Device and method for transforming physical characteristics of coal seam through downhole heat injection

A technology of physical properties and coal seams, which is applied in earthwork drilling, wellbore/well components, mining fluids, etc., can solve problems such as rock burst coal and gas, and change the physical properties of coal seams, so as to prevent rock burst or coal and coal gas highlight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

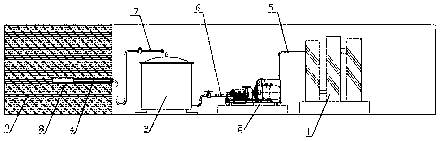

[0026] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

[0027] Such as figure 1 As shown, a device for underground heat injection to reform the physical characteristics of coal seams, including: a coal mine neutral water purification-softener 1, a high-pressure water pump 2, an electric heater 3, and a sealing pipe 4, the coal mine neutral water purification-softening The device 1 is connected to the high-pressure water pump 2 through a pipeline 5, the high-pressure water pump 2 is connected to the electric heater 3 through a high-pressure pipeline 6, and the electric heater 3 is connected to the sealing pipe through a heat injection pipeline 7. 4 connection, the sealing pipe 4 is set in the heat injection borehole 8 of the coal seam 9 .

[0028] The pressure of the electric heater 3 is 50±5MPa, and the temperature of the steam or superheated water output by the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com