Physical testing method capable of directly observing internal deformation of rock mass model

A physical test and model technology, which is used in the preparation of test samples, measurement devices, and material analysis by optical means, can solve the problem that the internal deformation of the rock mass model cannot be directly observed, and achieves easy popularization, economical use, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

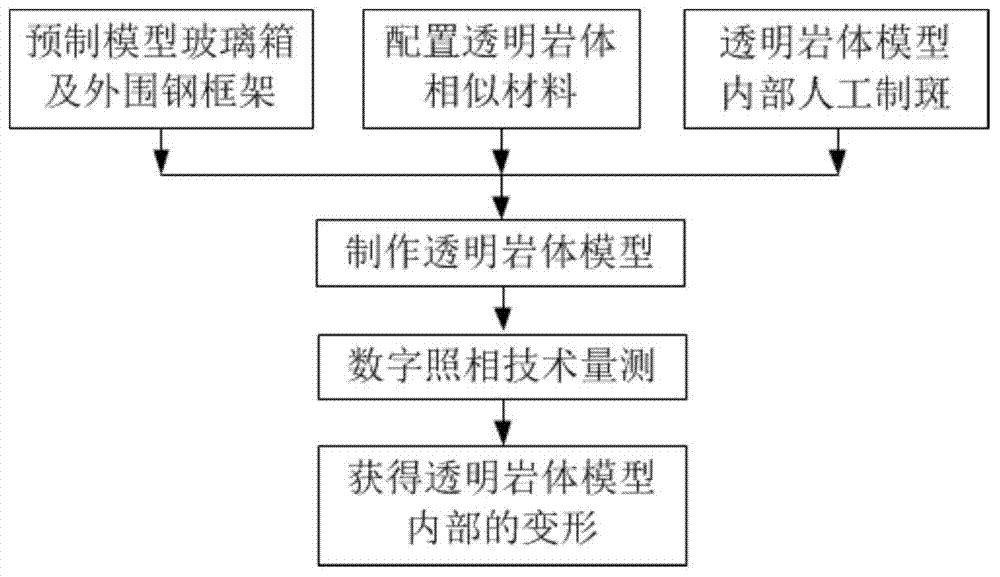

[0026] Embodiment 1: comprise the following steps:

