Mixed composite material layering method considering multi-scale uncertainty

A technology of composite materials and uncertainty, applied in the direction of neural learning methods, biological neural network models, instruments, etc., can solve the complex and cumbersome design process of hybrid composite materials and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

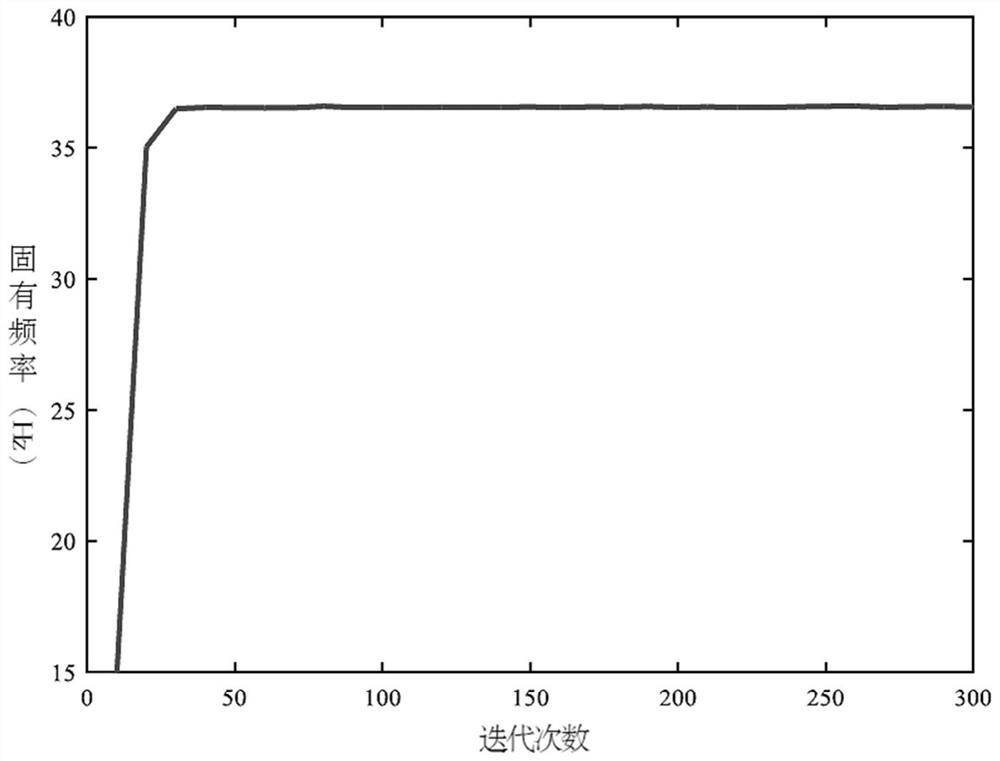

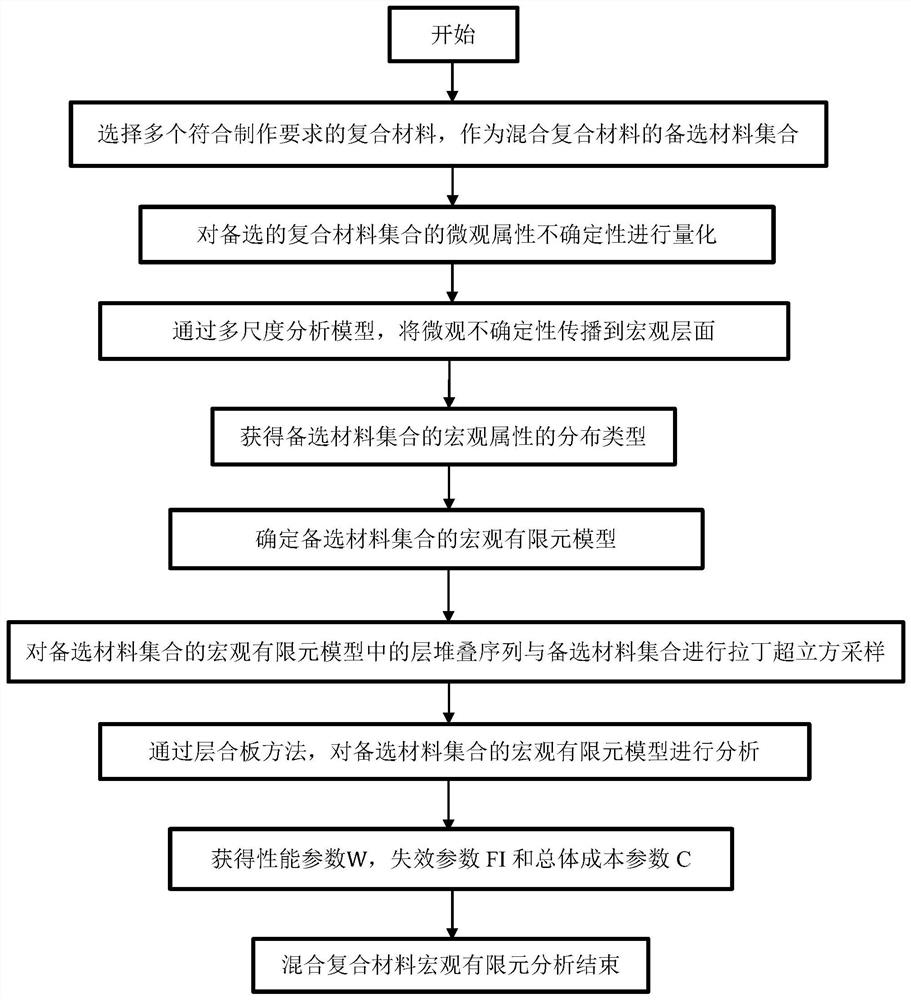

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, but protection scope of the present invention is not limited thereto, and method of the present invention specifically comprises the following steps, as image 3 and Figure 4 Shown:

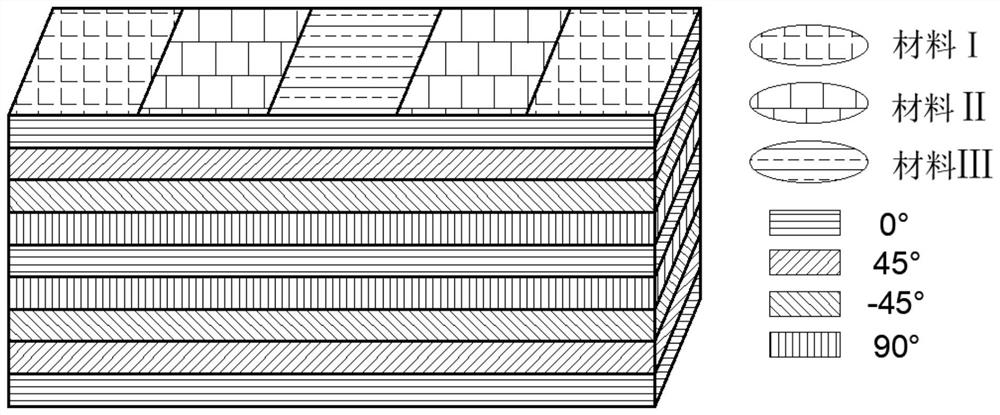

[0055] 1. Determine the basic information of the hybrid composite material to be analyzed: the boundary condition is a nine-layer hybrid composite material simply supported on four sides, the length L=0.508m, the width W=0.406m, and the thickness of each layer is ΔT=0.125mm. The largest overall cost parameter C=9.5USD, the minimum failure probability is Among them, the reliability parameter P f The relationship with the failure parameter FI is: P f =P[1-FI≤0], P is the distributed force on the hybrid composite. Select three candidate materials: material Ⅰ, material Ⅱ, and material Ⅲ. In subsequent calculations, "1" will be used to represent material Ⅰ, "2" will represent mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com