Power boiler low NOx combustion method and control system based on wind powder closed-loop control

A technology of closed-loop control and power plant boilers, which is applied in the direction of controlling combustion, lighting and heating equipment, which can solve problems such as gaps and achieve the effect of reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

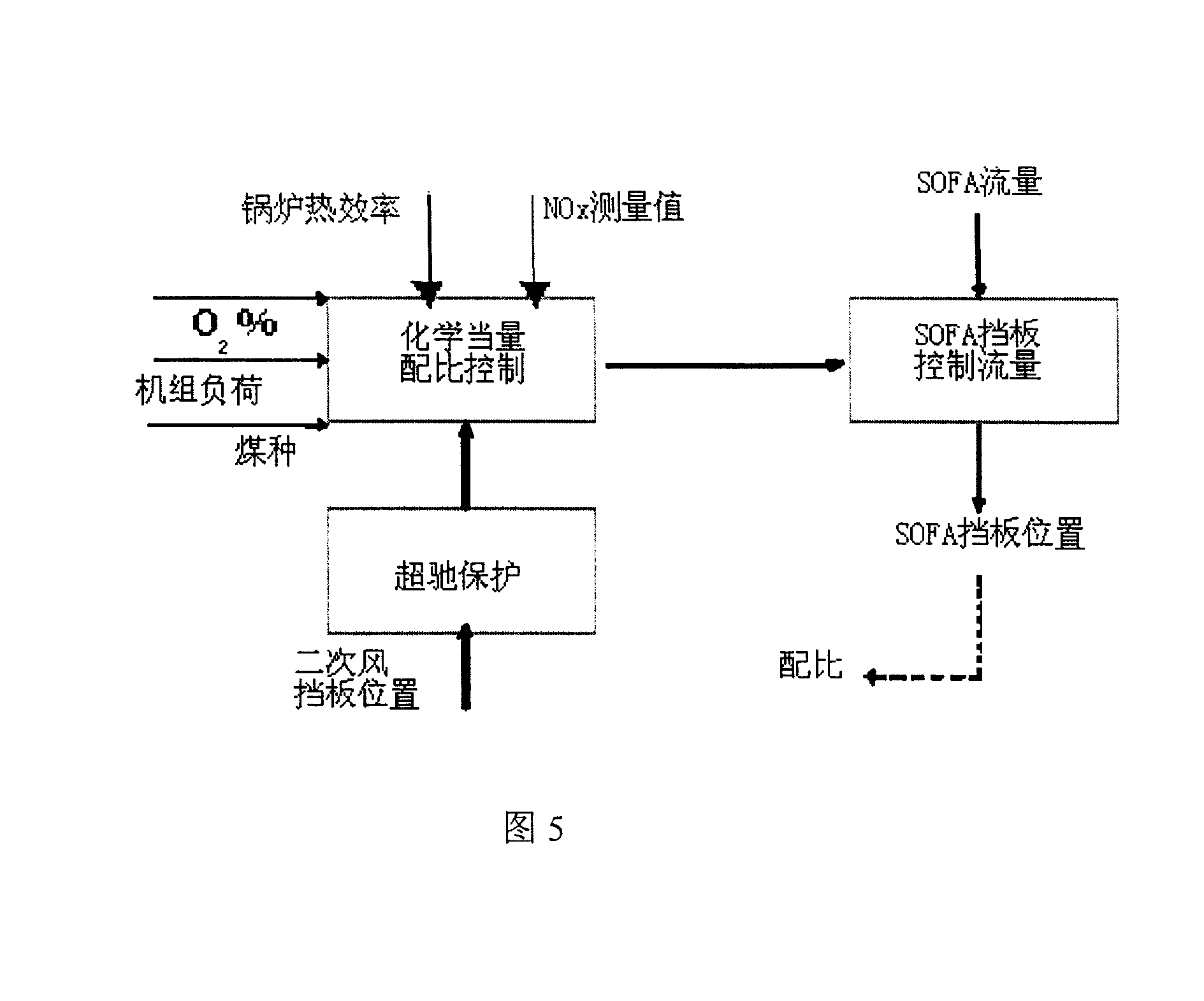

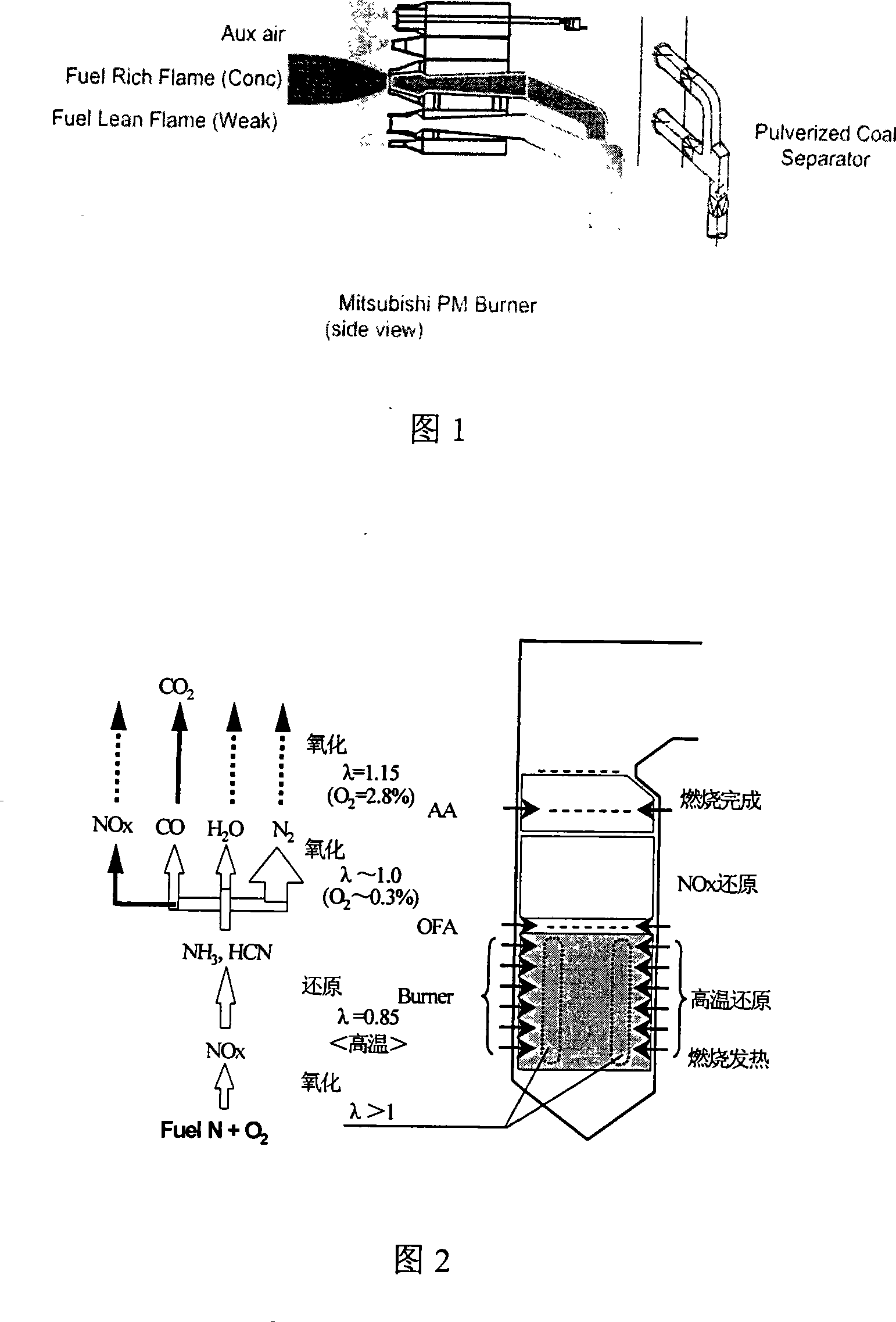

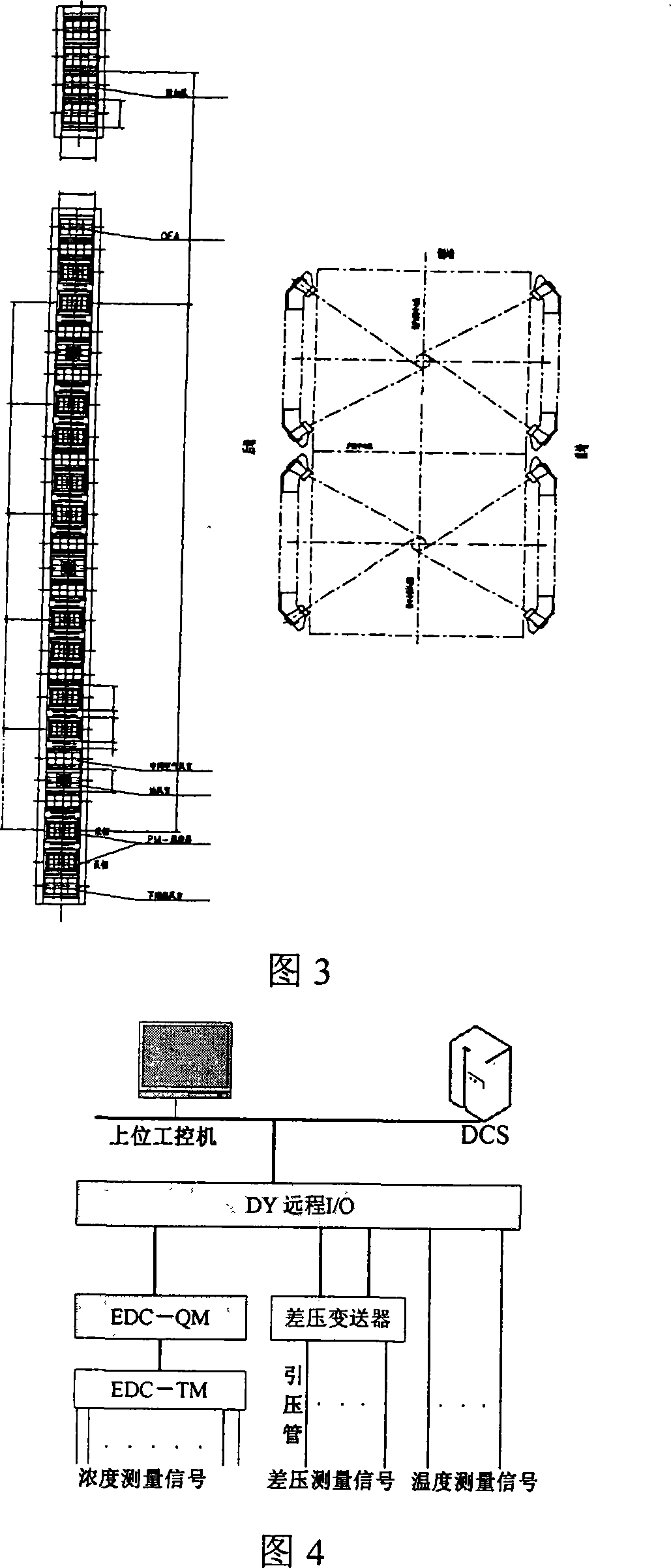

[0014] The present invention is described in further detail below by accompanying drawing and embodiment: 1000MW ultra-supercritical boiler adopts the technology of Mitsubishi Corporation of Japan, single furnace, Π type arrangement, combustion mode are PM (PollutionMinimum) main burner, as shown in Figure 1, and MACT (Mitsubishi Advanced CombustionTechnology) type low NOx staged air combustion system, as shown in Figure 2, and the reverse double tangential circular combustion method, as shown in Figure 3. This PM type burner uses the centrifugal action of the front elbow of each pulverized coal nozzle to divide the fuel air into two airflows of upper and lower thick and thin to form vertical thick and thin combustion, so that the dense phase side of the burner forms a local anoxic combustion to achieve the same burner. Staged combustion, in addition, the overall staged combustion technology in the MACT furnace is adopted to form a reducing atmosphere in the burner area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com