Lead sulfate-graphene composite electrode material and lead-acid battery negative electrode lead paste containing same

A graphene composite and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of short life, poor negative electrode high-rate discharge cycle performance, etc., achieve good retention rate, good conductivity, and reduce sulfate. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

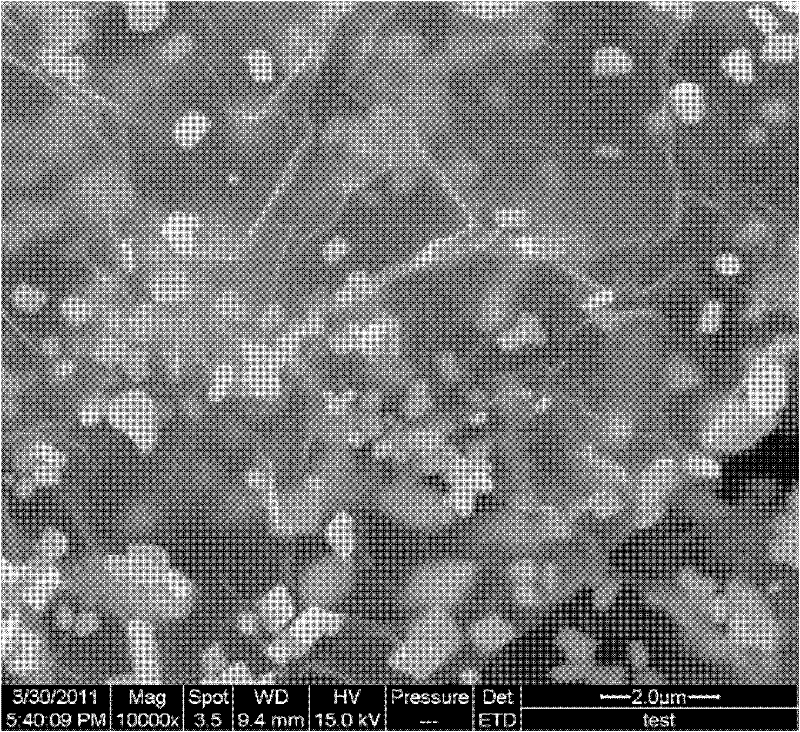

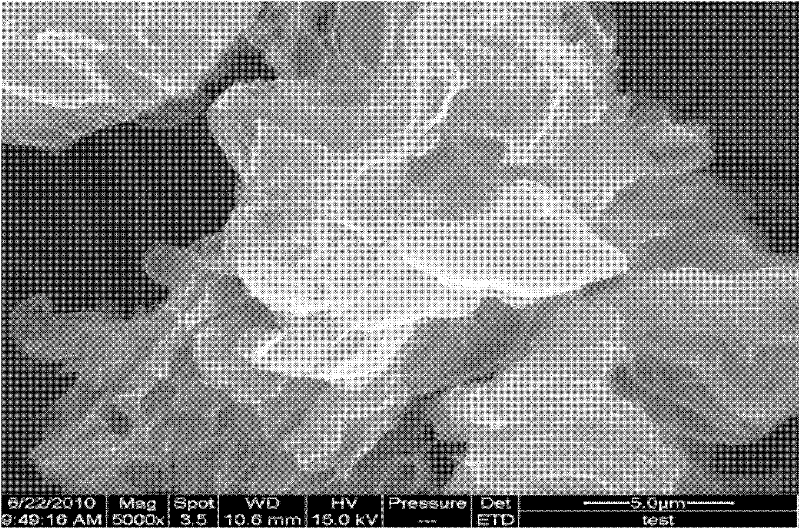

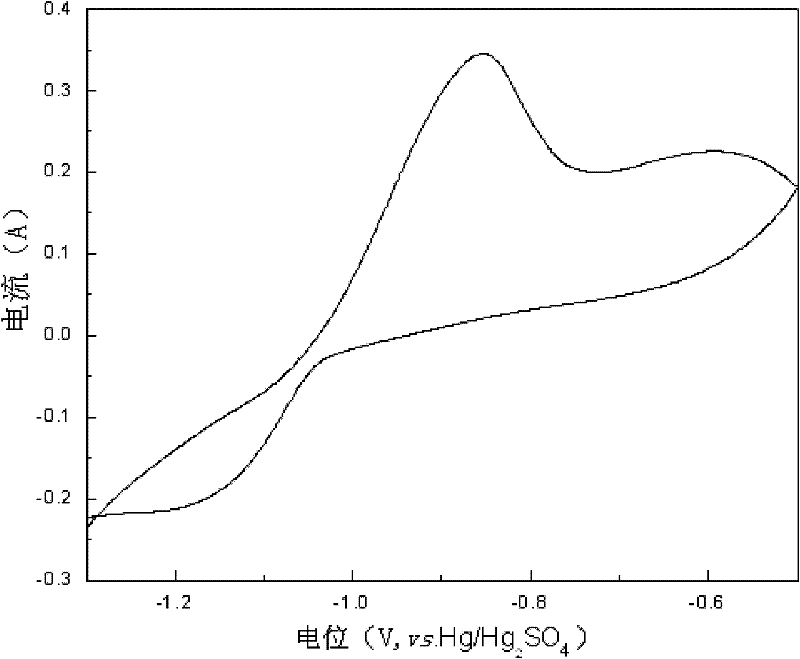

[0018] Specific embodiment 1: This embodiment is a lead sulfate-graphene composite electrode material, which is lead sulfate supported on graphene, and the mass ratio of lead sulfate to graphene is 0.1-10:1.

[0019] In this embodiment, the graphene is a commercially available product or is prepared according to an existing public preparation method.

[0020] The preparation method of the lead sulfate-graphene composite electrode material of this embodiment is as follows: under the conditions of ultrasonic stirring at 25-70°C and a frequency of 10-30KHz, the lead acetate solution is added to the graphene suspension and ultrasonically vibrated for 30- 60min to obtain the mixed solution; while stirring, add sulfuric acid solution dropwise to the mixed solution. After the addition is completed, continue to stir for 30-60 minutes, filter to obtain the solid, and then dry the solid at 40-80℃ for 3-6h, The lead sulfate-graphene composite electrode material is obtained, wherein the ratio ...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and the first embodiment is that the mass ratio of lead sulfate to graphene is 0.5-8:1. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: This embodiment is different from specific embodiment one in that the mass ratio of lead sulfate to graphene is 0.8-6:1. Other parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com