Circulating fluidized bed boiler combusting low calorific value gas fuel

A low calorific value gas and circulating fluidized bed technology, which is applied in the direction of fuel burning in a molten state, fluidized bed combustion equipment, combustion types, etc., can solve problems such as immature products, and achieve environmental protection emissions, stable combustion, and The effect of meeting emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments.

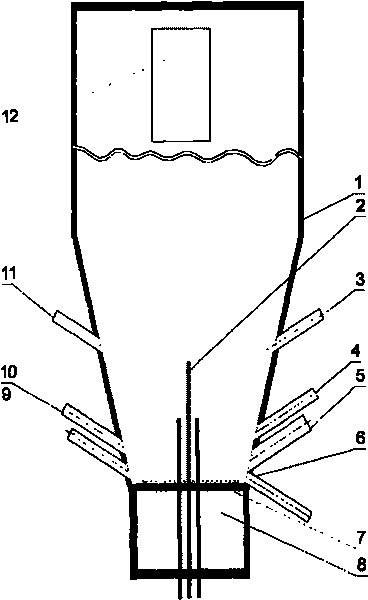

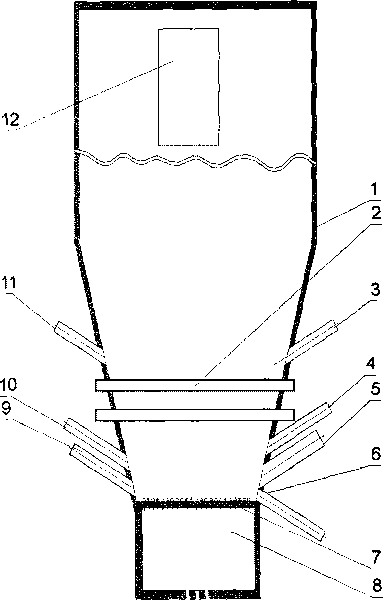

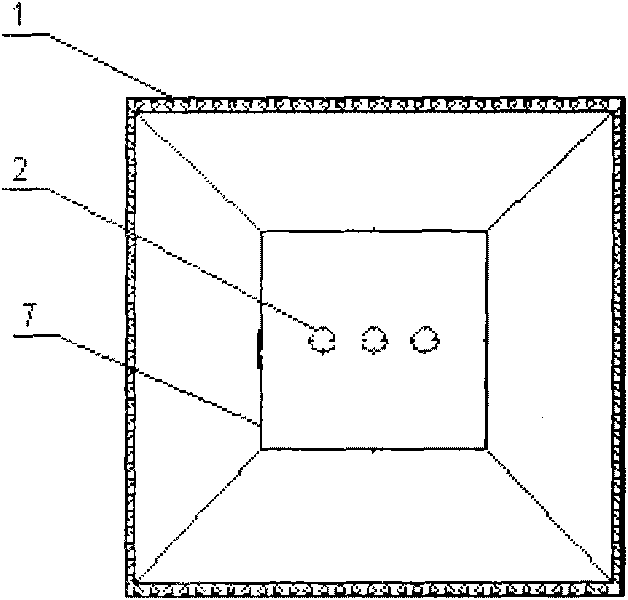

[0021] see figure 1 , figure 2 , a circulating fluidized bed boiler that burns low-calorific-value gaseous fuels, including a furnace wall 1, the cavity formed by the furnace wall 1 is the furnace, an air distribution plate 7 is arranged at the bottom of the furnace, and an air chamber 8 is arranged below the air distribution plate 7, Furnace smokestack 12 is arranged on the upper part of the furnace, and limestone feeding pipe 4, return pipe 5, slag discharge pipe 6, gas feeding pipe 9 outside the furnace, auxiliary fuel feeding pipe 10, inert material Feed into tube 11.

[0022] see figure 1 , Fuel gas feed pipe 2 in the center of the furnace passes through the air chamber 8 and the air distribution plate 7 into the center of the furnace in the vertical direction. see figure 2 , The gas feed pipe 2 in the hearth center passes into the dense-phase area of the hearth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com