Graphene powder material with three-dimensional structure and optimized production method

A technology of graphene powder and production method, applied in the field of graphene, can solve the problems of difficulty in scale and industrialization, low specific surface area of graphene, and high production cost, and achieve easy scale and industrial production, high specific surface area and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

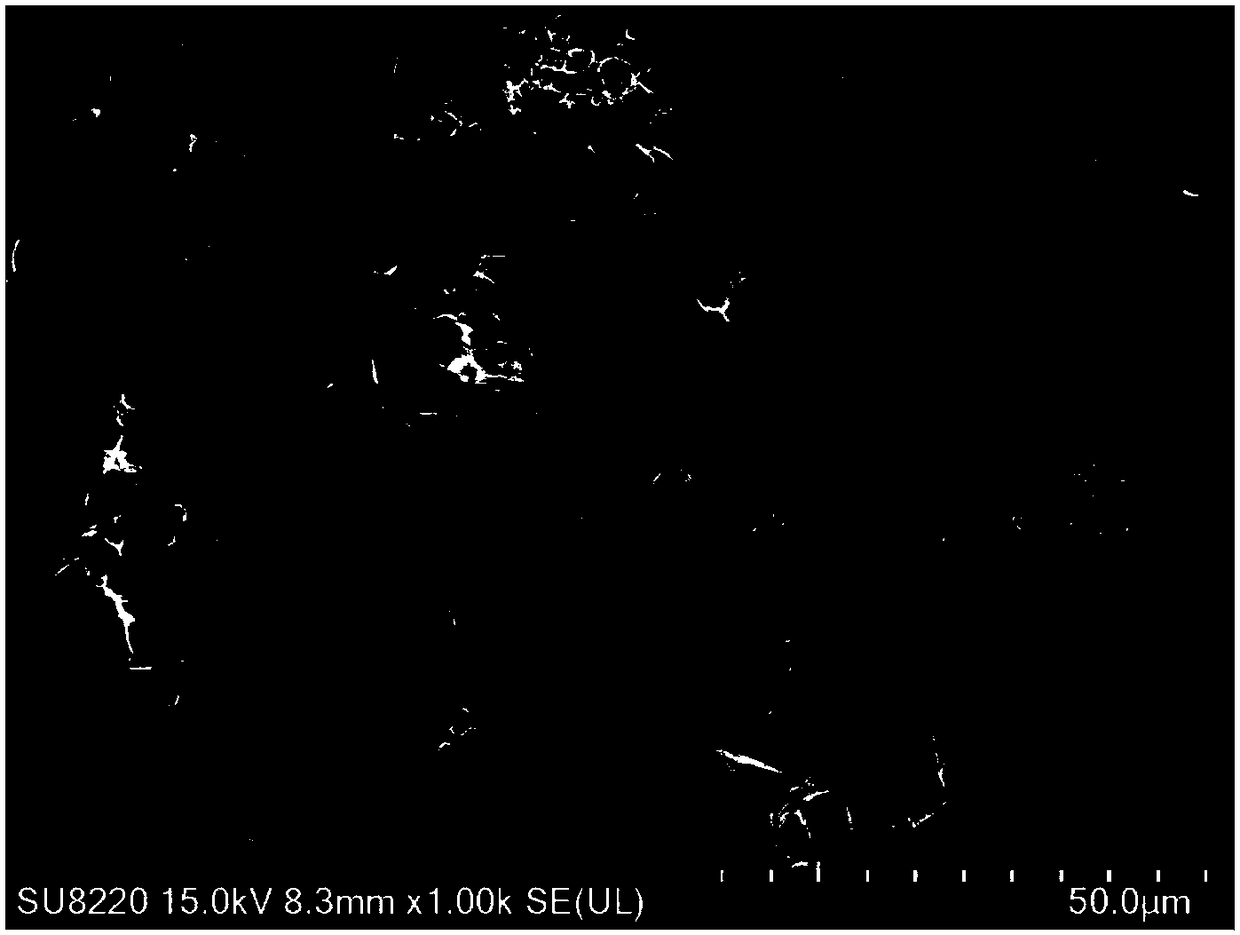

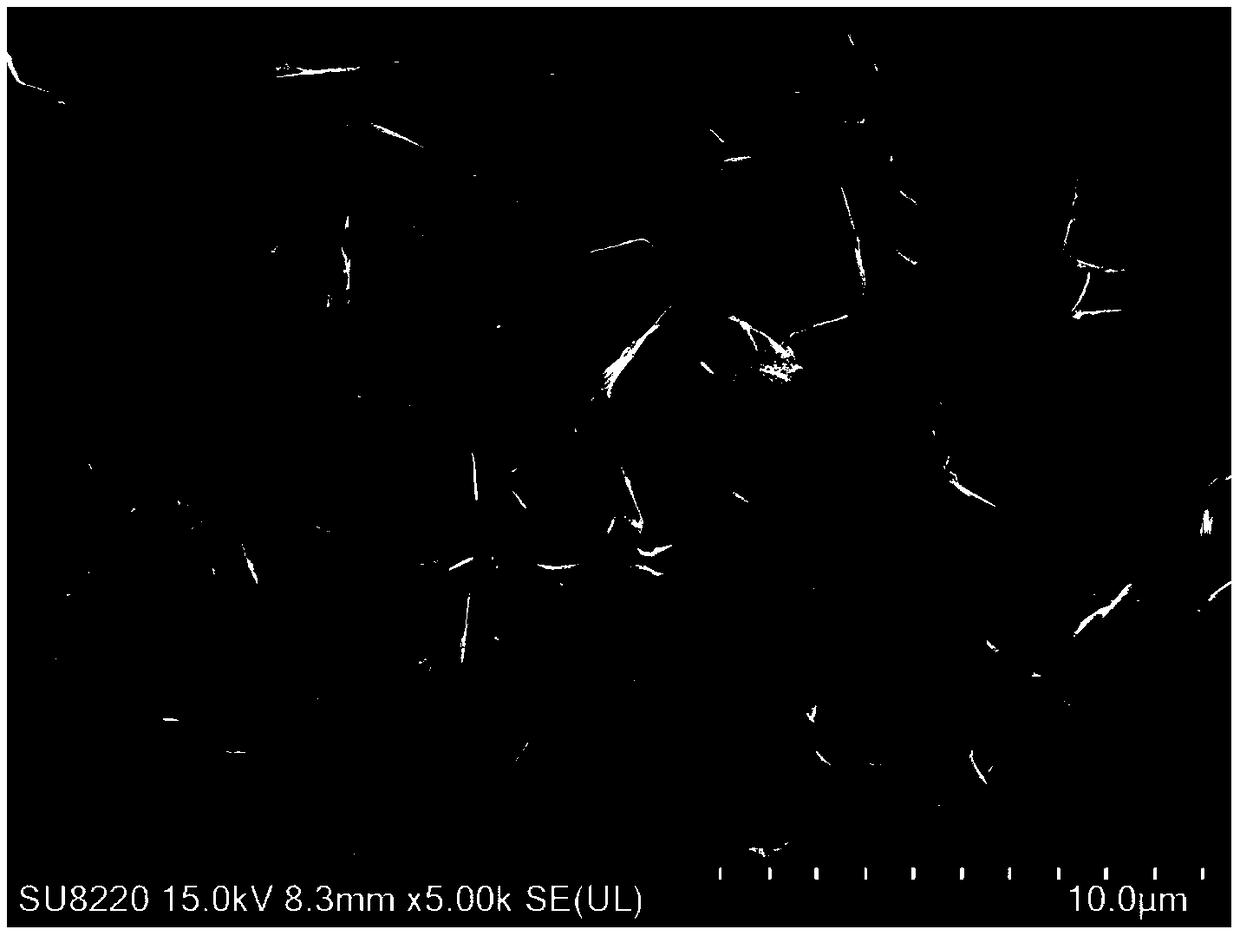

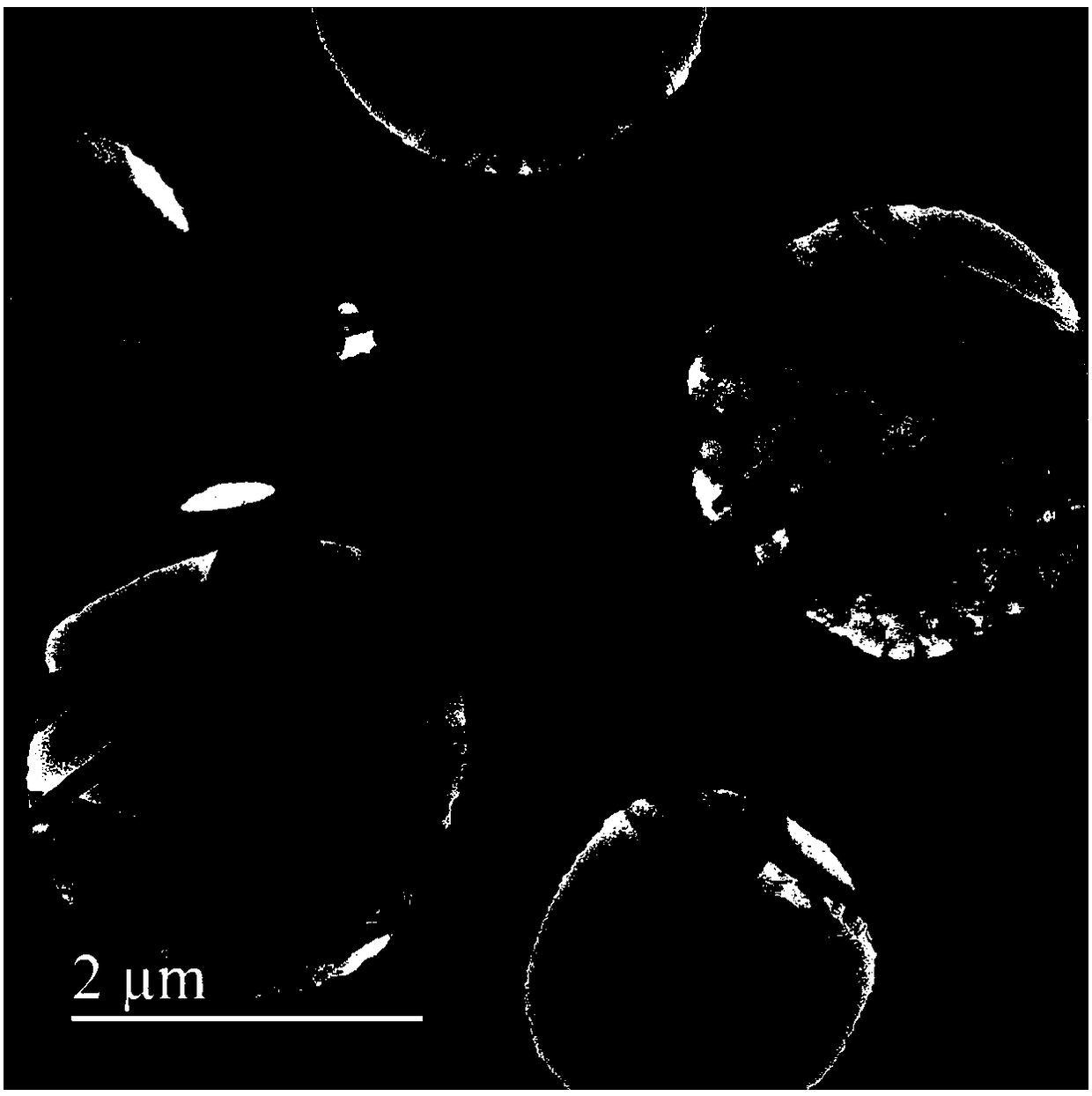

Image

Examples

Embodiment 1

[0027] (1) Immerse 10g of hydrogen-form (PKS-1) ion exchange resin into 100ml potassium hydroxide solution (5M concentration) for 10 hours and then clean it, then immerse the cleaned resin in 100ml hydrochloric acid solution (5M concentration) for 10 hours, then clean it to obtain Standby; then the nickel acetate of 0.08mol is dissolved in deionized water, and the nickel metal ion salt solution that forms concentration is 0.02mol / L adds the above-mentioned spare 10g hydrogen type (PKS-1) ion exchange resin, magnetic stirring is even, makes ion The exchange resin adsorbs metallic nickel, and then washes the