Method for lowering pH value of active calcium silicate

A technology of active calcium silicate and pH value, which is applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of reducing the pH value of highly alkaline active calcium silicate and high pH value of active calcium silicate, and achieves The effect of low production cost, improved utilization rate, and low energy and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

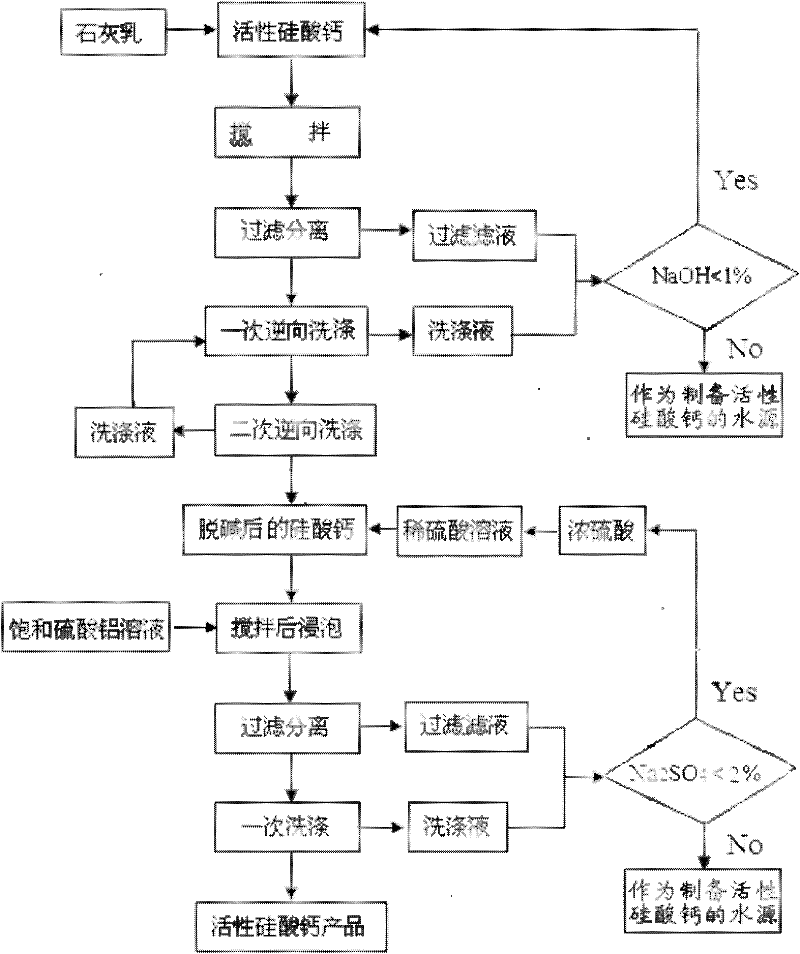

[0038] figure 1 It is a flowchart of the method for reducing the pH value of active calcium silicate provided by Example 1 of the present invention. The active calcium silicate to be treated in this embodiment is the active calcium silicate co-produced by extracting alumina from high-alumina fly ash. Specific steps are as follows:

[0039] (1) Na of the active calcium silicate to be treated is detected 2 O mass percentage content is 3.1%, and the mass percentage content of water is 50%, and pH value is 13.7;

[0040] (2) Preparation of milk of lime: CaO and water are mixed in a ratio of 1:4 by mass, and the stirring time is 1 hour, and then the slag removal process is carried out, and the impurities at the bottom are removed to obtain milk of lime; the slag removal process here is Refers to the slag removal treatment of lime milk: in the process of preparing lime milk by adding water to the quicklime, since only active CaO in quicklime can react with water to form lime milk...

Embodiment 2

[0047] (1) Na of the active calcium silicate to be treated is detected 2 O mass percentage content is 1.8%, and the mass percentage content of water is 65%, and untreated calcium silicate pH is 13.2;

[0048] (2) Preparation of milk of lime: CaO and water are mixed in a ratio of 1:4 by mass, the stirring time is 1 hour, and then slag removal is carried out to remove impurities at the bottom to obtain milk of lime with higher purity;

[0049] (3) Slowly add milk of lime and water to the active calcium silicate to be treated and stir evenly. The mass ratio of effective calcium in active calcium silicate to milk of lime is 33:1, the reaction temperature is 90°C, and the reaction time is 1.0h , after filtration and separation, two reverse washes were carried out, and the Na in the active calcium silicate 2 O content reduced to 0.42%;

[0050] (4) Prepare a sulfuric acid solution with a mass fraction of 2 / 1000. Under normal temperature conditions, add the active calcium silicate...

Embodiment 3

[0055] (1) Na of the active calcium silicate to be treated is detected 2 The mass percent content of O is 0.7%, the mass percent content of water is 68%, and the pH of the untreated calcium silicate is 12.8.

[0056] (2) Prepare a sulfuric acid solution with a mass fraction of 2 / 1000. Under normal temperature conditions, add the active calcium silicate in step (1) into the dilute sulfuric acid solution, soak for 30 minutes after fully stirring, and the mass ratio of active calcium silicate to pure sulfuric acid is 26:1;

[0057] (3) Add saturated aluminum sulfate solution to the active calcium silicate in step (2), soak for 20min after fully stirring, and the mass ratio of active calcium silicate to solid aluminum sulfate is 30:1;

[0058] (4) Filter the active calcium silicate in step (3), wash the filter cake once with clear water, the ratio of the clear water washing liquid to the dry basis of active calcium silicate is 3:1, and finally obtain the active calcium silicate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com