Method for optimizing load distribution of boiler

A boiler load and distribution method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of unoptimized load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]A method for optimizing boiler load distribution, specifically the following steps:

[0040] (1) For the total number of boilers is ( ) The production unit of each boiler separately collects the load and corresponding boiler efficiency data during the production process of each boiler, and establishes a database; the specific boiler operating load parameters and corresponding efficiency data can be obtained through the boiler real-time operation database, or Measure and collect directly through instruments and equipment;

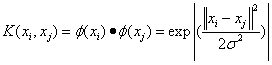

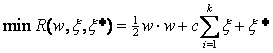

[0041] (2) Use the support vector machine method to model each boiler separately, establish the model between the load of each boiler and each combustion efficiency, and establish a total of models ; The specific modeling method is as follows:

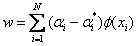

[0042] The input parameters and output parameters used to model the samples are expressed as ,in Indicates the first Set as input data the operating load parameters of the boiler, Indicates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com