ion-exchange resin after adsorbing metallic nickel with deionized water, adds 10 g of the resin obtained after cleaning into an aqueous potassium hydroxide solution containing 10 g of pore-forming agent potassium hydroxide, stirs and dries, and pulverizes , that is, the sensitization treatment is completed;

[0028] (2) keeping the raw material after the sensitization treatm...

Embodiment 2

[0033] (1) Immerse 10g of free amine type (PKS-3) ion exchange resin into 100ml potassium hydroxide solution (5M concentration) for 10 hours and then clean it, then immerse the cleaned resin in 100ml hydrochloric acid solution (5M concentration) for 10 hours, then clean it. Gained for subsequent use; then the sodium hexanitrocobaltate of 0.02mol is dissolved in deionized water to form a concentration of 2mol / L cobalt metal ion salt solution and add the above-mentioned standby 10g free amine type (PKS-3) ion exchange resin, Stir evenly by magnetic force to make the ion exchange resin adsorb metal cobalt, then clean the ion exchange resin after adsorbing metal cobalt with deionized water, add 10 g of the obtained resin after cleaning to an aqueous potassium hydroxide solution containing 5 g of pore-forming agent potassium hydroxide , stirred and dried, crushed, and the sensitization treatment is completed;

[0034] (2) keeping the raw material after the sensitization treatment i...

Embodiment 3

[0039](1) Immerse 10g of hydrogen-form (PKS-1) ion exchange resin into 100ml potassium hydroxide solution (5M concentration) for 10 hours and then clean it, then immerse the cleaned resin in 100ml hydrochloric acid solution (5M concentration) for 10 hours, then clean it to obtain Standby; Then the ferric sulfate of 4mol is dissolved in deionized water, forms the iron metal ion salt solution that concentration is 1mol / L and adds above-mentioned spare 10g hydrogen type (PKS-1) ion exchange resin, magnetic stirring is even, makes ion exchange resin Adsorb metallic iron, then wash the ion-exchange resin after adsorbing metallic iron with deionized water, add 10 g of the resin obtained after cleaning into an aqueous potassium hydroxide solution containing 2 g of pore-forming agent potassium hydroxide, stir and dry, and pulverize, namely Complete the sensitization treatment;

[0040] (2) keeping the raw material after the sensitization treatment in step (1) at a temperature of 90° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com