Wall-climbing robot and working method thereof

A wall-climbing robot and robot technology, applied in the field of robotics, can solve problems such as unstable work, robot falling, and robot falling off, and achieve the effect of preventing wall-climbing robots from falling and preventing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

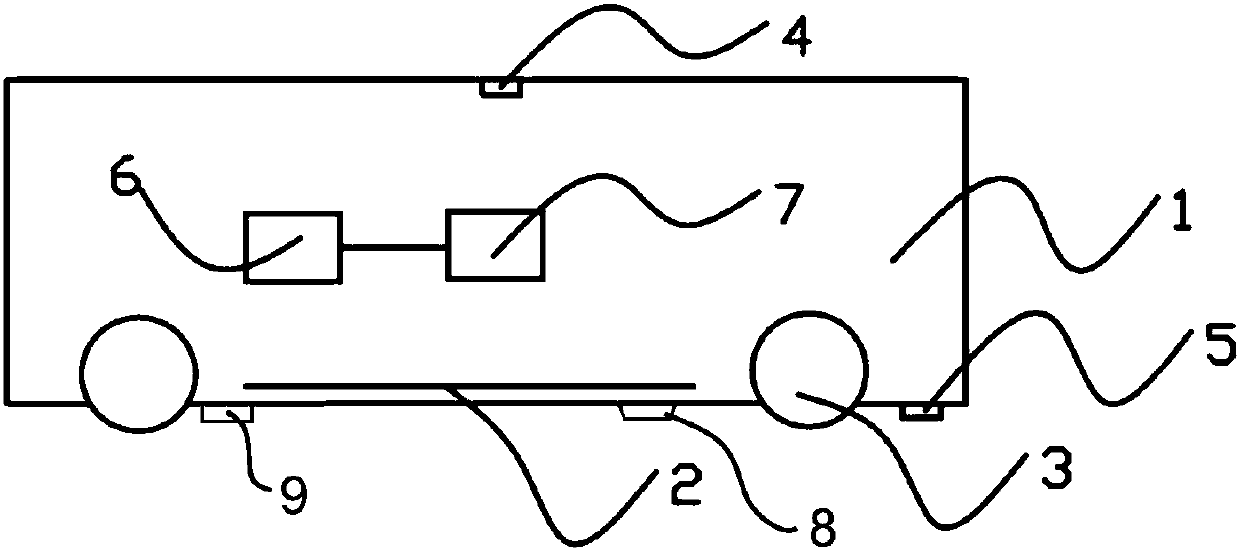

[0036] Such as figure 1 and figure 2 As shown, the present embodiment provides a wall-climbing robot, including:

[0037] The main body 1, the electromagnet 2 arranged at the bottom of the main body, the roller 3 used to drive the main body to move, and the controller 6; the controller is suitable for controlling the electromagnet 2 to be adsorbed on the surface of the magnetic conductor, and controls the rotation of the roller through the roller driving module , so that the wall-climbing robot realizes the wall-climbing action.

[0038] Wherein the controller can adopt a single-chip microcomputer, and the controller is suitable for controlling a current regulating module to change the operating current of the electromagnet. For example, the current regulating module can use a switching tube, and the single-chip microcomputer outputs a PWM signal to control the switching off of the switching tube. The cycle further realizes the adjustment of the working current; the body al...

Embodiment 2

[0052] On the basis of Embodiment 1, Embodiment 2 provides a working method of the wall-climbing robot described in Embodiment 1.

[0053] The working principle and process of each part of the magnetic suction welding robot in this embodiment are discussed in detail in Embodiment 1.

