Preparation method of mesoporous carbon nanosheet and application of mesoporous carbon nanosheet as electrode material of super capacitor

A technology of nanosheets and mesoporous carbon, which is applied in the direction of hybrid capacitor electrodes, capacitors, electrolytic capacitors, etc., can solve the problems of reducing the specific surface area of graphene and ion transmission speed, etc., to achieve the advantages of transmission and diffusion, large specific capacity, and improved Effect of specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

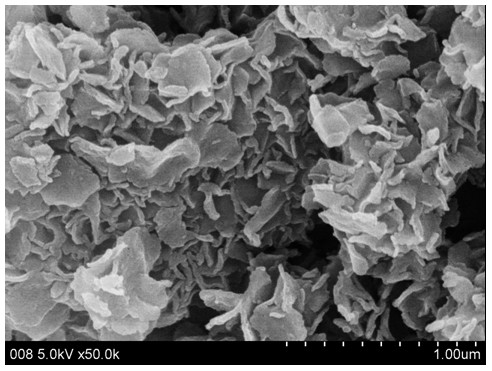

[0026] Dissolve 0.4g P123 in 400ml buffer solution containing 0.5g Tris, then ultrasonically disperse 0.4g magnesium oxide nanoflakes in the above solution, after cooling to room temperature, add 0.8g dopamine under stirring, and stir the reaction in air at 25°C 5h. Filtrate and wash the polydopamine / magnesium oxide composite, raise the temperature to 350°C at a rate of 1°C / min in an argon atmosphere, keep the temperature for 2 hours, and then raise the temperature to 850°C at a rate of 5°C / min for further carbonization After 4 hours, the template was finally removed in excess acid solution to obtain two-dimensional mesoporous carbon nanosheets. The scanning electron microscope photograph of the product is as figure 1 shown.

Embodiment 2

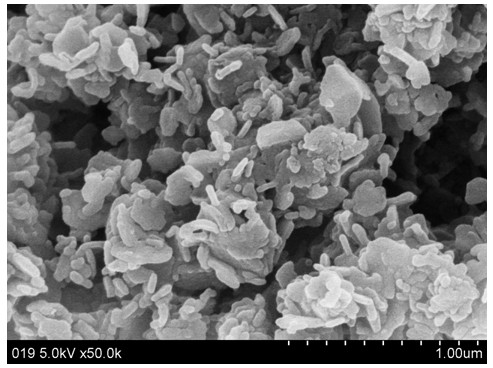

[0028] Dissolve 0.4g P123 in 400ml buffer solution containing 0.5g Tris, then ultrasonically disperse 0.4g magnesium oxide nanosheets in the above solution, cool to room temperature, add 1.6g dopamine under stirring, 25°C (10-40°C) The reaction was stirred in air for 5h. Filtrate and wash the polydopamine / magnesium oxide complex obtained, in an argon atmosphere at a heating rate of 1 °C / min to 350 °C (300~350 °C is acceptable), keep the temperature for 2 hours, and then at a rate of 5 °C / min The temperature was raised to 850°C (800-900°C is acceptable), further carbonized for 4 hours, and finally the template was removed in excess acid solution to obtain two-dimensional mesoporous carbon nanosheets. The scanning electron microscope photograph of the product is as figure 2 shown.

Embodiment 3

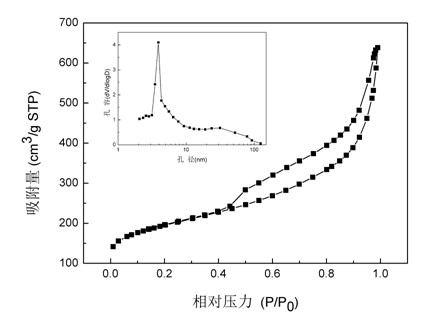

[0029] Example 3 Characterization of Mesoporous Carbon Nanosheets

[0030] Nitrogen adsorption-desorption analyzer (Micromeritics ASAP 2020) was used to characterize the specific surface area and pore size distribution of the mesoporous carbon nanosheets prepared in the above example 1, the results are as follows image 3 and shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com