Cerium-tin-zirconium composite oxide catalyst, and preparation method and use thereof

A technology of composite oxides and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of reducing industrial production costs, disadvantages, and high prices. Achieve the effect of low cost, wide temperature window range and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

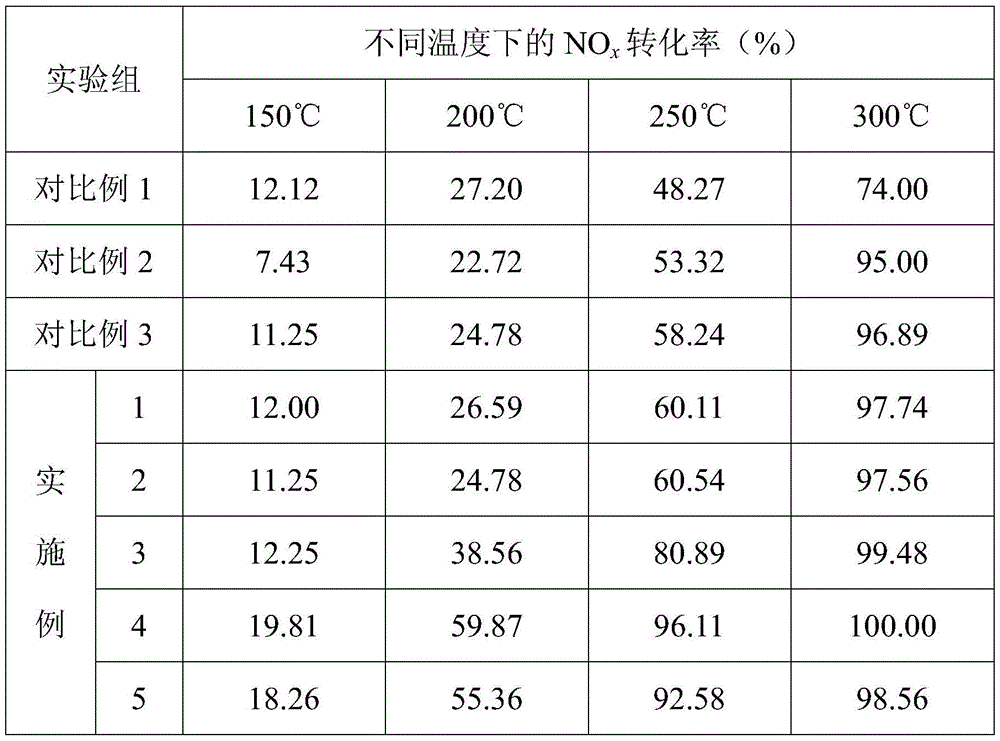

Embodiment 1

[0040] First dissolve cerium nitrate and zirconium nitrate completely in deionized water, then slowly add quantitative SnCl 4 and urea, wherein the molar ratio of urea to total metal ions is 10:1, and finally deionized water is added to the above mixed solution to a total volume of 250ml, and continuously stirred for 12h in a water bath at 90°C. After the above mixed solution is cooled to room temperature, the obtained precipitate is fully suction-filtered and washed to neutral with deionized water, then dried in an oven at 100°C overnight, and finally roasted at 500°C for 3 hours to obtain cerium tin-zirconium Composite oxide catalyst having the following chemical composition: CeSn a Zr 2 o x , a is 0.5.

Embodiment 2

[0042] Other conditions are the same as embodiment 1, except that adding control catalyst by raw material is composed of: CeSn a Zr 2 o x , a is 1.0.

Embodiment 3

[0044] Other conditions are the same as embodiment 1, except that adding control catalyst by raw material is composed of: CeSn a Zr 2 o x , a is 1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com