Preparation method of activated carbon

A technology of activated carbon and carbonization, applied in the field of activated carbon, can solve the problems of poor wear resistance and compressive strength, difficulty in forming activated carbon, and difficult separation of activated carbon, etc., and achieve the effect of improving adsorption performance, reducing adsorption effect and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

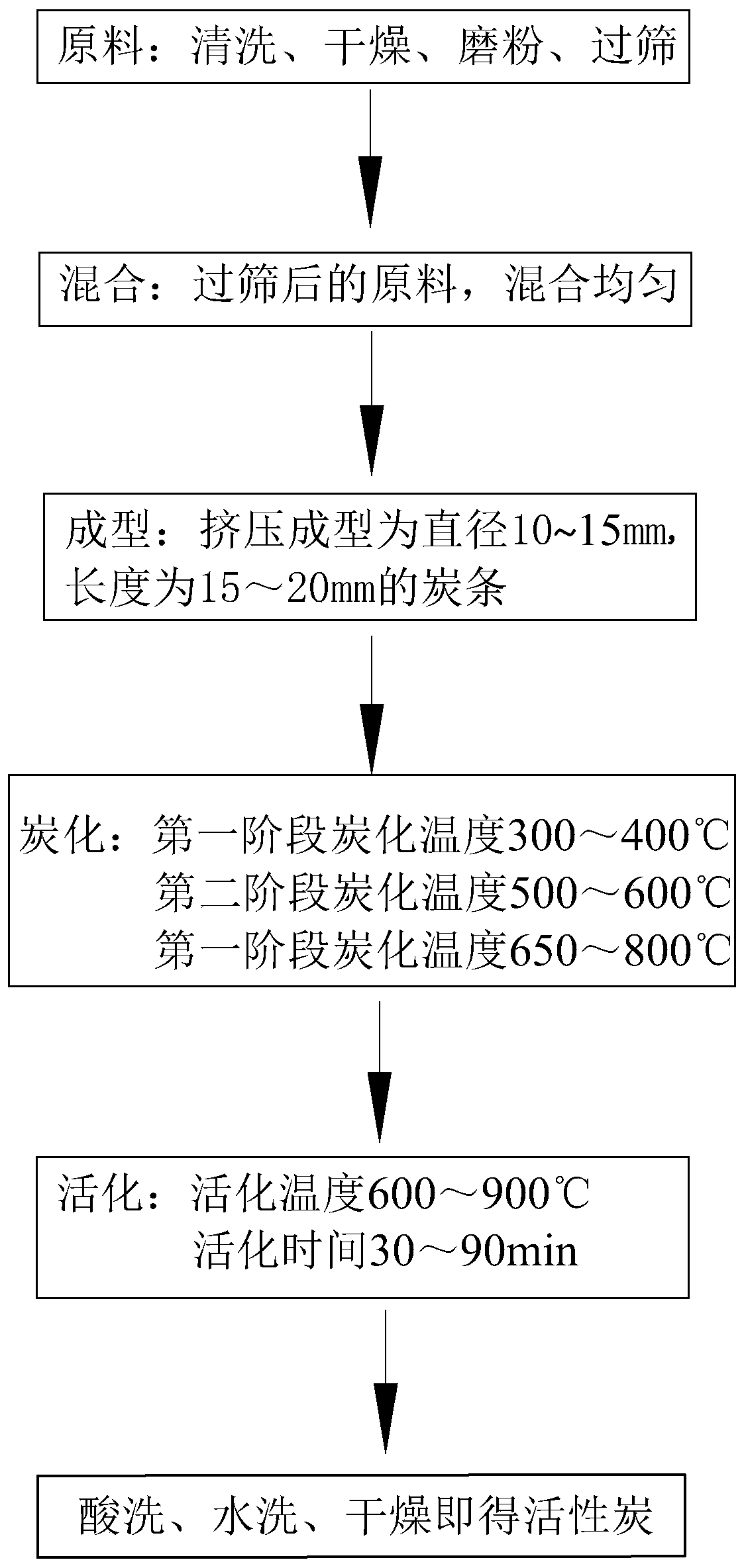

Method used

Image

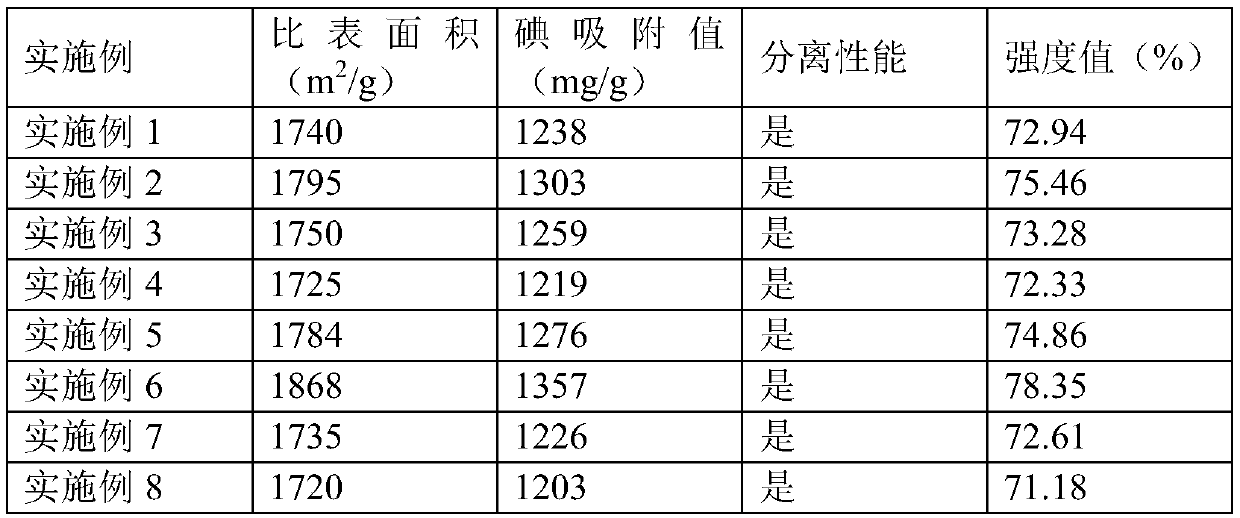

Examples

Embodiment 1

[0036] A preparation method for activated carbon, specifically comprising the steps of:

[0037] Step 1, the lignocellulose is cleaned, dried and pulverized and passed through a 60-mesh sieve for later use, and the pulverized lignocellulose is subjected to acidification treatment to obtain acidified biomass powder. Add hydrochloric acid with a mass fraction of 10wt% to the cellulose, stir well and react at 140°C for 2 hours, after natural cooling, filter and remove the filtrate, wash the filter residue with deionized water at least twice, dry the filter residue and grind it through a 60-mesh sieve , which is acidified biomass powder;

[0038] Step 2, the coal slime is subjected to flotation treatment until the ash content is not greater than 25%, and then dried, crushed, and passed through a 200-mesh sieve to obtain coal slime powder for subsequent use;

[0039] Step 3, according to the number of parts by mass, weigh 10 parts of wood powder, 10 parts of sepiolite, 30 parts of...

Embodiment 2

[0045] A preparation method for activated carbon, specifically comprising the steps of:

