Power station boiler combustion optimization method based on data driven case matching

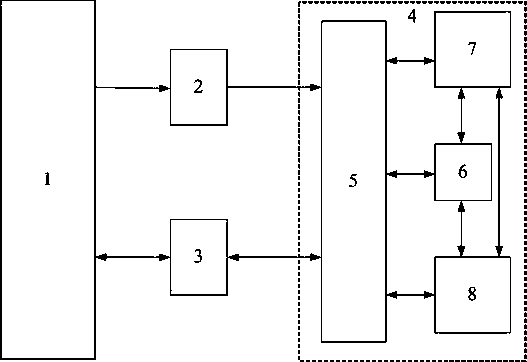

A technology for combustion optimization and power station boilers, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problem of inability to deeply analyze data rules, waste of data resources, diversity, dynamics and cross-cutting manual analysis and processing difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

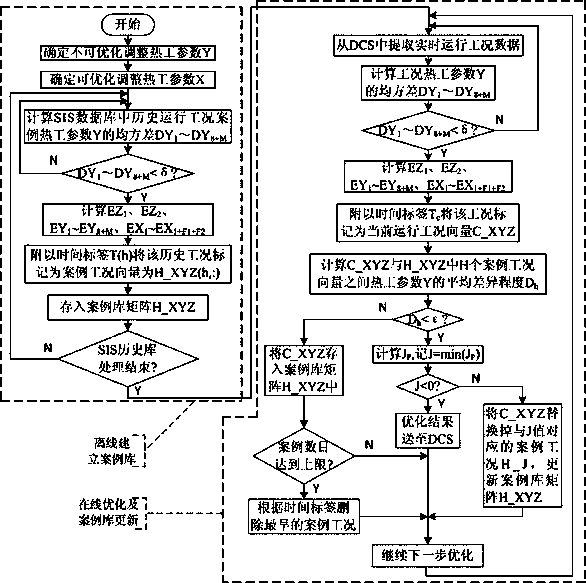

Method used

Image

Examples

Embodiment

[0061] Example: A 600MW boiler is a supercritical variable pressure direct current furnace, which is a once-reheated, wall-type tangentially fired, balanced ventilation, tightly closed, solid-state slag discharge, all-steel frame, and a fully-suspended structure Π-type boiler. The number of coal mills is M=6, the secondary air is F1=5, and the overburning air is F2=2.

[0062] Thermal parameter Y applied to combustion optimization includes unit load Y 1 (MW), main steam flow Y 2 (t / h), main steam pressure Y 3 (MPa), main steam temperature Y 4 (°C), reheat steam pressure Y 5 (MPa), reheat steam temperature Y 6 (°C), burner swing angle Y 7 (°), bellows furnace differential pressure Y 8 (kPa), coal mill running signal Y 9 (t / h), ..., Y 14 (t / h); thermal parameter X includes flue gas oxygen content X 1 (%), the opening degree of the secondary air door of each layer X 2 (%)~X 6 (%), the opening of the burnout damper of each layer X 7 (%), X 8 (%); comprehensive perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com