Boiler heating intelligent control system and method based on internet of things

An intelligent control system and boiler control technology, applied in the field of boiler heating, can solve the problems of the boiler room being unable to communicate operating status information, unable to achieve real-time and stable control of water temperature, and unable to optimize control of frequency conversion devices, etc. Optimize the speed, solve the effect of poor accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

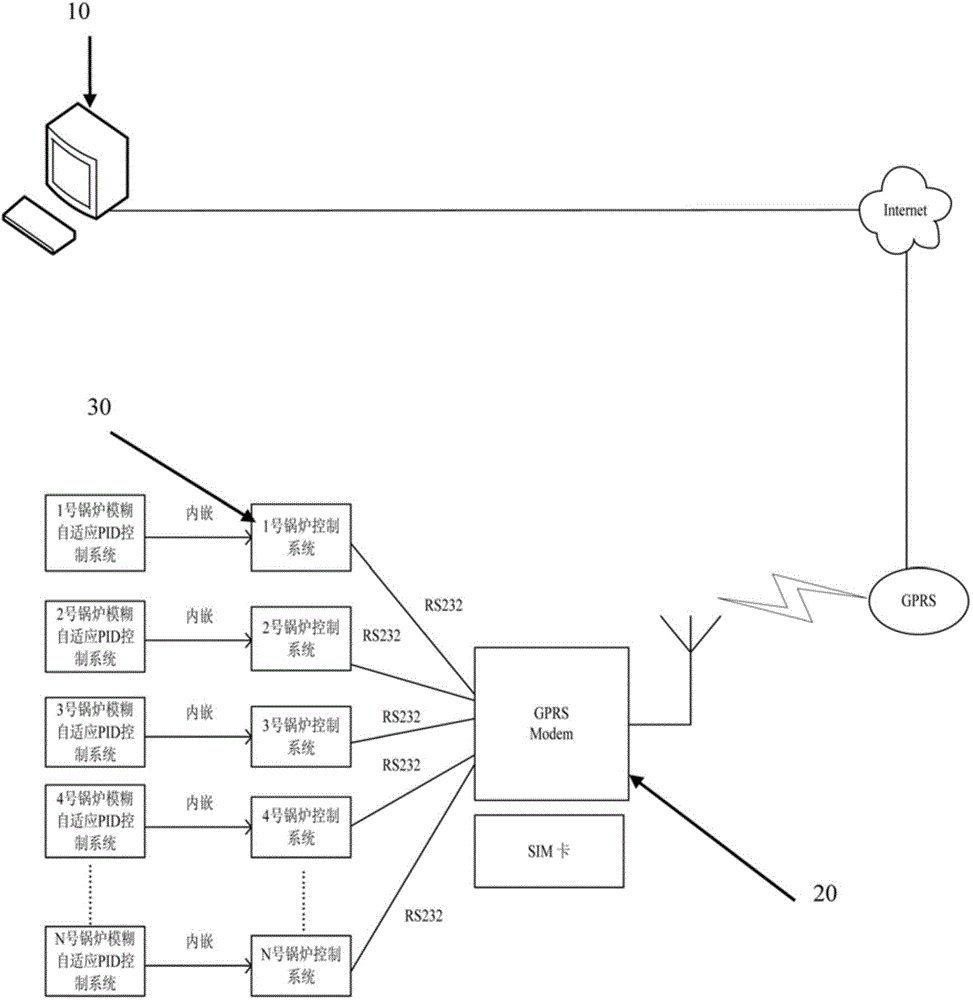

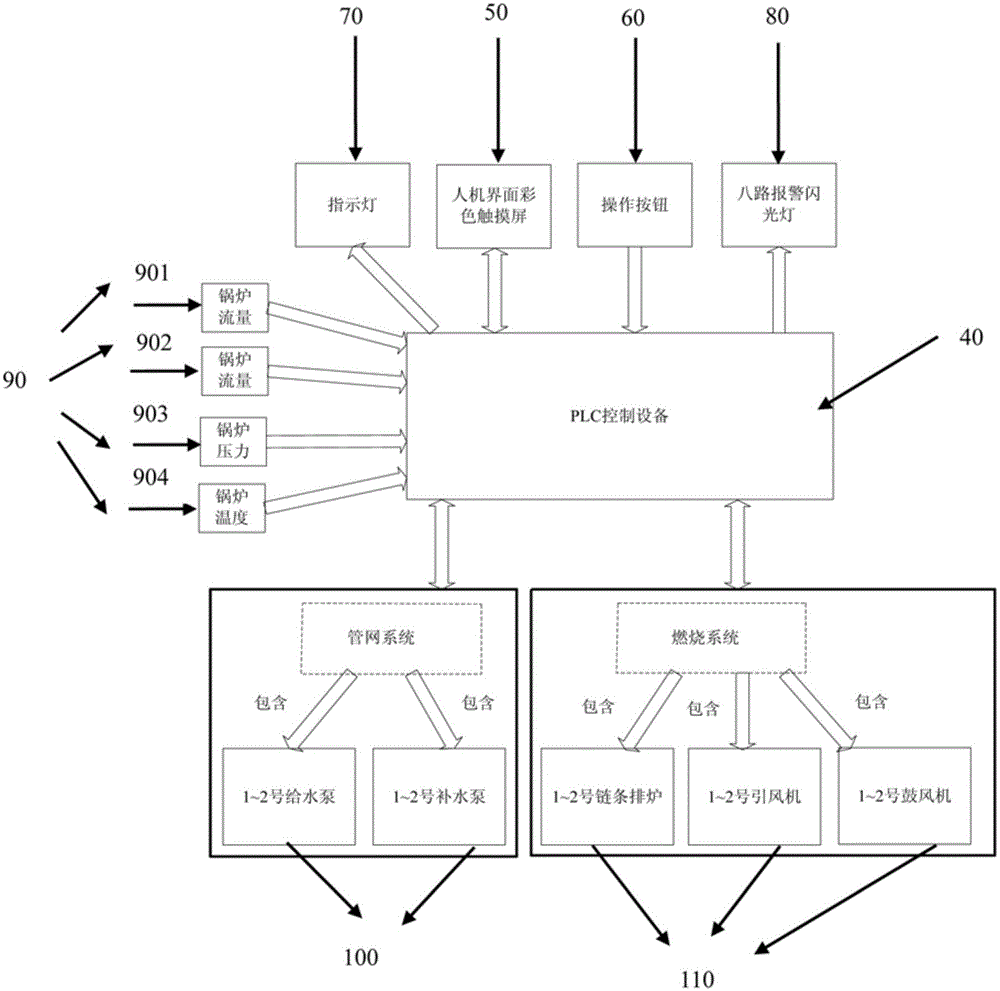

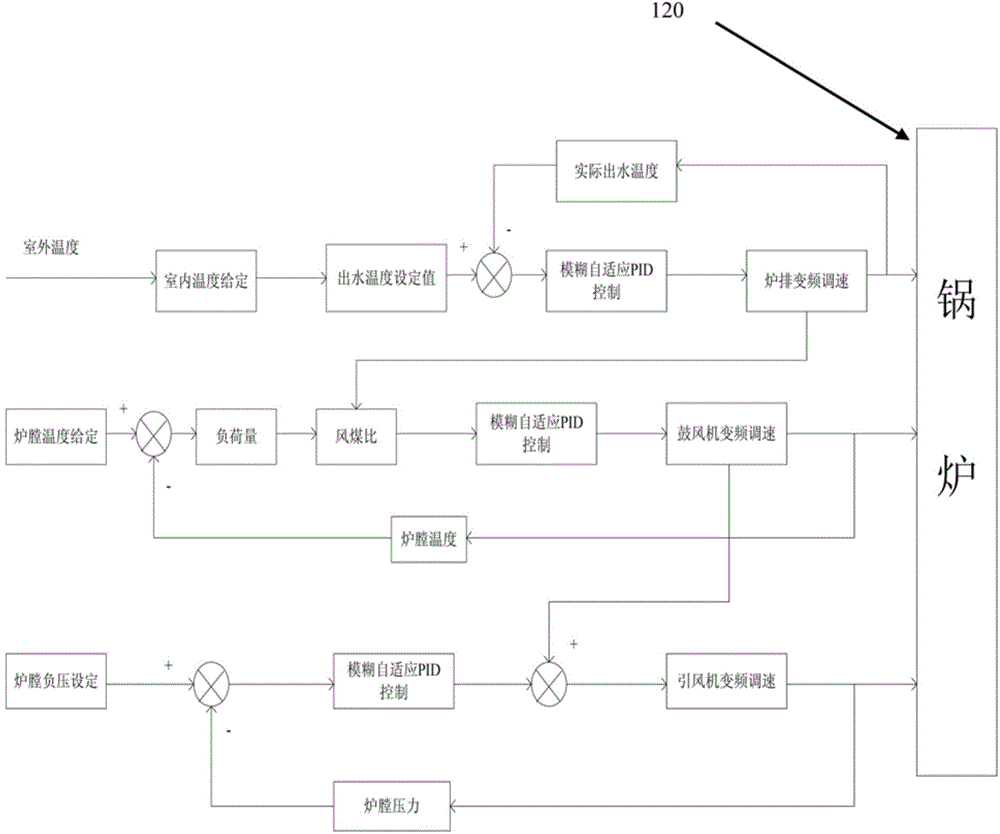

[0034] The boiler heating intelligent control system based on the Internet of Things not only combines the advanced Internet of Things mobile terminal with PLC industrial automation, but also can introduce fuzzy adaptive PID control according to the actual working conditions such as outdoor temperature and return water temperature to control the speed of the grate. , Feed water pump, make-up water pump speed, blower, induced draft fan speed to carry out optimal frequency conversion speed regulation, so as to realize the automatic, efficient, stable and reliable operation of the heating system. Simply modify the original boiler heating system, add some modules, and add a PC industrial computer as a remote monitoring device to form the control system. The cost is low, the construction is convenient, and the control effect is good. It is an ideal boiler control system. device. The present invention adds a fuzzy self-adaptive PID controller such as Image 6 As shown, it can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com