A Method for Identifying Fault Sections and Fault Branches of Collecting Lines in Wind Farms

A technology for collecting lines and fault sections is applied in the field of identification of fault sections and fault branches of power collecting lines in wind farms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

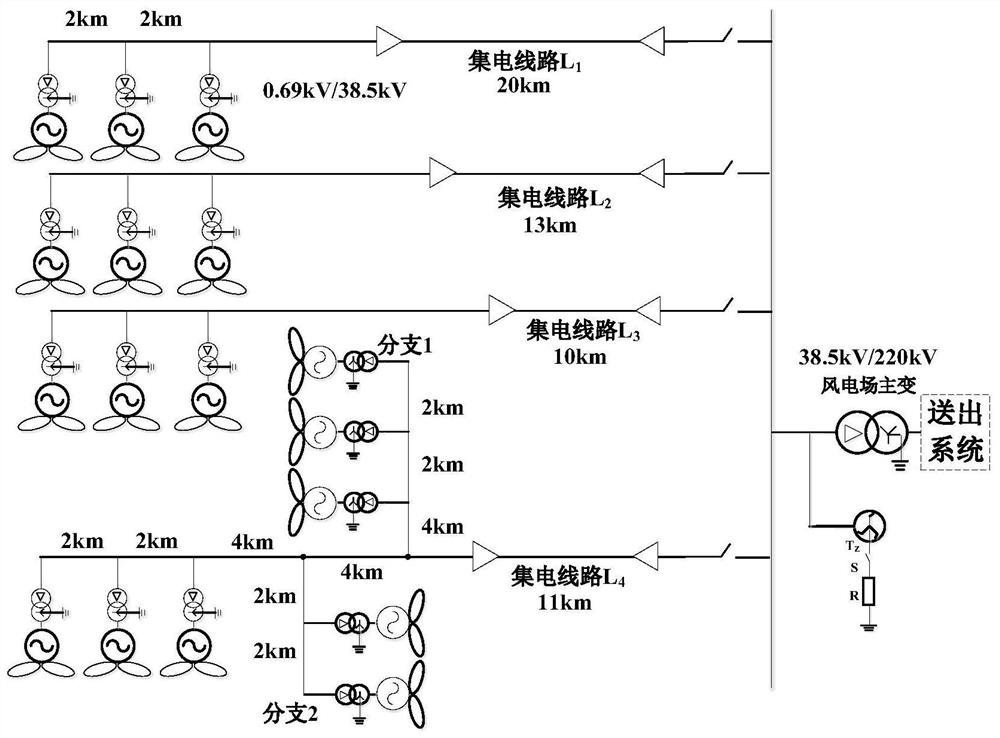

[0059] Embodiment 1: as figure 1 As shown in , the simulation model of a typical wind farm power collection system is constructed, and the specific parameters of the model are as follows:

[0060] (1) There are 4 collector lines L on the 35kV collector bus 1 ~ L 4 , where L 1 ~ L 3 Each line has 3 double-fed wind turbines, L 4 Containing branches, there are a total of 8 double-fed wind turbines; a total of 17 double-fed wind turbines are connected. The doubly-fed wind turbine is connected to the collector line via a 0.69kV / 38.5kV Y / △-type box-type transformer booster. The capacity of each wind turbine is 2MW, and the total capacity of wind turbines is 17*2MW=34MW.

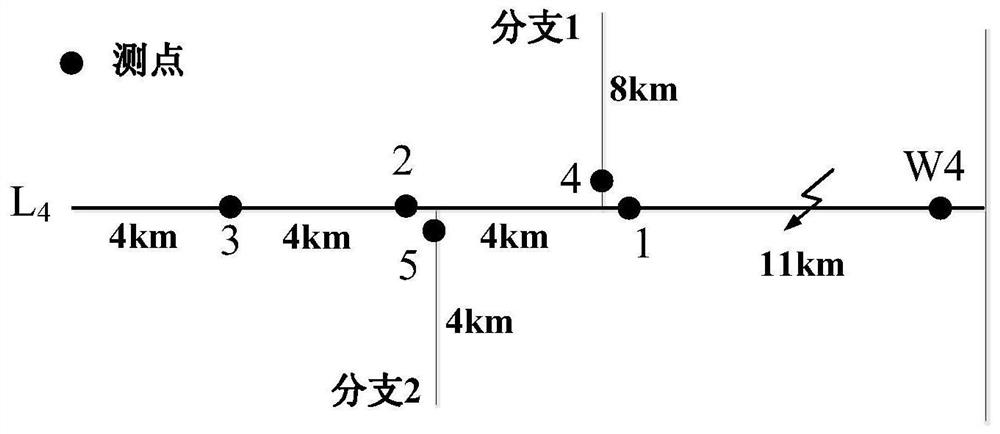

[0061] (2) L 1 ~ L 4 The total length of the trunk line is: 24km, 17km, 14km, 23km, of which L 1 ~ L 4 Upstream are cable lines with lengths of 20km, 13km, 10km, and 11km respectively. Downstream wind turbines are overhead lines, and the distance between every two wind turbines is 2km. L 4 The lengths o...

Embodiment 2

[0067] Embodiment 2: as figure 1 As shown in , the simulation model of a typical wind farm power collection system is constructed, and the specific parameters of the model are as follows:

[0068] (1) There are 4 collector lines L on the 35kV collector bus 1 ~ L 4 , where L 1 ~ L 3 Each line has 3 double-fed wind turbines, L 4 Containing branches, there are a total of 8 double-fed wind turbines; a total of 17 double-fed wind turbines are connected. The doubly-fed wind turbine is connected to the collector line via a 0.69kV / 38.5kV Y / △-type box-type transformer booster. The capacity of each wind turbine is 2MW, and the total capacity of wind turbines is 17*2MW=34MW.

[0069] (2) L 1 ~ L 4 The total length of the trunk line is: 24km, 17km, 14km, 23km, of which L 1 ~ L 4 Upstream are cable lines with lengths of 20km, 13km, 10km, and 11km respectively. Downstream wind turbines are overhead lines, and the distance between every two wind turbines is 2km. L 4 The lengths o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com