Boiler combustion optimizing control system and optimizing control method based on accurate measurement system

A technology for optimizing control and boiler combustion, applied in the control of combustion, lighting and heating equipment, etc., can solve the problems of low installation rate, affecting accuracy, accuracy and stability, etc., to reduce losses, reduce coal consumption, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

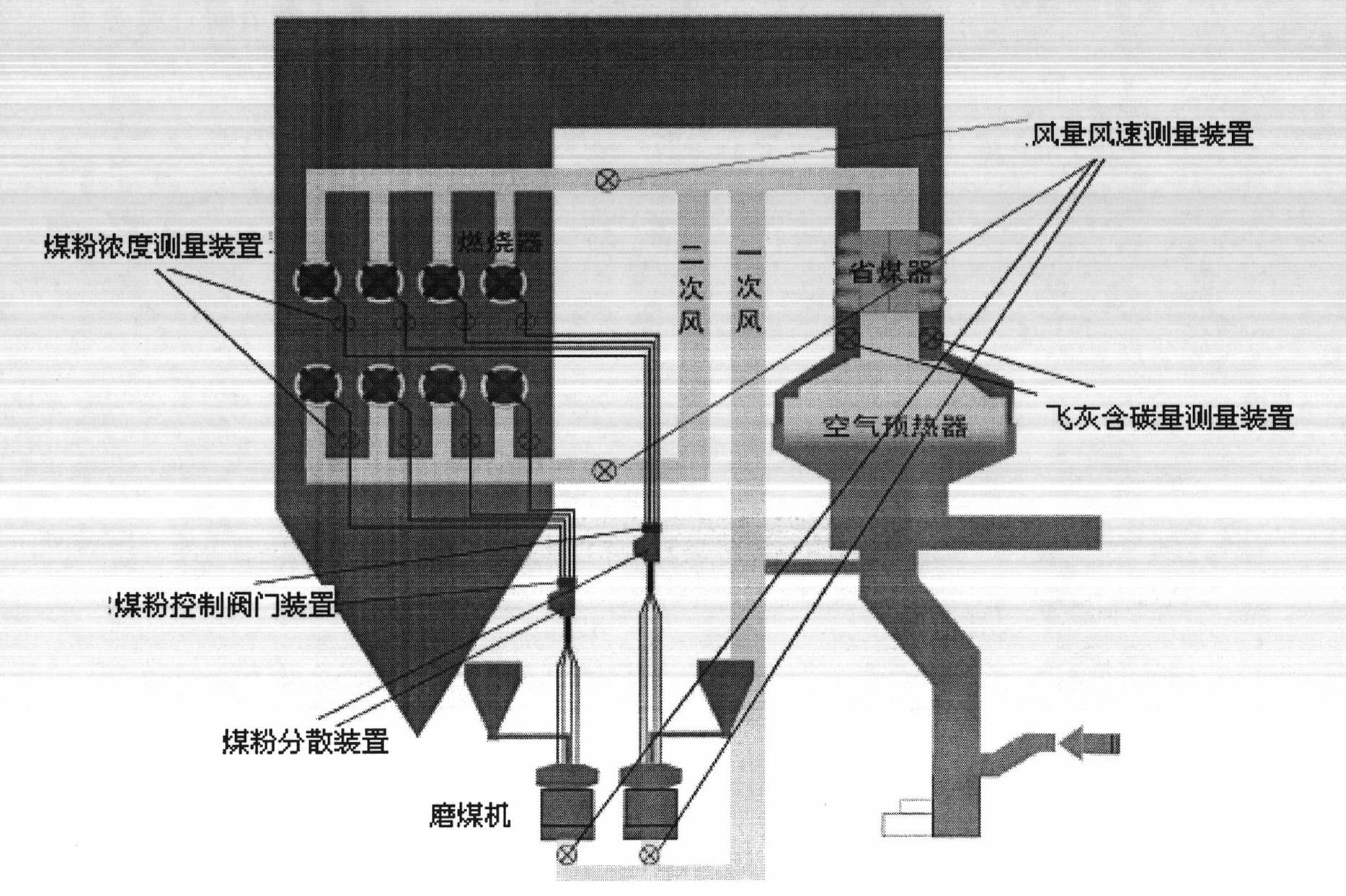

[0047] The technical solution of the present invention will be further described in detail below based on the drawings of the specification and the preferred embodiments.

