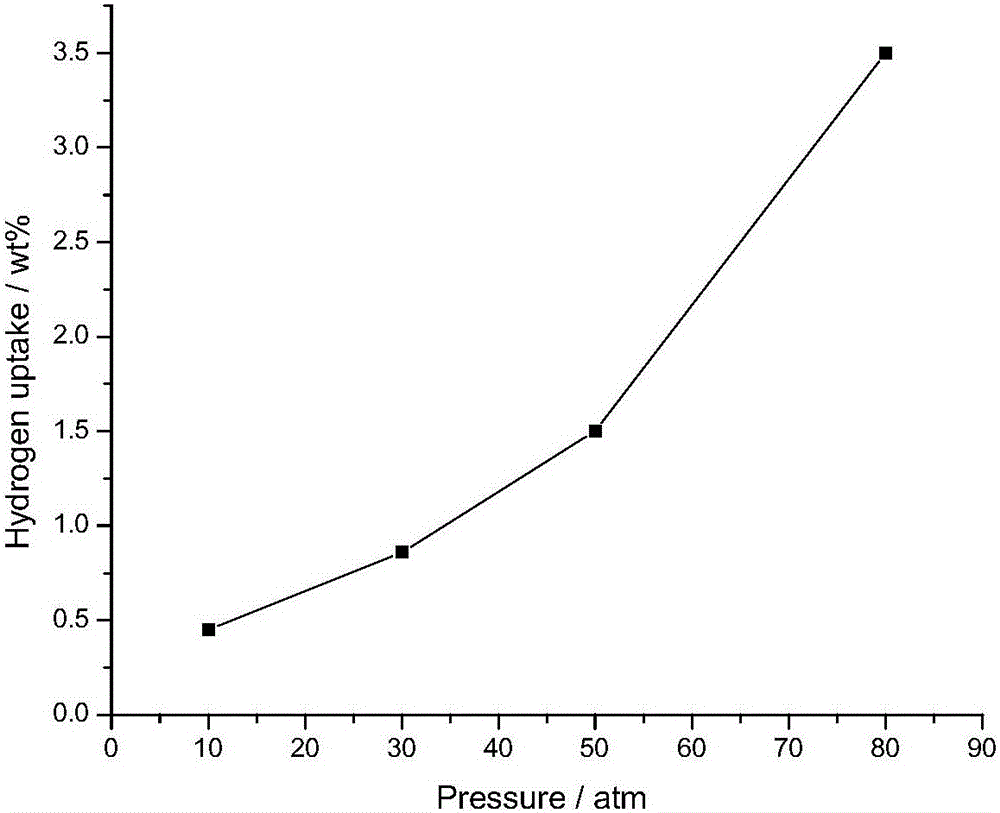

[0037]The above-mentioned IMROF-1 material and a palladium content of 15wt% are the Pd / AC catalyst powder ratio, and the catalyst Pd accounts for 0.5% o...

Embodiment 3

[0039] Preparation of IRMOF-1 material: 1.19g (4mmol) Zn(NO 3 ) 2 4H 2 O and 0.34g (2mmol) H 2 BDC (terephthalic acid) was mixed, dissolved in 40ml of dimethylformamide (DMF) at room temperature, 3 drops of hydrogen peroxide was added, and 2.3ml of triethylamine was slowly added and stirred for 1h, then heated under sealed conditions After reacting for 24 hours at 100°C, a colorless block crystal was obtained. After washing three times with DMF and absolute ethanol, they were dried in air at 80°C. Then, in a vacuum environment, the temperature was raised to 180°C at a rate of 1°C / min and kept for 12h. The productive rate of obtained sample is about 80% (0.627g), and the quantitative formula of sample is Zn 4 O(C 8 h 4 o 4 ) 3 ·H 2 O, elemental analysis result: Zn, 33.07; C, 36.52%; calculated result: Zn, 33.08; C, 36.64%.

[0040] The above-mentioned IMROF-1 material and palladium content of 10wt% are the Pd / AC catalyst powder ratio, and the catalyst Pd accounts for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com