Lithium-rich manganese-based power battery and manufacturing method thereof

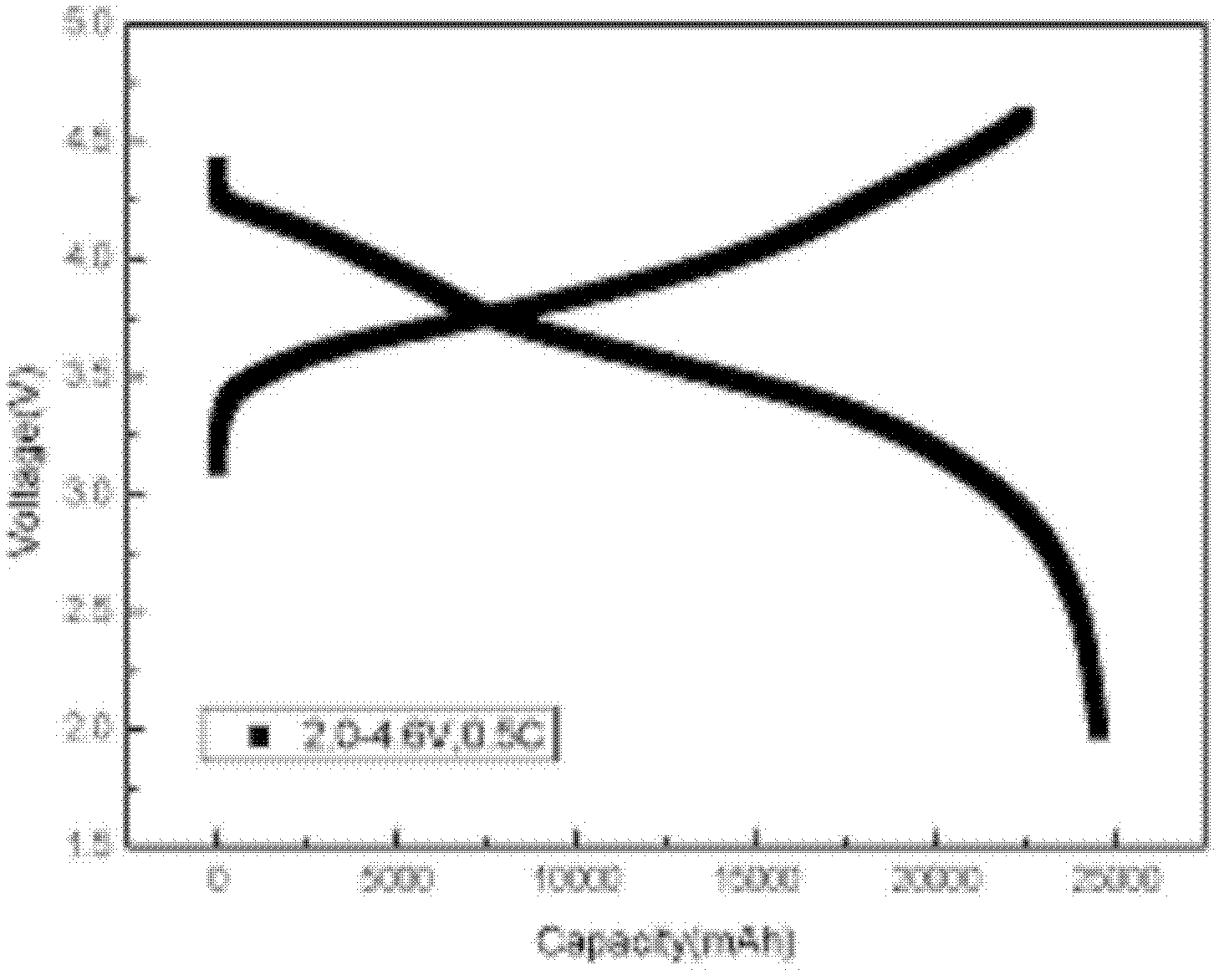

A lithium-rich manganese-based, power battery technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of low voltage, low compaction density, and low battery capacity of nickel-cobalt lithium manganese oxide platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

