Mercaptan removal catalyst as well as preparation method and application thereof

A catalyst and sweetening technology, applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as the inability to reduce the total sulfur content, reduce the heat effect of adsorption, reduce operational risks, and enhance chemical adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

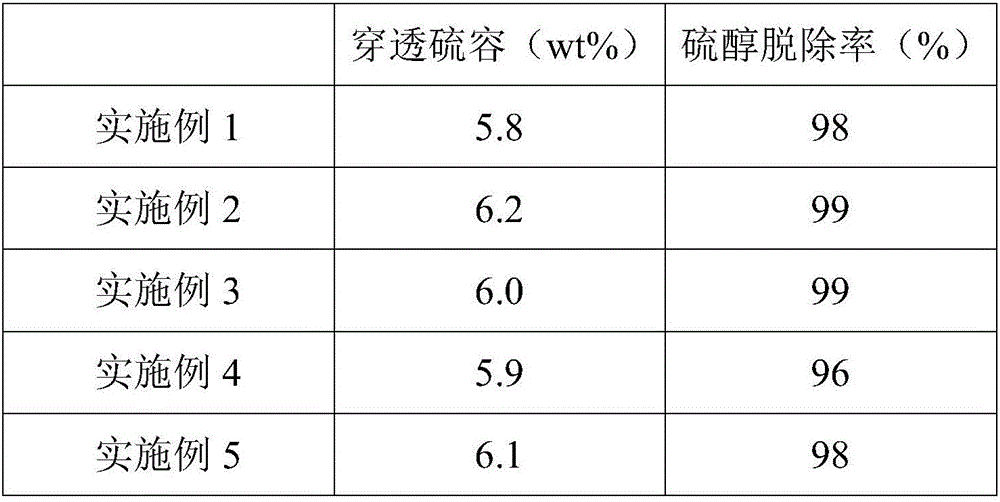

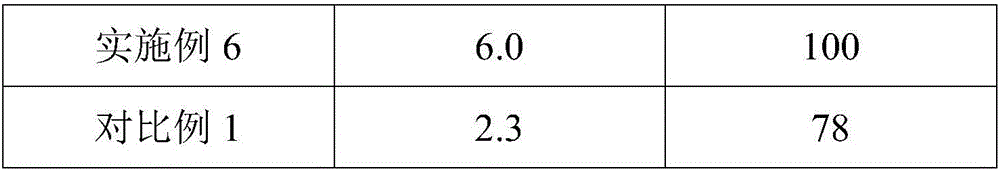

Examples

Embodiment 1

[0043] The preparation method of the sweetening catalyst provided by the present embodiment comprises the following steps:

[0044] (1) Modification of molecular sieve

[0045] Disperse 13X molecular sieve into 0.5mol / L cerium nitrate aqueous solution (mass ratio of molecular sieve to cerium = 1:10), perform ion exchange at 25°C, filter after reacting for 6h, collect solid phase, and Dry at 100°C for 2 hours, and then bake at 400°C for 6 hours to prepare cerium-modified molecular sieves;

[0046] (2) Preparation of carrier

[0047] The cerium-modified molecular sieve that step (1) makes and macroporous alumina dry rubber powder (pore volume > 1cm 3 / g, specific surface area>300m 2 / g) mixed at a mass ratio of 1:0.5, then added an appropriate amount of silica sol and starch to form a mixture, extruded the mixture, dried at 90°C for 3 hours, and then roasted at 400°C for 3 hours to obtain a carrier;

[0048] (3) Loading of active components

[0049] Prepare an aqueous solut...

Embodiment 2

[0054] The preparation method of the sweetening catalyst provided by the present embodiment comprises the following steps:

[0055] (1) Modification of molecular sieve

[0056] Disperse NaY molecular sieve into 0.1mol / L europium nitrate aqueous solution (mass ratio of molecular sieve to europium=1:12), and perform ion exchange at 50°C, filter after reacting for 5h, collect solid phase, and Dry at 110°C for 1 hour, and then bake at 500°C for 3.5 hours to prepare europium-modified molecular sieves;

[0057] (2) Preparation of carrier

[0058] With the europium-modified molecular sieve that step (1) makes and macroporous alumina dry rubber powder (pore volume > 1cm 3 / g, specific surface area>300m 2 / g) mixed at a mass ratio of 1:0.8, then added an appropriate amount of silica sol and starch to form a mixture, extruded the mixture, dried at 100°C for 3 hours, and then roasted at 500°C for 3 hours to obtain a carrier;

[0059] (3) Loading of active components

[0060] Prepare...

Embodiment 3

[0065] The preparation method of the sweetening catalyst provided by the present embodiment comprises the following steps:

[0066] (1) Modification of molecular sieve

[0067] Disperse NaY molecular sieve into 0.7mol / L lanthanum nitrate aqueous solution (mass ratio of molecular sieve to lanthanum = 1:8), perform ion exchange at 80°C, filter after reacting for 7h, collect solid phase, and Dry at 90°C for 3 hours, and then bake at 600°C for 1 hour to prepare lanthanum-modified molecular sieves;

[0068] (2) Preparation of carrier

[0069] The lanthanum-modified molecular sieve that step (1) makes and macroporous alumina dry rubber powder (pore volume > 1cm 3 / g, specific surface area>300m 2 / g) mixed at a mass ratio of 1:0.7, then added an appropriate amount of silica sol and starch to form a mixture, extruded the mixture, dried at 90°C for 3 hours, and then roasted at 500°C for 4 hours to obtain a carrier;

[0070] (3) Loading of active components

[0071] Prepare the aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com