Feedforward PID (proportion, integration and differentiation) control based rapid high-precision relative pointing control method of noncoplanar rendezvous orbit

A different-plane crossing and pointing control technology, applied in attitude control, adaptive control, general control system, etc., can solve the problem of fast and high-precision tracking and pointing without satellite attitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0049] A fast and high-precision relative pointing control method for fast-changing tracks across different planes based on feed-forward PID control, including the following steps:

[0050] Step 1: Determine the desired pose:

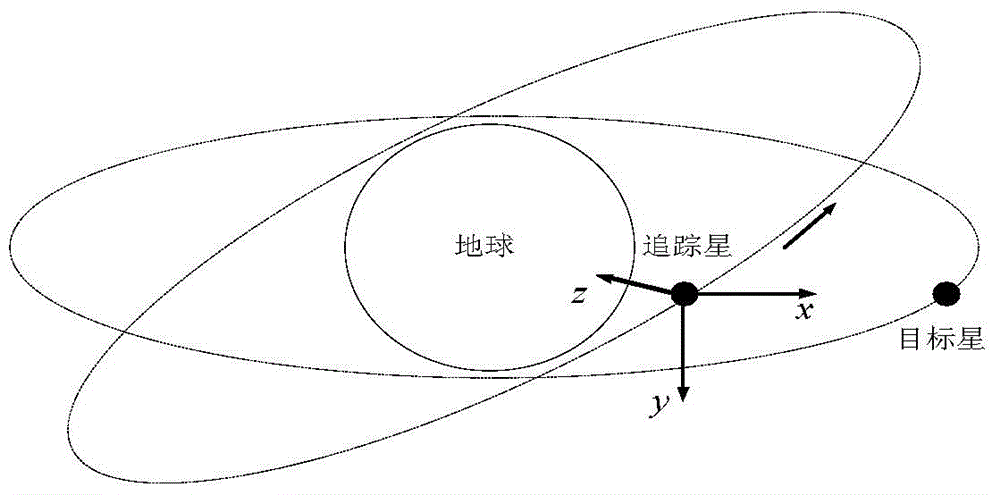

[0051] The tracking star and the target star are located on different orbits, and the tracking star needs to detect the position of the target autonomously; in order to make the laser emitter or observation equipment of the tracking star always point to the target star, the desired attitude must be determined first, so that the problem of pointing to the target can be easily solved. It becomes a problem of attitude tracking; due to the limited detection range, laser attack or observation and monitoring can only be carried out when the distance between the tracking star and the target star is relatively close. , at this time, the expected attitude often changes quickly (the embodiment of "fast change"), so it is necessary to have a faster response speed ...

specific Embodiment approach 2

[0077] Specific implementation mode two: the implementation process of step 3 of this embodiment mode is:

