On-line coal powder pipeline wind-powder leveling method

A pulverized coal pipeline and pulverized coal technology are applied in the direction of combustion methods, fuel supply adjustment, and combustion control, and can solve problems such as difficulty in realization, adverse effects on flame stability and combustion distribution, and lack of leveling means for pulverized coal pipelines. Achieve the balance of pulverized coal concentration, good pulverized coal flow distribution effect, and the effect of reducing the deviation of primary wind speed distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

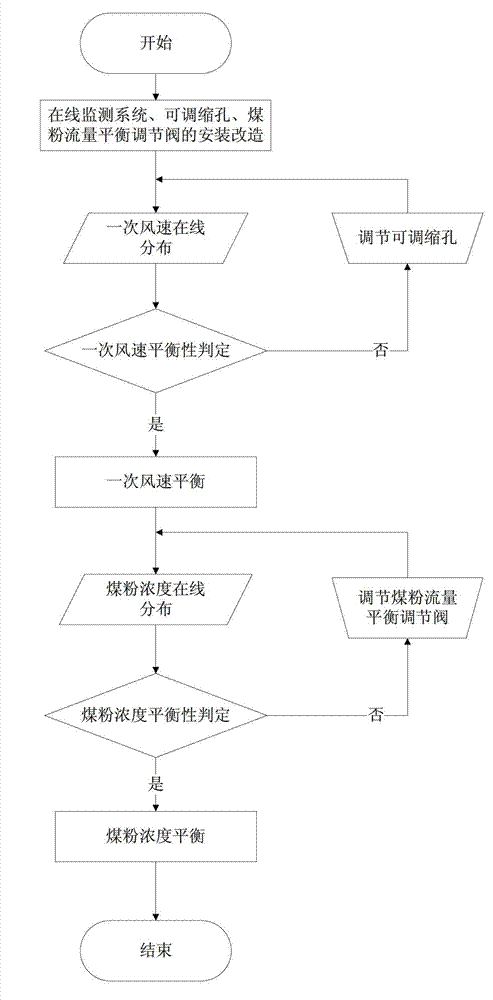

[0027] The technical solutions of the present invention will be described in further detail below in combination with preferred embodiments according to the drawings in the description.

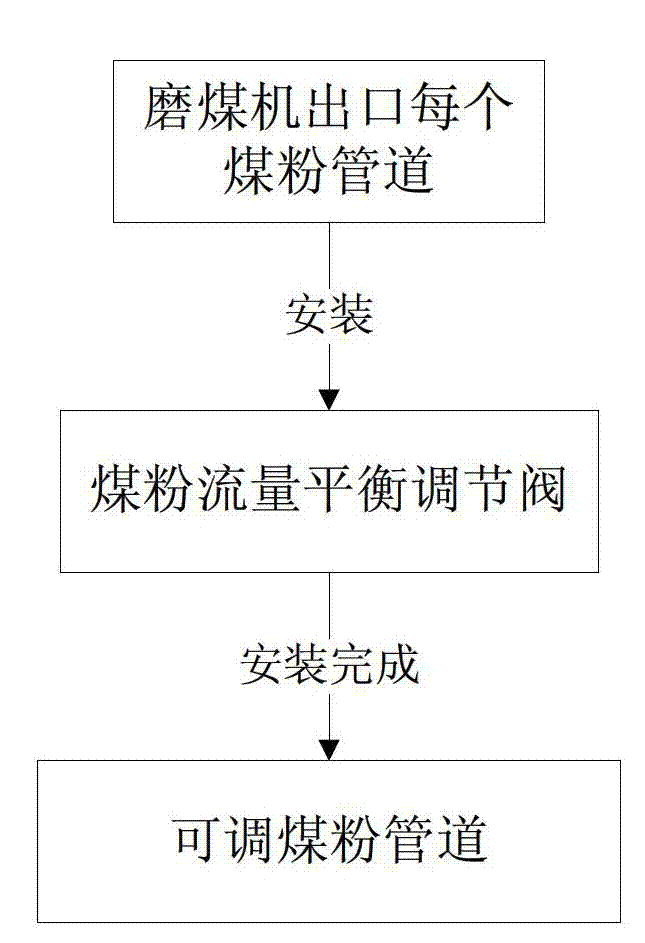

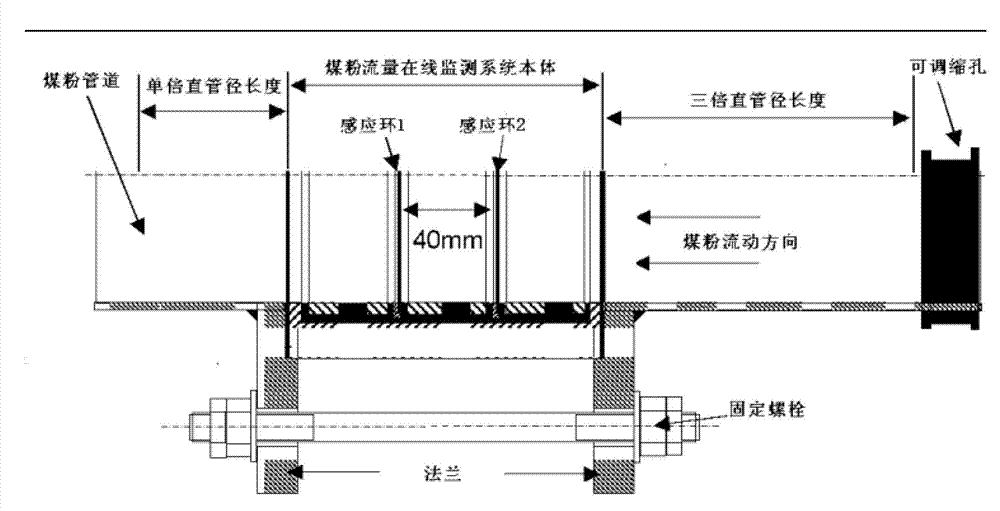

[0028] figure 1 It is a block diagram of the installation of the pulverized coal flow balance regulating valve on the pulverized coal pipeline. The pulverized coal flow balance regulating valve can improve the distribution of pulverized coal but does not hinder the flow of pulverized coal, and the increased flow resistance is small. The design of the pulverized coal flow balance regulating valve is a case-by-case design, which is tailored according to the pipeline characteristics of different power plants. When the pulverized coal flow balance regulating valve is located in the radial direction of the pulverized coal pipeline, its angle is defined as 0 degrees and the opening is the lowest. When the pulverized coal flow balance regulating valve is perpendicular to the radial direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com