Thermal power plant boiler NOx emission control method under variable-load working conditions

A boiler control and thermal power plant technology, which is applied in the field of NOx emission control of thermal power plant boilers under variable load conditions, can solve the problems that NOx emission control is still in its infancy and the difficulty of predicting and controlling NOx emissions of boilers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] Taking the power generation process of a thermal power plant as an example, the NOx emission control method of a thermal power plant boiler under variable load conditions of the present invention is implemented, and the data are shown in Table 1.

[0050] Table 1 data situation

[0051] predictive model input dimension output dimension Number of historical data samples number of forecast samples boiler load 9 1 1000 590 NOx emissions 16 1 1000 590

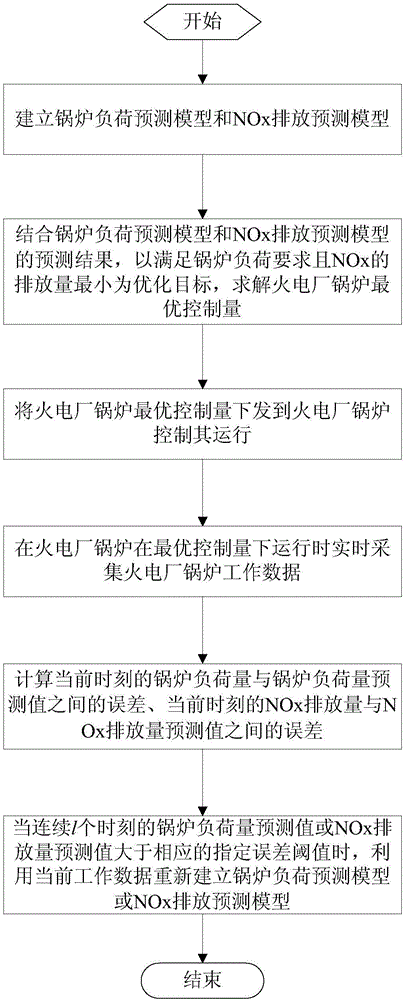

[0052] This embodiment provides a figure 1 The NOx emission control methods for thermal power plant boilers under variable load conditions include:

[0053] Step 1: Establish boiler load prediction model and NOx emission prediction model;

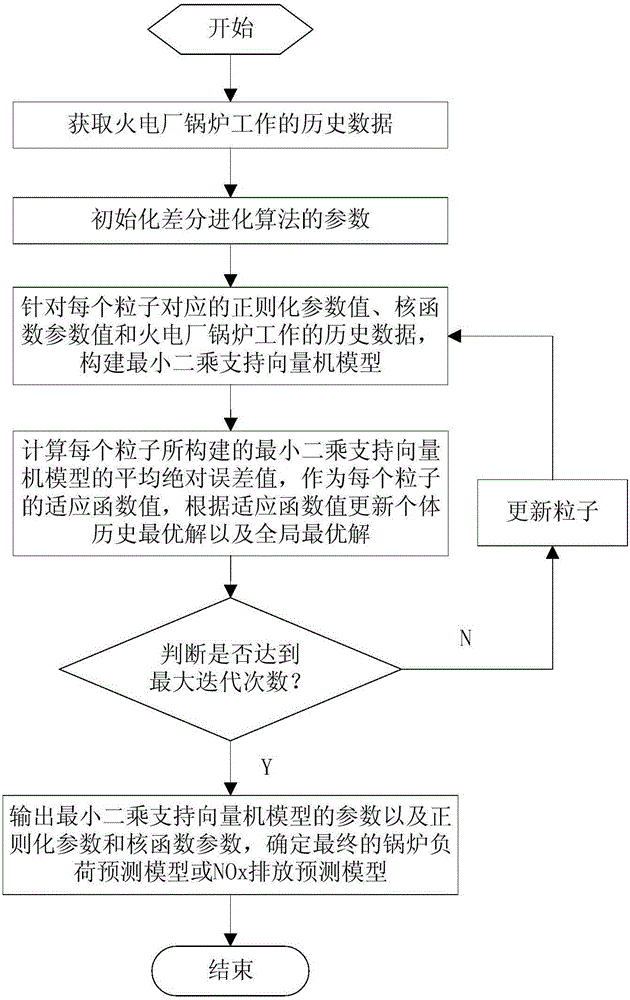

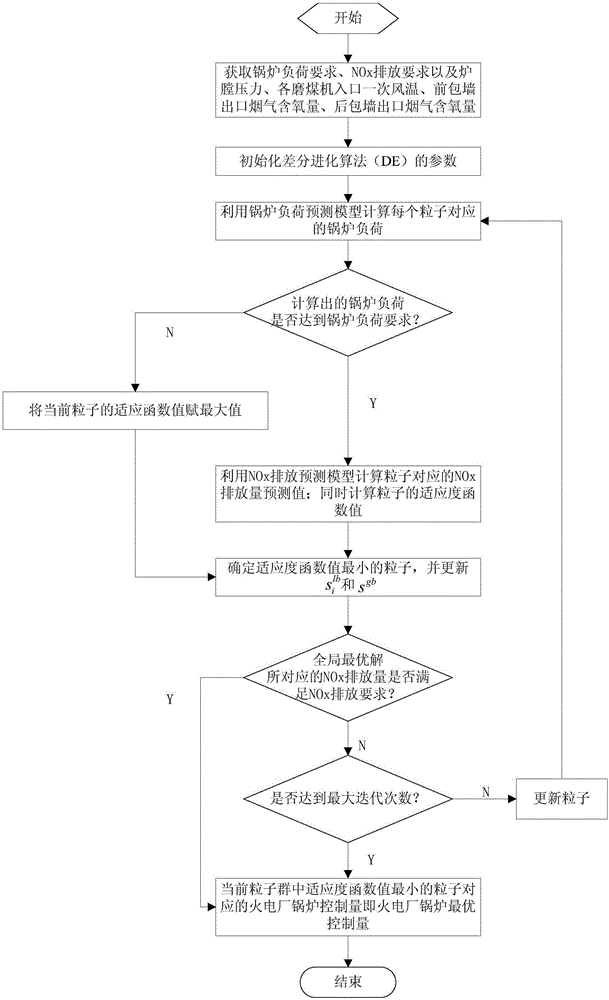

[0054] The input volume of the boiler load prediction model is the total fuel volume of the boiler, the main fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com