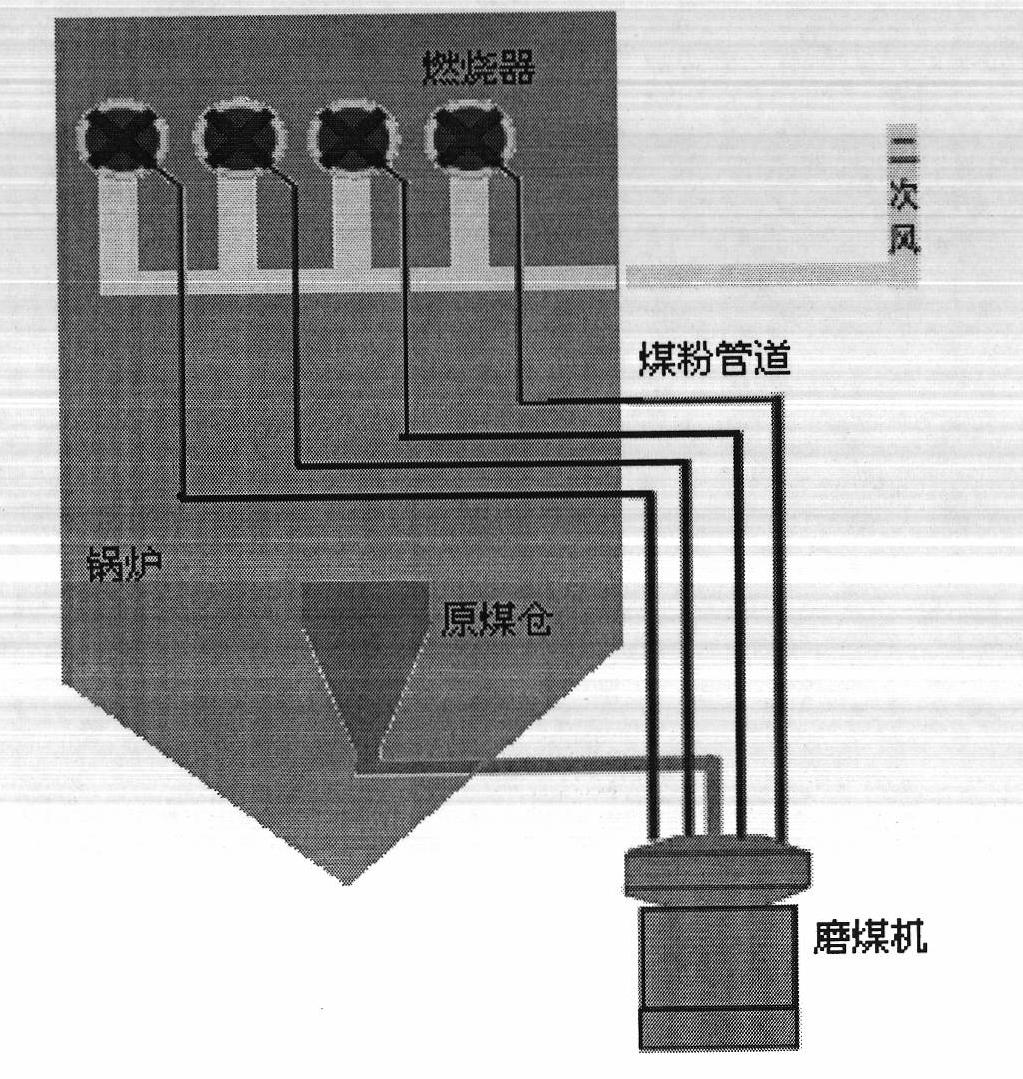

[0048] figure 1 For the existing pulverized coal pipeline diagram, there are several pipelines (4-6, depending on the specific unit capacity) directly from the coal mill to the burners. There is no pulverized coal concentration, flow rate and flow rate on the pulverized coal pipeline. Online measuring device.

