Startup boiler control system

A control system, a technology for starting boilers, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of limited number of I/O channels, increased operation capacity, inconvenient maintenance, etc., to improve the degree of centralized control operation , the effect of improving the degree of automation and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

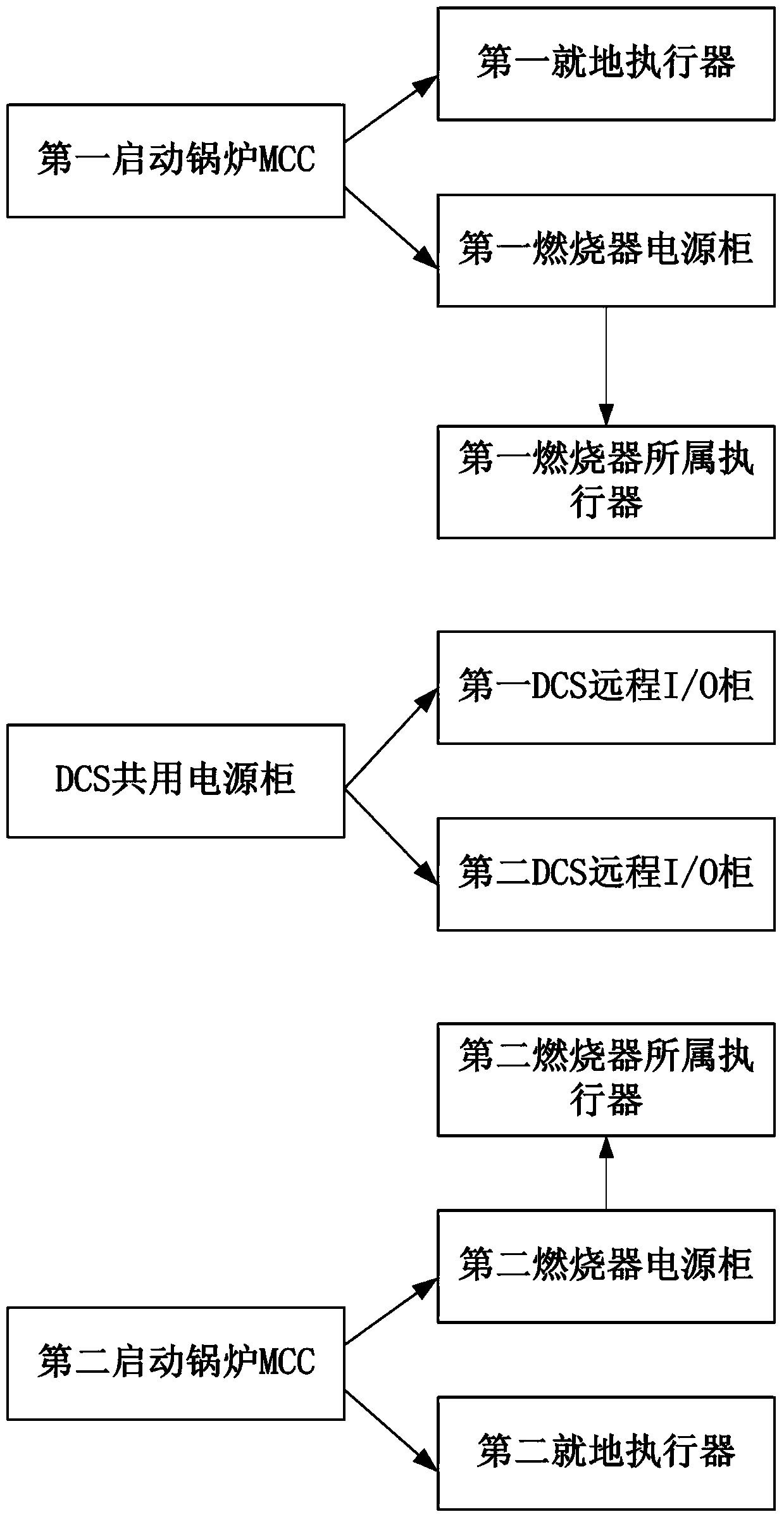

[0040] Such as figure 2 As shown, the start-up boiler control system of the present invention includes a power supply system, and the power supply system includes the first start-up boiler MCC, the second start-up boiler MCC and the DCS public power supply cabinet, and the local actuators and first burners belonging to the first start-up boiler Power supply cabinet, actuator of the first burner, remote I / O cabinet of the first DCS, local actuator of the second start-up boiler, power cabinet of the second burner, actuator of the second burner and remote I / O cabinet of the second DCS / O cabinet; the first start-up boiler MCC respectively supplies power to the local actuator belonging to the first start-up boiler and the first burner power supply cabinet; the second start-up boiler MCC respectively supplies power to the local actuator and the second burner belonging to the second start-up boiler The power supply cabinet supplies power; the DCS public power supply cabinet supplie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com