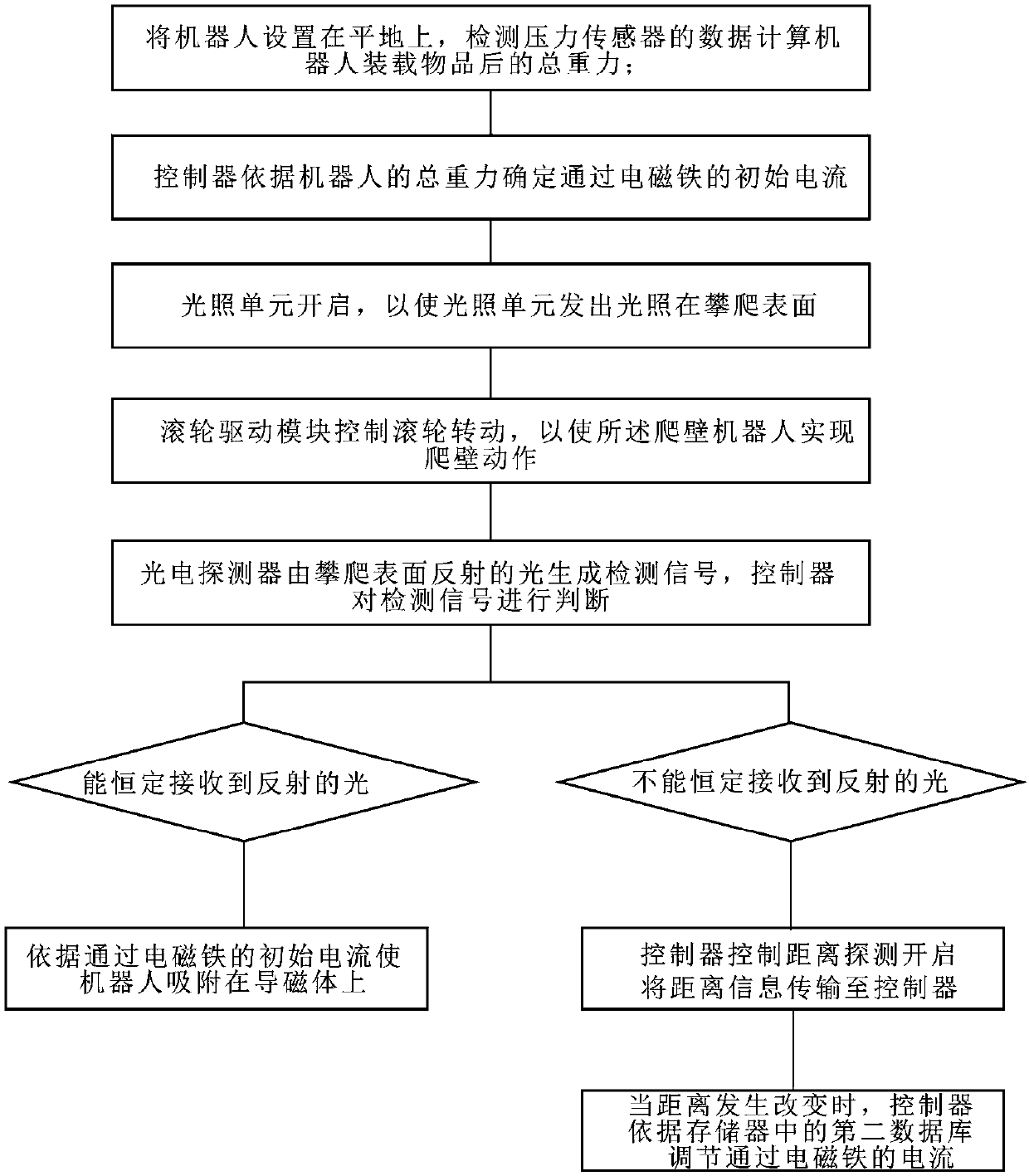

[0054] The invention provides a working method of a wall-climbing robot, comprising the following steps:

[0055] Step S01, when the robot is ready to work, first set the robot on the flat ground, detect the data of the pressure sensor and transmit it to the controller, and the controller calculates the total gravity of the robot after loading the objects based on the data of the pressure sensor and stores it in the memory;

[0056] Wherein, the first database in which the total load matches the electromagnet current is pre-stored in the memory, and the second database in which the distance between the bottom of the body and the surface of the crawling magnetizer matches the electromagnet current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com