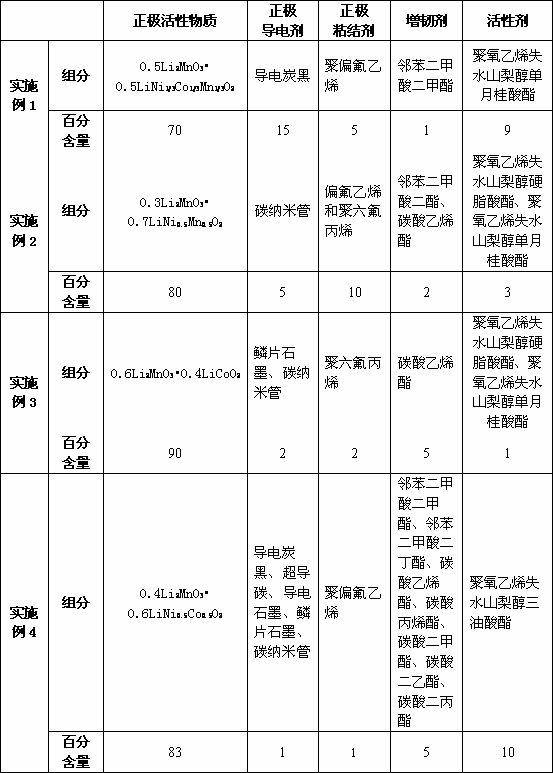

Embodiment 1

[0037] Dissolve the positive electrode material in N-methylpyrrolidone amine, the weight ratio of the positive electrode material to N-methylpyrrolidone amine is 1:1, and the components of the positive electrode material are shown in Table 1. Stir evenly and coat on a surface with a thickness of 15 μm On the aluminum foil, after drying at 140 ° C, it is rolled to obtain a thickness of 200 μm and a compacted density of 2.8 g / cm 3 Dissolve the negative electrode material in water, the weight ratio of the negative electrode material to water is 1:1.2, each component of the negative electrode material is as shown in Table 2, after stirring evenly, coat it on a copper foil with a thickness of 10 μm, at 120 After drying at ℃, roll pressing to obtain a thickness of 80 μm and a compacted density of 1.8 g / cm 3After cutting the obtained positive and negative electrodes, stack them in order according to the positive electrode, diaphragm and negative electrode, and use the laminated struc...

Embodiment 2

[0043] The positive electrode material is dissolved in N, N-dimethylformamide, the weight ratio of the positive electrode material to N, N-dimethylformamide is 1: 1.5, the components of the positive electrode material are shown in Table 1, after stirring Coated on aluminum foil with a thickness of 17μm, dried at 145°C and rolled to obtain a thickness of 150μm and a compacted density of 3.1g / cm 3 Dissolve the negative electrode material in water, the weight ratio of the negative electrode material to water is 1:1, the components of the negative electrode material are shown in Table 2, after stirring evenly, coat it on a copper foil with a thickness of 12 μm, and heat it at 125°C After drying, roll pressing to obtain a thickness of 130 μm and a compacted density of 1.3 g / cm 3 After cutting the obtained positive and negative electrodes, stack them in order according to the positive electrode, diaphragm and negative electrode, and use the laminated structure to make a cell; weld t...

Embodiment 3

[0046] The positive electrode material is dissolved in N-methylpyrrolidone and N, N-dimethylformamide, the weight ratio of the positive electrode material to N-methylpyrrolidone and N, N-dimethylformamide is 1:1.2, each positive electrode material The components are shown in Table 1. Stir evenly and coat on an aluminum foil with a thickness of 20 μm. After drying at 150 ° C, it is rolled to obtain a thickness of 250 μm and a compacted density of 2.7 g / cm 3 Dissolve the negative electrode material in water, the weight ratio of the negative electrode material to water is 1:1.5, each component of the negative electrode material is shown in Table 2, after stirring evenly, coat it on a copper foil with a thickness of 10 μm, at 130 After drying at ℃, roll pressing to obtain a thickness of 130 μm and a compacted density of 1.5 g / cm 3 After cutting the obtained positive and negative electrodes, they are stacked in sequence according to the positive electrode, separator and negative el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com