A simulation test bench for shield machine cutter head and its use method

A technology for simulating test benches and shield machines, which is applied in the testing of mechanical components, testing of machine/structural components, earthwork drilling and mining, etc., to achieve the effect of meeting strength requirements, reducing risks and costs, and being easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

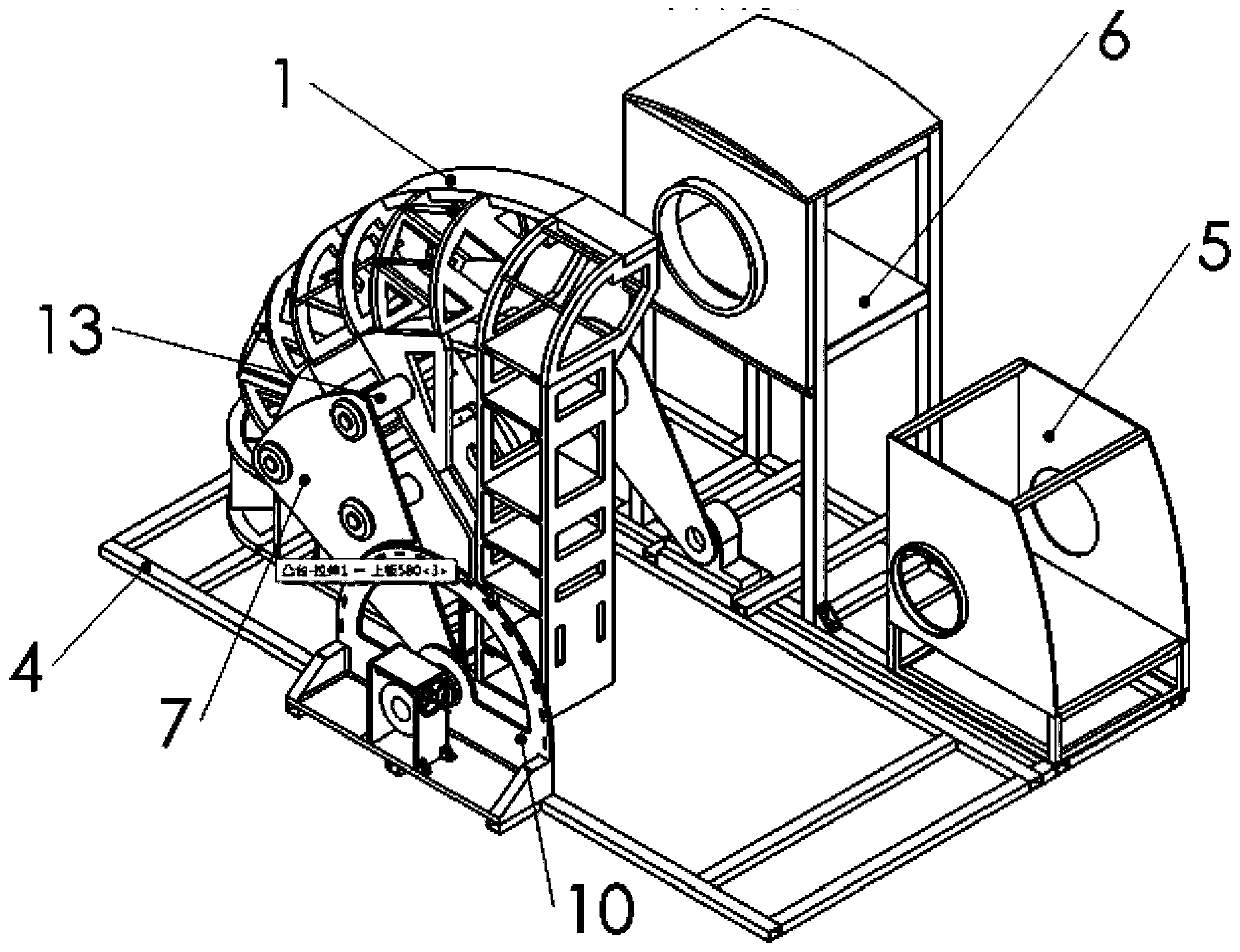