[0046] Step 1, the straw is washed, dried and crushed and passed through a 60-mesh sieve for later use, and the crushed straw is subjected to acidification treatment to obtain acidified biomass powder. The acidification method of the straw is: add 10 wt. % hydrochloric acid, stirred evenly and reacted at 180°C for 4 hours, after natural cooling, filtered to remove the filtrate, washed the filter residue with deionized water at least twice, dried the filter residue and ground it through a 60-mesh sieve to obtain acidified biomass powder;

[0047] Step 2, the coal slime is subjected to flotation treatment until the ash content is not greater than 25%, and then dried, crushed, and passed through a 200-mesh sieve to obtain coal slime powder for subsequent use;

[0048] Step 3, according to the number of parts by mass, weigh 15 parts of wood powder, 20 parts of montmorillonite, 40 parts of aci...

Embodiment 3

[0054] A preparation method for activated carbon, specifically comprising the steps of:

[0055] Step 1, the fruit shell is washed, dried and crushed and passed through a 60-mesh sieve for later use, and the crushed fruit shell is subjected to acidification treatment to obtain acidified biomass powder. The acidification method of the fruit shell is: adding Sulfuric acid with a mass fraction of 10wt%, stirred evenly and reacted at 200°C for 6 hours, after natural cooling, filtered to remove the filtrate, washed the filter residue with deionized water at least twice, dried the filter residue and ground it through a 60-mesh sieve, which is acidification biomass powder;

[0056] Step 2, the coal slime is subjected to flotation treatment until the ash content is not greater than 25%, and then dried, crushed, and passed through a 200-mesh sieve to obtain coal slime powder for subsequent use;

[0057] Step 3, weighing 13 parts of wood flour, 15 parts of illite, 35 parts of acidified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com