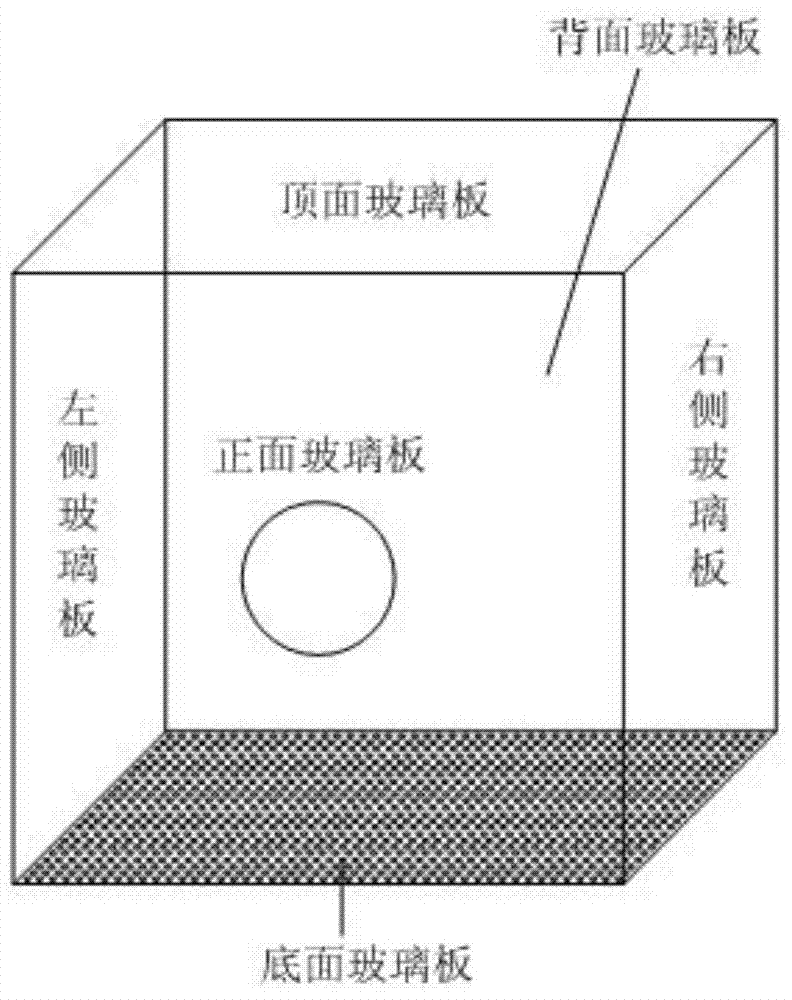

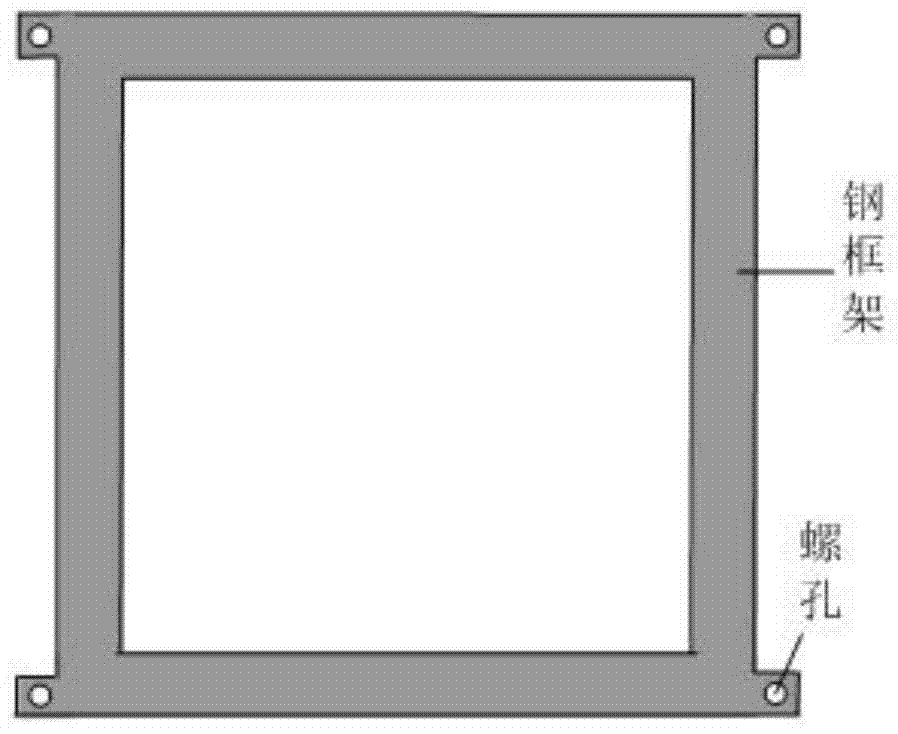

[0027] (a) Prefabricated rock mass model test device, including two structures of glass box and peripheral steel frame, wherein the glass box is composed of 6 plexiglass plates (attached figure 2 ), the bottom glass plate needs to be drilled with a number of small holes with an interval of 10mm and a diameter of 2mm, which are used for liquid discharge when similar materials in transparent rock mass are consolidated, and the front glass plate needs to be drilled with circular or Holes of other shapes are used to facilitate subsequent test excavation; the purpose of the peripheral steel frame is to ensure that the plexiglass box will not be deformed under the test load, and it is composed of 4 hollow cutting steel plates (attached image 3 ) and 8 screw rods;

[0028] (b) Use colored paint spray cans to spray paint on 300-mesh transparent silicon powder particles to form colored silicon powder particles of various single co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com