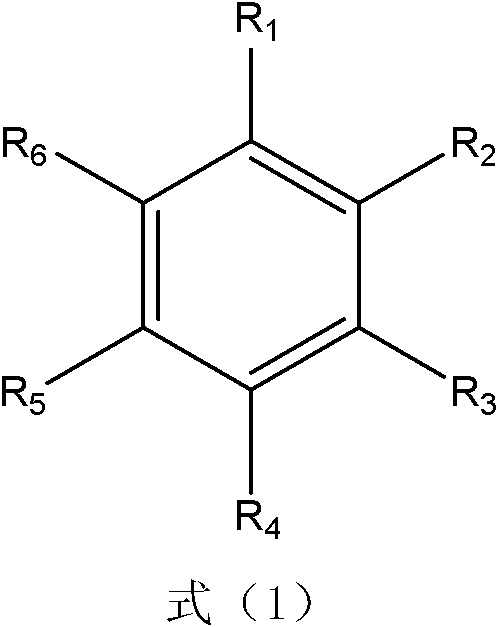

Method for preparing benzaldehyde or substituted benzaldehyde by catalytically oxidizing methylbenzene or substituted methylbenzene

A technology of catalytic oxidation and benzaldehyde, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as difficulty in realizing industrial production, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

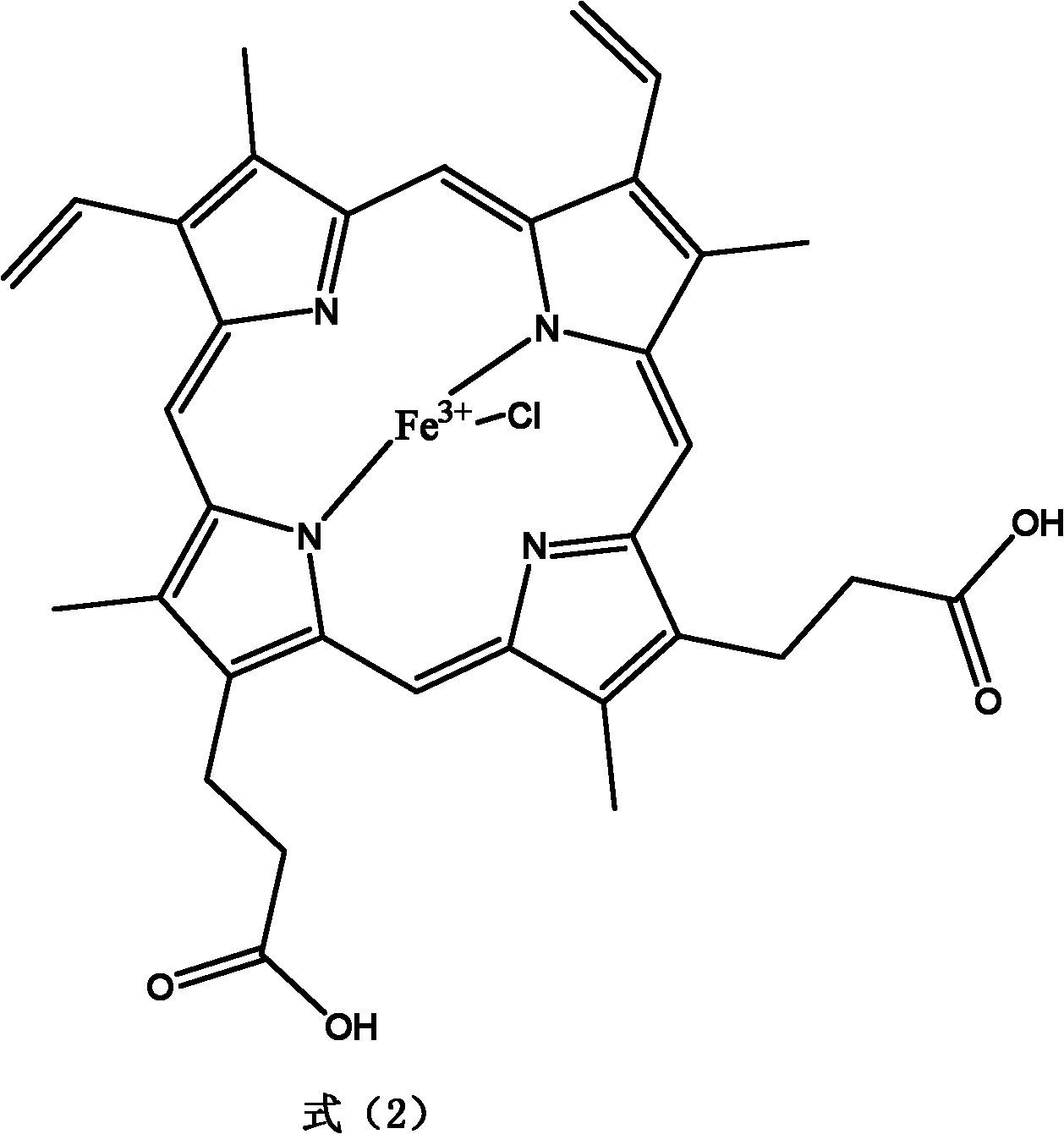

Method used

Image

Examples

Embodiment 1

[0041] Add 300 g of toluene and 5 mg of hemin into a 1-liter reactor; cover and seal the reaction system, and replace the air in the reactor with pure nitrogen for 2-3 times. The control temperature is 140°C and the pressure is about 2Mpa. The appropriate amount of air is added, and the reaction timer is started. After maintaining an appropriate temperature for 1 hour, stop the reaction. The conversion rate of toluene is 6%, the selectivity of benzaldehyde is 45%, the selectivity of benzyl alcohol is 33% and the selectivity of benzoic acid is 18%.

Embodiment 2

[0043] Add 300g of toluene and 100mg of hemin into a 1-liter reaction kettle; cover and seal the reaction system, replace the air in the kettle with pure nitrogen 2-3 times, control the temperature at 160°C, and the pressure at about 1.5Mpa. An appropriate amount of oxygen was added, and the reaction timer was started. After maintaining an appropriate temperature for 2 hours, stop the reaction. The conversion rate of toluene is 19%, the selectivity of benzaldehyde is 41%, the selectivity of benzyl alcohol is 35% and the selectivity of benzoic acid is 17%.

Embodiment 3

[0045] Add 300g of toluene and 150mg of hemin into a 1-liter reaction kettle; cover and seal the reaction system, replace the air in the kettle with pure nitrogen 2-3 times, control the temperature at 200°C, and the pressure at about 1.4Mpa. An appropriate amount of oxygen was added, and the reaction timer was started. After maintaining an appropriate temperature for 1 hour, stop the reaction. The conversion rate of toluene is 29%, the selectivity of benzaldehyde is 25%, the selectivity of benzyl alcohol is 31% and the selectivity of benzoic acid is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com