High pressure air clearing method for treating fault of feedback appts. of circulation fluidized bed boiler

A technology for fluidized bed boilers and processing circulation, which is applied in the field of boiler control, and can solve problems such as poor fluidization of local materials, temperature fluctuations of circulating materials, shutdown accidents, etc., and achieve the effect of quickly dealing with blockage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

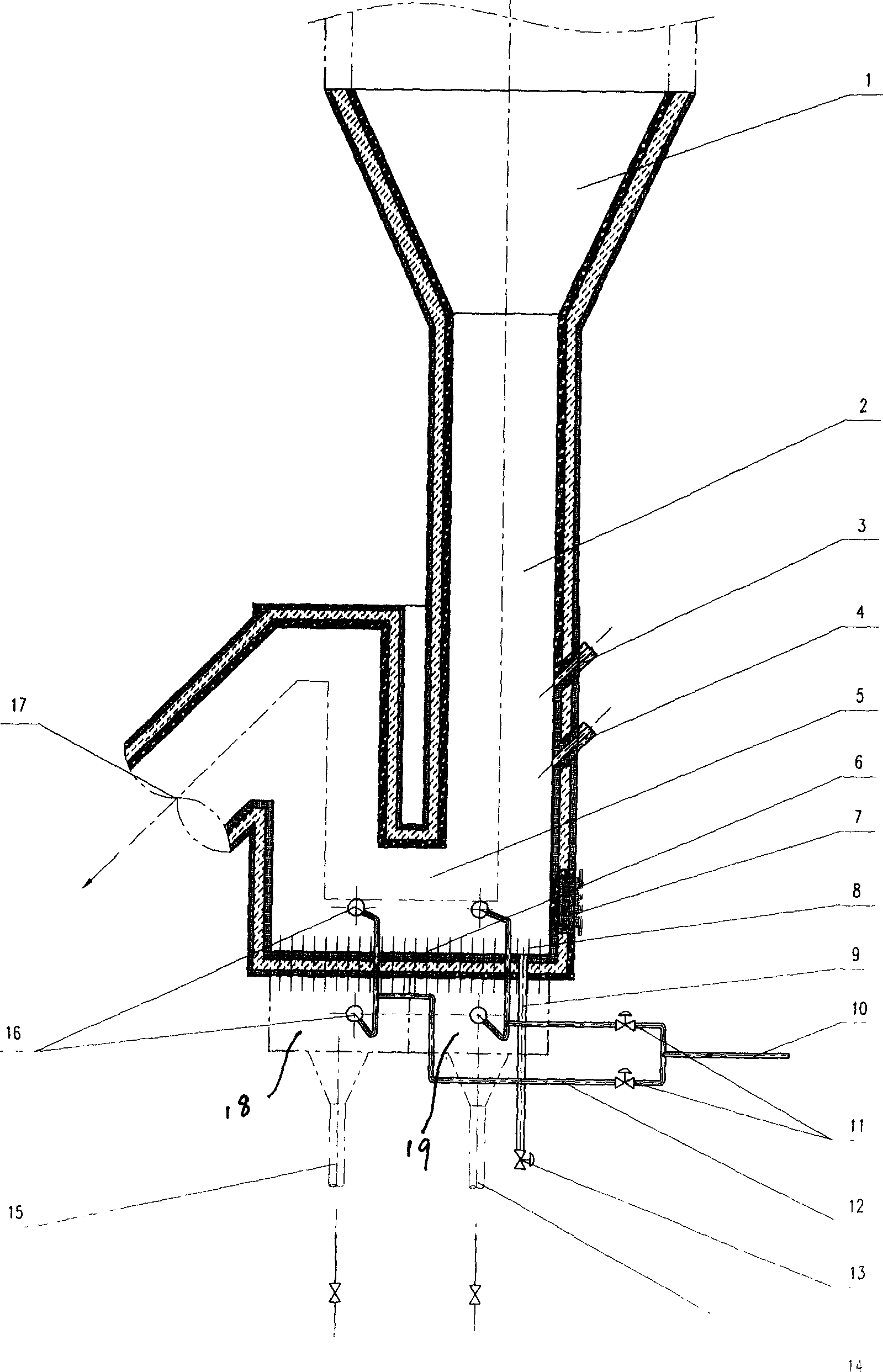

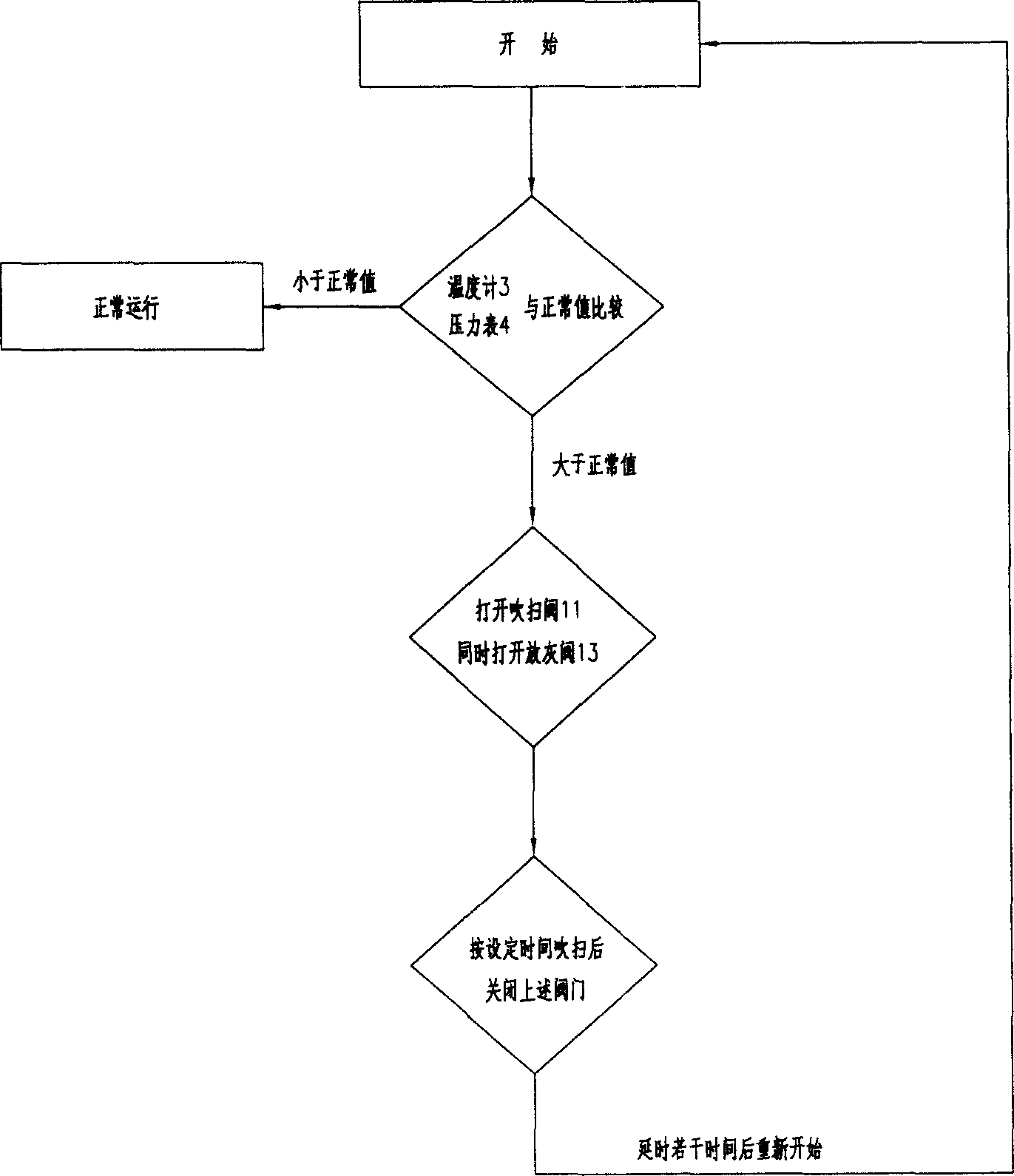

[0011] Such as figure 1 As shown: 1 is the inlet of the feeder, 2 is the riser of the feeder, 3 is the thermocouple installed on the riser 2 of the feeder, 4 is the pressure sensor installed on the riser 2 of the feeder, and 5 is Returner, 6 is the air distribution plate installed at the bottom of the returner 5, 7 is the manhole door for observation and maintenance, 8 is the wind cap installed on the air distribution plate 6, that is, the spout, and 9 is installed on the cloth The ash discharge pipe on the air plate 6, 10 is the main pipe connected to the high-pressure air pipe 12, and the other end is connected to the main pipe of the compressed air system equipped with the original boiler island, and 11 is the control valve for controlling the working state of the high-pressure air pipe 12 , 12 is the high-pressure air pipe, 13 is the ash discharge pipe valve controlling the working state of the ash discharge pipe 9, 14 is the loose air inlet, 15 is the return air inlet, 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com