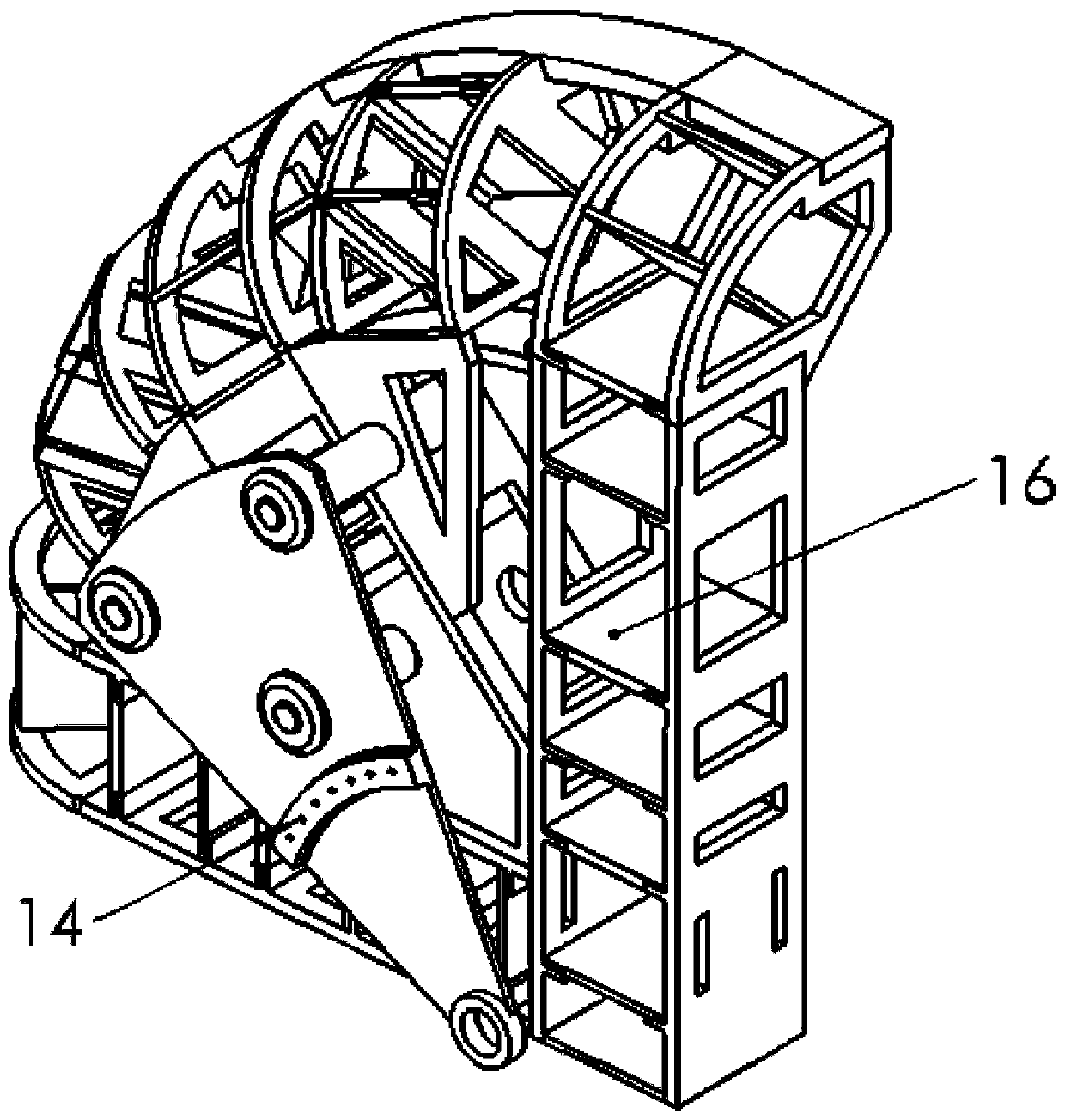

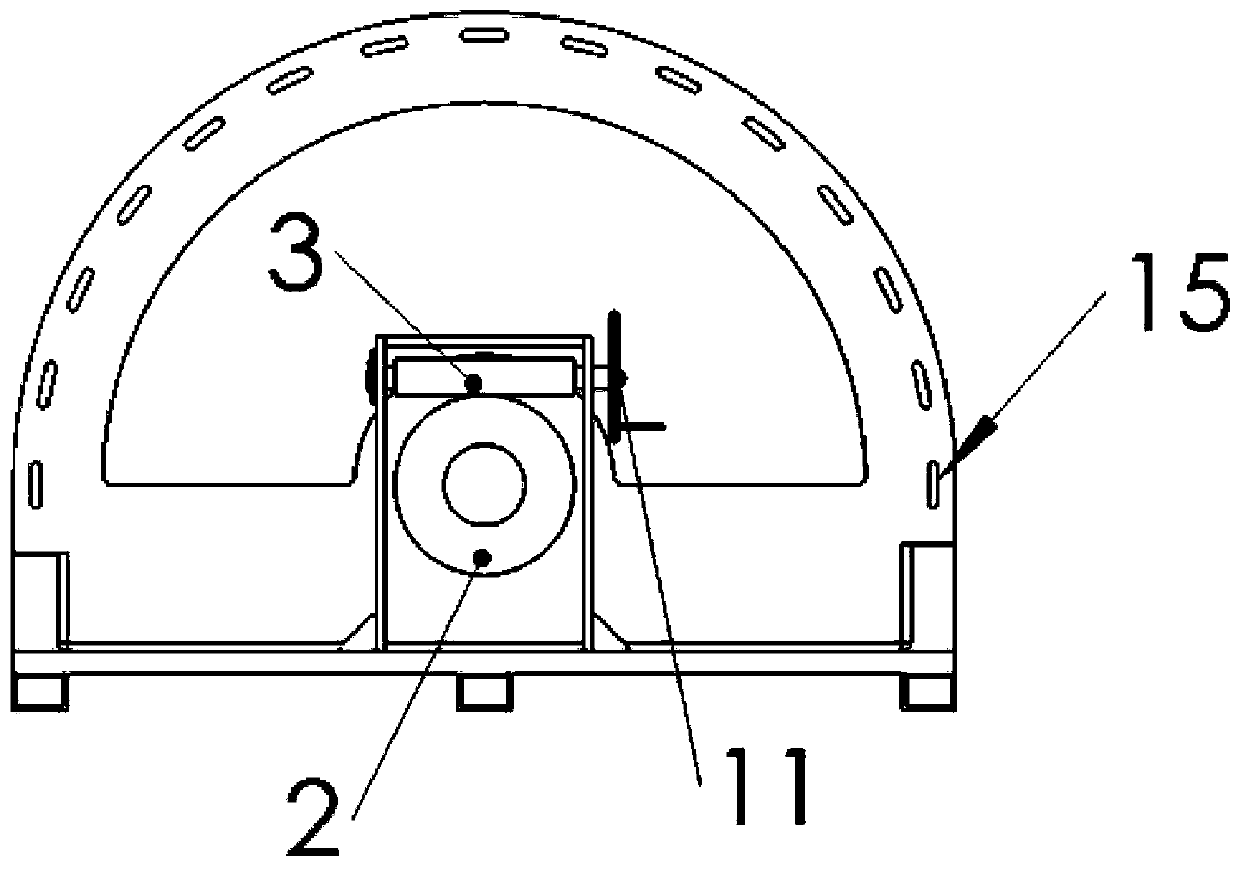

[0032] Such as Figure 1~4 As shown, a simulation test bench of a shield machine cutter head in the present invention includes: a cutter head 1, a worm gear structure, a base 4, a knife storage bin 5, and a manipulator installation bin 6, wherein the cutter head 1 is installed by rotating the mounting plate On the base, the knife storage bin 5 and the manipulator installation bin 6 are all installed on the base 4, and the worm gear structure is installed on the side of the base 4 and the side of the cutter head 1. In the worm gear structure, the shaft of the worm wheel 2 and the cutter head 1 The shafts are coaxially fixed together, and the worm gear structure is provided with a hand wheel 11, and the hand wheel 11 is axially fixedly connected with the worm 3 in the worm gear structure.

[0033] Such as figure 2 As shown, the cutter head is a qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com