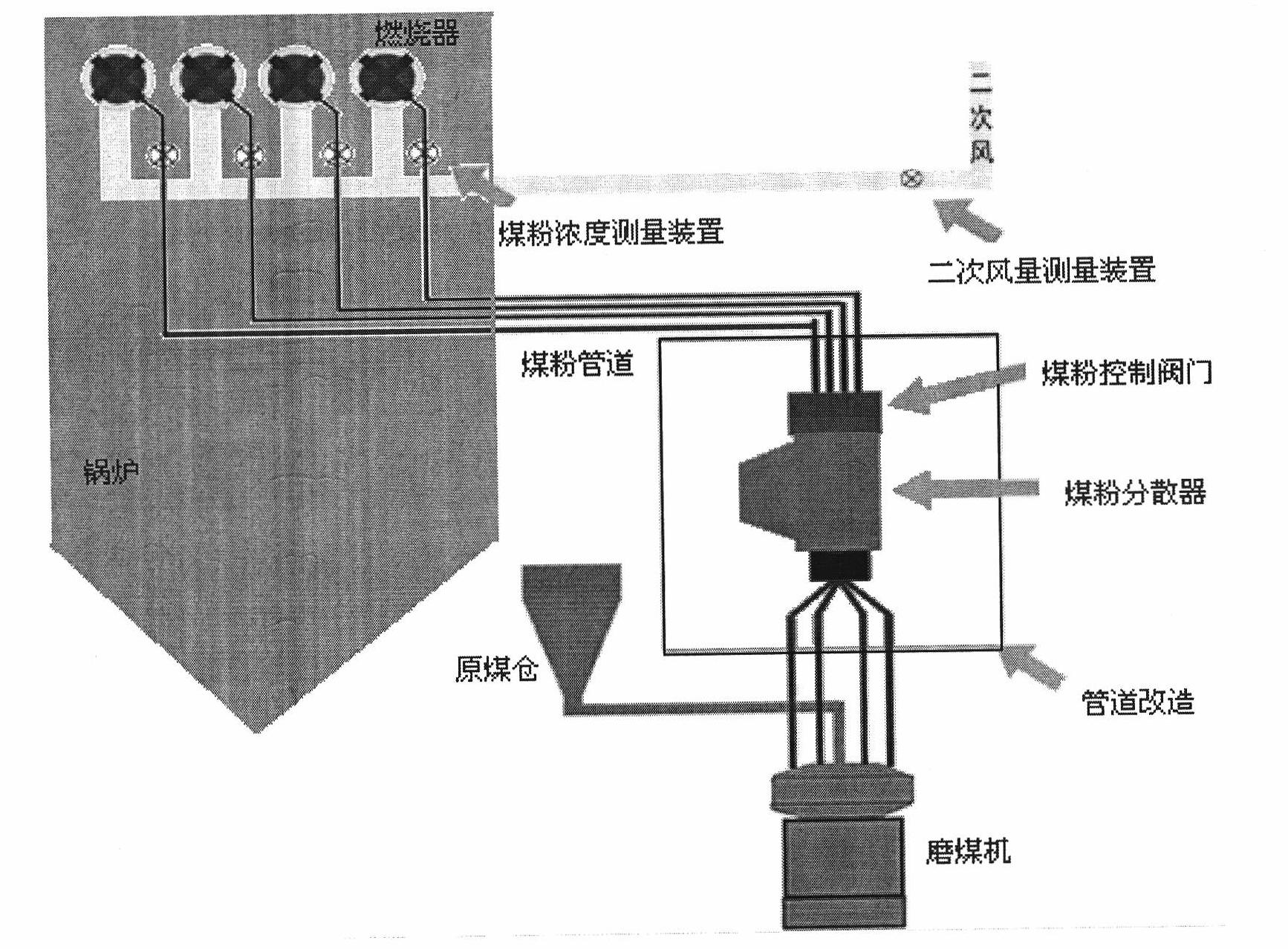

[0049] figure 2 This is a schematic diagram of the pulverized coal pipeline after the pipeline transformation of the present invention. The pulverized coal pipeline at the outlet of the original multi-channel coal mill is transformed into a general pipeline, and the pulverized coal disperser and Corresponding pulverized coal control valve device for even distribution of pulverized coal. The pulverized coal disperser is installed at the front end from the outlet of the coal mill to the distribution point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com