Intelligent control system for boiler and its multiple type of coal control method

A technology of an intelligent control system and control method, which is applied in the control of combustion, lighting and heating equipment, etc., can solve problems such as large investment costs, and achieve the effects of reducing labor intensity, improving alarm performance, and outputting data parameters that are stable and accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

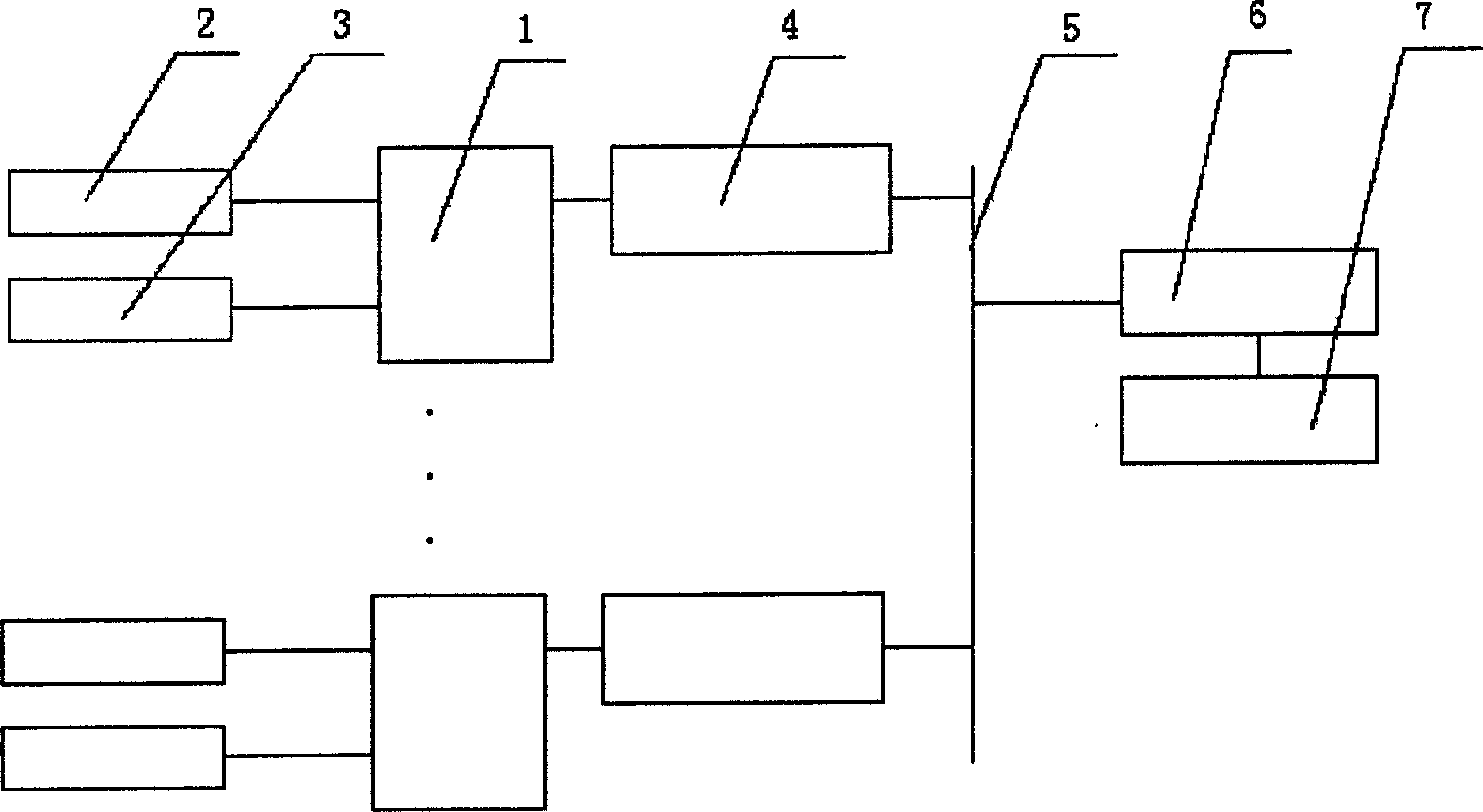

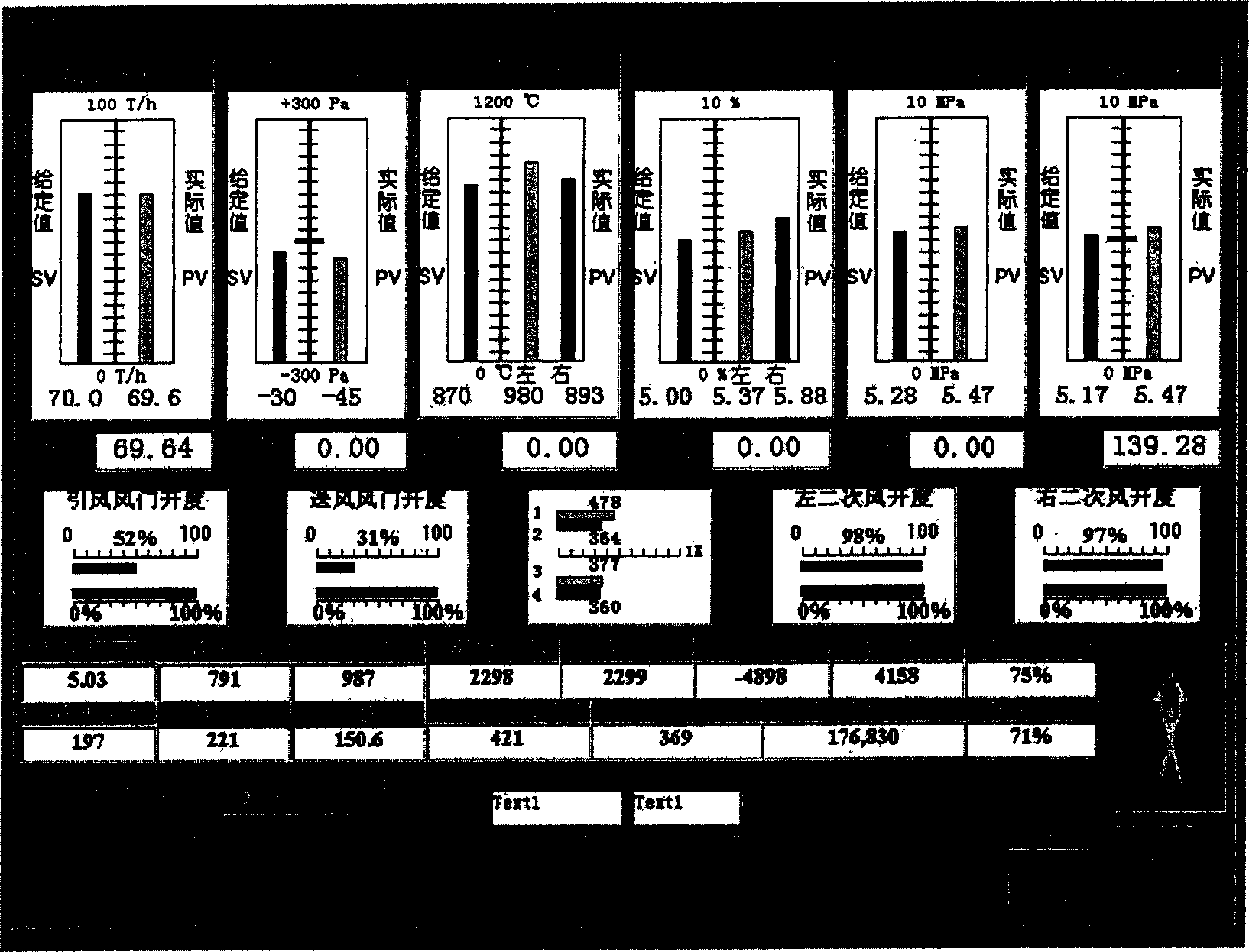

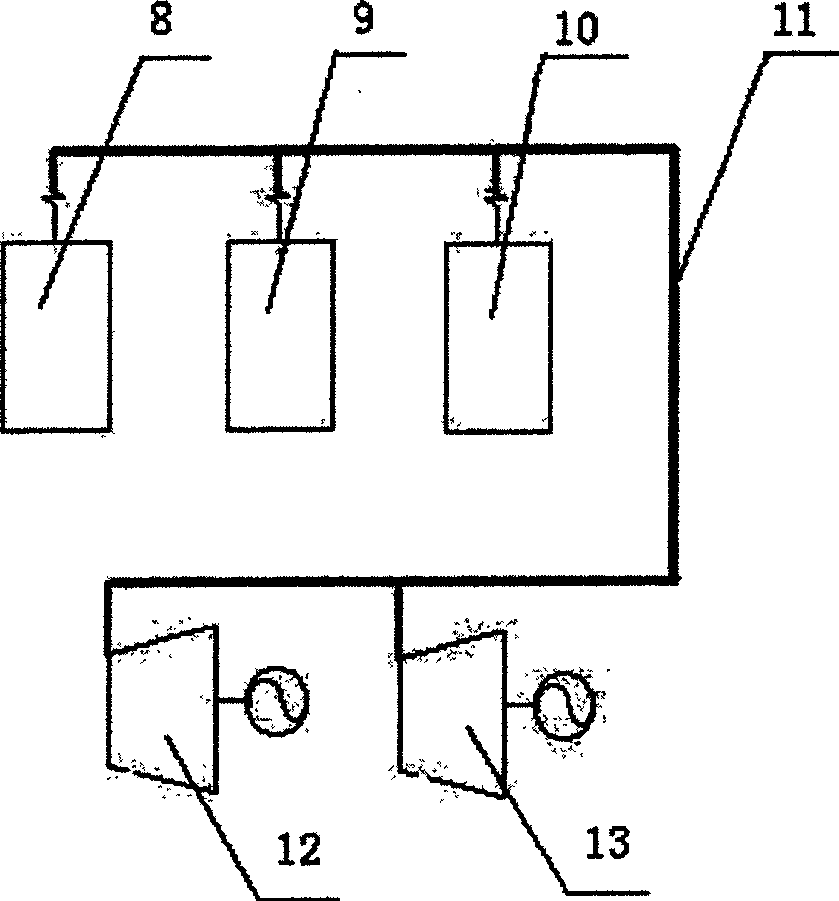

[0024] DUTGK-11 thermal power plant boiler automatic control system:

[0025] This system realizes computer control of 3 furnaces in the thermal power plant. The computer controls the combustion of the boiler according to the load change of the generator, so that the steam flow generated by the boiler meets the requirements of the steam turbine. This system uses the control system of each furnace to connect the data acquisition system 2, alarm output and control system 3, and real-time Ethernet interface 4 with the industrial control computer 1, and connects the real-time Ethernet interface 4 and the data communication network 5. The data communication network 5 is connected to other road control systems.

[0026] Input the standard value of the given steam drum pressure, select the coal type of fuel used, and the system will automatically select the neural network of the coal type in the multi-type coal type neural network, or calculate the primary air volume required by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com