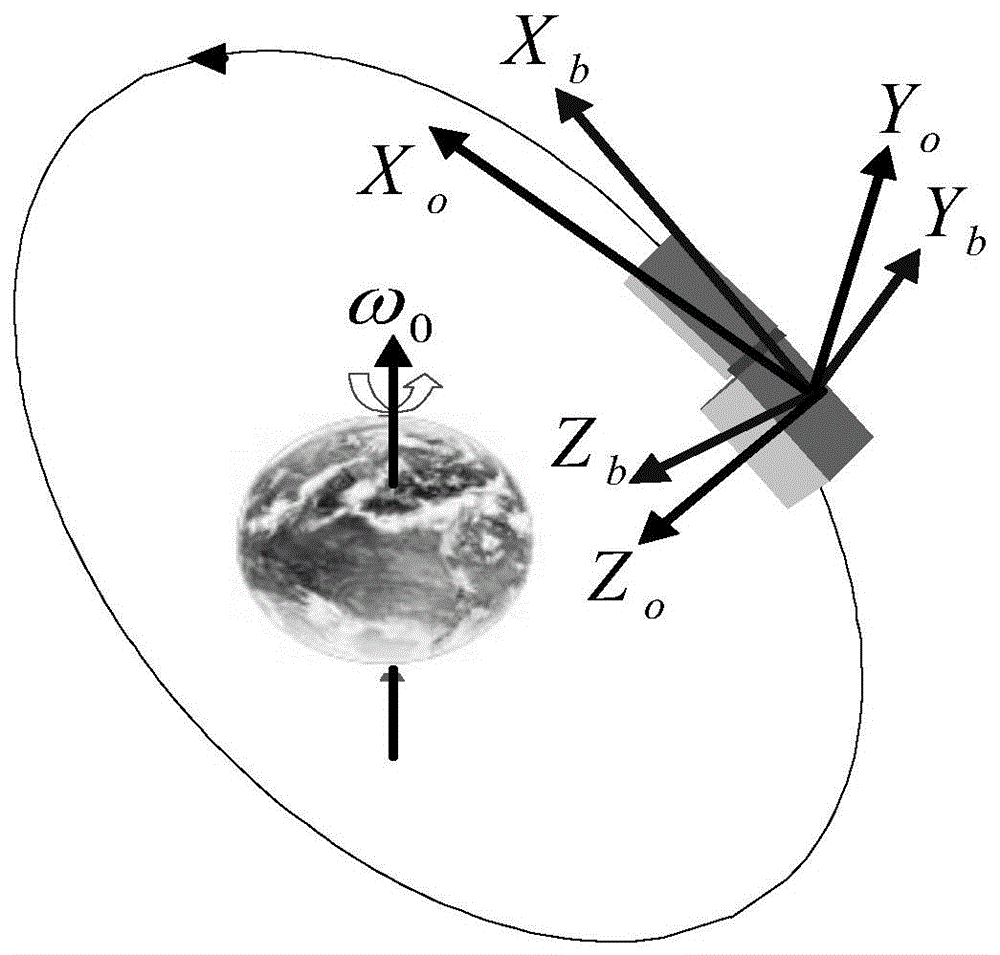

[0078] The angular velocity ω of the tracking star in the inertial space is equal to the angular velocity ω of the tracking star body coordinate system relative to the attitude reference coordinate system br The implicated angular velocity ω of the center-of-mass inertial coordinate system relative to the attitude reference coordinate system ri the sum of

[0079] ω=ω br +ω ri (8)

[0080] In inertial orientation flight mode

[0081] At this time, the reference coordinate system is the center of mass inertial coordinate system, ω ri = 0, yes

[0082]

[0083] C X (i), C Y (i), C Z (i) the rotation matrix in the coordinate system conversion process;

[0084] ψ is the yaw angle; is the pitch angle; is roll angle; ω x , ω y , ω z are the components of the tracking star angular velocity ω in the x-axis, y-axis, and z-axis in the center-of-mass inertial...

specific Embodiment approach 3

[0099] Specific implementation mode three: the implementation process of step 4 of this embodiment mode is:

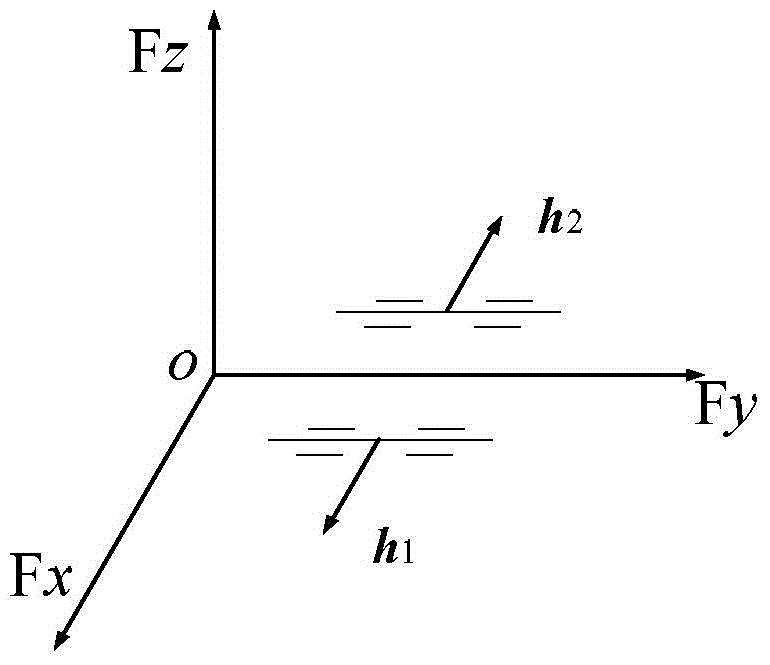

[0100] Due to the large change in the expected attitude near the intersection point of the orbits of the two stars, the requirements for the control torque are relatively high; although the thruster can provide a large torque, the output torque is not continuous, and the command torque cannot be accurately tracked, which destroys the control System performance; In the feedforward PID attitude tracking control, the accuracy of the control quantity is required to be higher, and it is more likely to cause chattering when the thruster is used as the actuator, and the ideal control effect cannot be achieved;

[0101] In the present invention, only the torque requirement of the yaw axis is relatively large, and the torque requirements of the other two axes are very small. The flywheel and the CMG can be used in combination, that is, the yaw axis is controlled by two parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com