Scanning electron microscope characterization method for graphene dispersibility in graphene polymer composite material

An electron microscope and alkene polymer technology, applied in the field of scanning electron microscopy, can solve the problems of difficult graphene position, uneven fracture, and dimples affecting the test effect, etc., achieve small stress, high sample flatness, and facilitate shape analysis The effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, graphene / polyimide is used as the composite material for testing; the mass percentage of graphene in the composite material is 0.5%.

[0043] Characterize the dispersion of graphene in the composite material to study whether graphene forms a conductive network in the composite material, which plays an important role in strengthening the conductive properties of the composite material.

[0044] The specific characterization method is as follows:

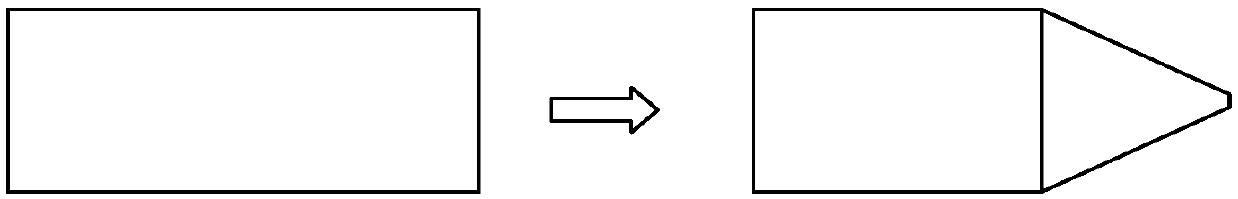

[0045](1) After preprocessing, the composite material is trimmed into a rectangular strip sample with a length of 20mm, and the radial dimension of the end face is 5mm×5mm; figure 1 As shown, use a blade to further trim one end of the sample along the length direction so that it is in the shape of a truncated cone, and the radial dimension of the tip surface is 1.6mm×1mm;

[0046] (2) Fix the tip of the sample upwards on the sample stage of a mechanical pusher ultramicrotome equipped with a microscope; adju...

Embodiment 2

[0056] In this embodiment, the composite material is exactly the same as that in Embodiment 1. Characterize the dispersion of graphene in the composite material to study whether graphene forms a conductive network in the composite material, which plays an important role in strengthening the conductive properties of the composite material.

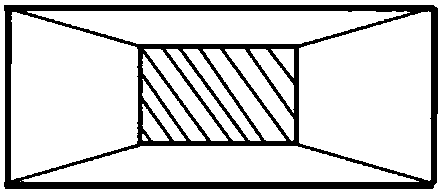

[0057] The specific characterization method is basically the same as the characterization method of Example 1, except that in step (2), such as image 3 As shown, the tip surface of the sample is finally trimmed into a trapezoid with a lower base of 0.6 mm, an upper base of 0.4 mm, and a height of 0.3 mm.

[0058] SEM results were similar to Figure 5 As shown, it can be seen that the scanning electron microscope image is clearly visible, and the dispersion of graphene in the polyimide material can be seen intuitively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com