Waterborne acrylic resin capable of absorbing and degrading formaldehyde and preparation method thereof

A water-based acrylic acid, adsorption and degradation technology, applied in the field of water-based acrylic resin, can solve the problems of affecting the performance of coatings, harsh conditions, long time, etc., and achieve the effect of high viscosity, good film-forming performance, and changing photocatalytic degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

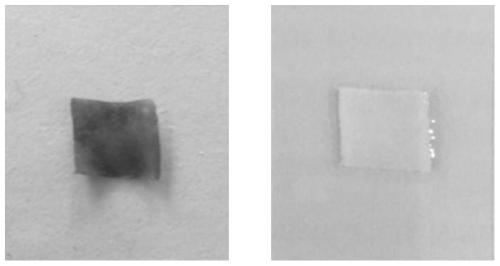

Image

Examples

Embodiment 1

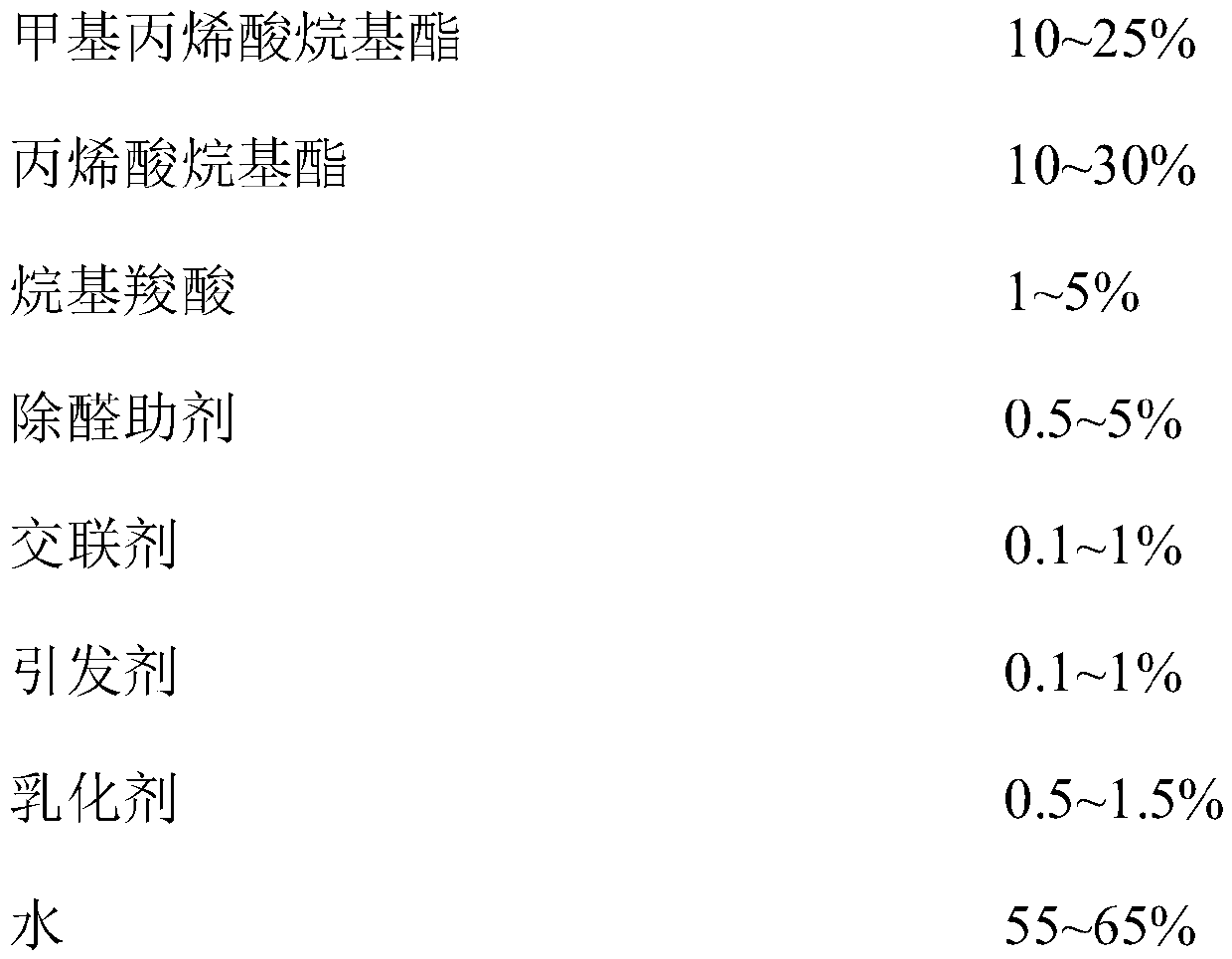

[0034] A kind of water-based acrylic resin that can adsorb and degrade formaldehyde, its component includes methyl methacrylate, butyl acrylate, methacrylic acid, p-divinylbenzene and acrylamide, and its specific formula is as follows:

[0035]

[0036] The preparation method of the water-based acrylic resin capable of absorbing and degrading formaldehyde, the steps are as follows:

[0037] 1), in terms of mass percentage, first mix the alkyl methacrylate, alkyl acrylate, alkyl carboxylic acid and crosslinking agent in the raw material formula to make mixed monomer; The initiator is dissolved in deionized water accounting for 30% of the total mass of the emulsifier and the emulsifier accounting for 50% of the total mass of the emulsifier to prepare a first solution. According to the FOX formula, the Tg of the copolymer composed of mixed monomers is 6°C;

[0038] 2) Preparation of seed emulsion: Add the remaining water, initiator and emulsifier into the reactor, stir and di...

Embodiment 2

[0044] A waterborne acrylic resin capable of adsorbing and degrading formaldehyde comprises propyl methacrylate, ethyl acrylate, methacrylic acid, o-divinylbenzene, N,N-methylenebisacrylamide (MBA), and its specific composition The distribution is as follows:

[0045]

[0046]

[0047] The preparation method of the water-based acrylic resin capable of absorbing and degrading formaldehyde, the steps are as follows:

[0048] 1), in terms of mass percentage, first mix the alkyl methacrylate, alkyl acrylate, alkyl carboxylic acid and crosslinking agent in the raw material formula to make mixed monomer; 40% of the mass of the total emulsifier of the initiator is dissolved in deionized water accounting for 20% of the total mass of water to prepare a first solution. According to the FOX formula, the Tg of the copolymer composed of mixed monomers is 8°C;

[0049] 2) Preparation of seed emulsion: Add the remaining water, emulsifier and initiator into the reactor, stir and dispe...

Embodiment 3

[0055] A kind of waterborne acrylic resin that can absorb and degrade formaldehyde comprises hexyl methacrylate, hexyl acrylate, methacrylic acid, o-divinylbenzene, adipate dihydrazide (ADH), and its concrete component formula is as follows:

[0056]

[0057] The preparation method of the water-based acrylic resin capable of absorbing and degrading formaldehyde, the steps are as follows:

[0058] 1), in terms of mass percentage, first mix the alkyl methacrylate, alkyl acrylate, alkyl carboxylic acid and cross-linking agent in the raw material formula to make mixed monomers; then account for 45% of the initiator mass 55% of the total emulsifier mass of the initiator was dissolved in deionized water accounting for 35% of the total water mass to prepare the first solution. According to the FOX formula, the Tg of the copolymer composed of mixed monomers=5°C;

[0059] 2) Preparation of seed emulsion: Add the remaining water, emulsifier and initiator into the reactor, stir and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com