A knife box mechanism of a disc-shaped hob of a shield machine and its use method

A disc-shaped hob and shield machine technology, which is applied to earth drilling, mining equipment, tunnels, etc., can solve the problems of large manpower, financial resources and time, and achieve the simple structure of the cutter box, meet the strength requirements, and be easy to process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with embodiment.

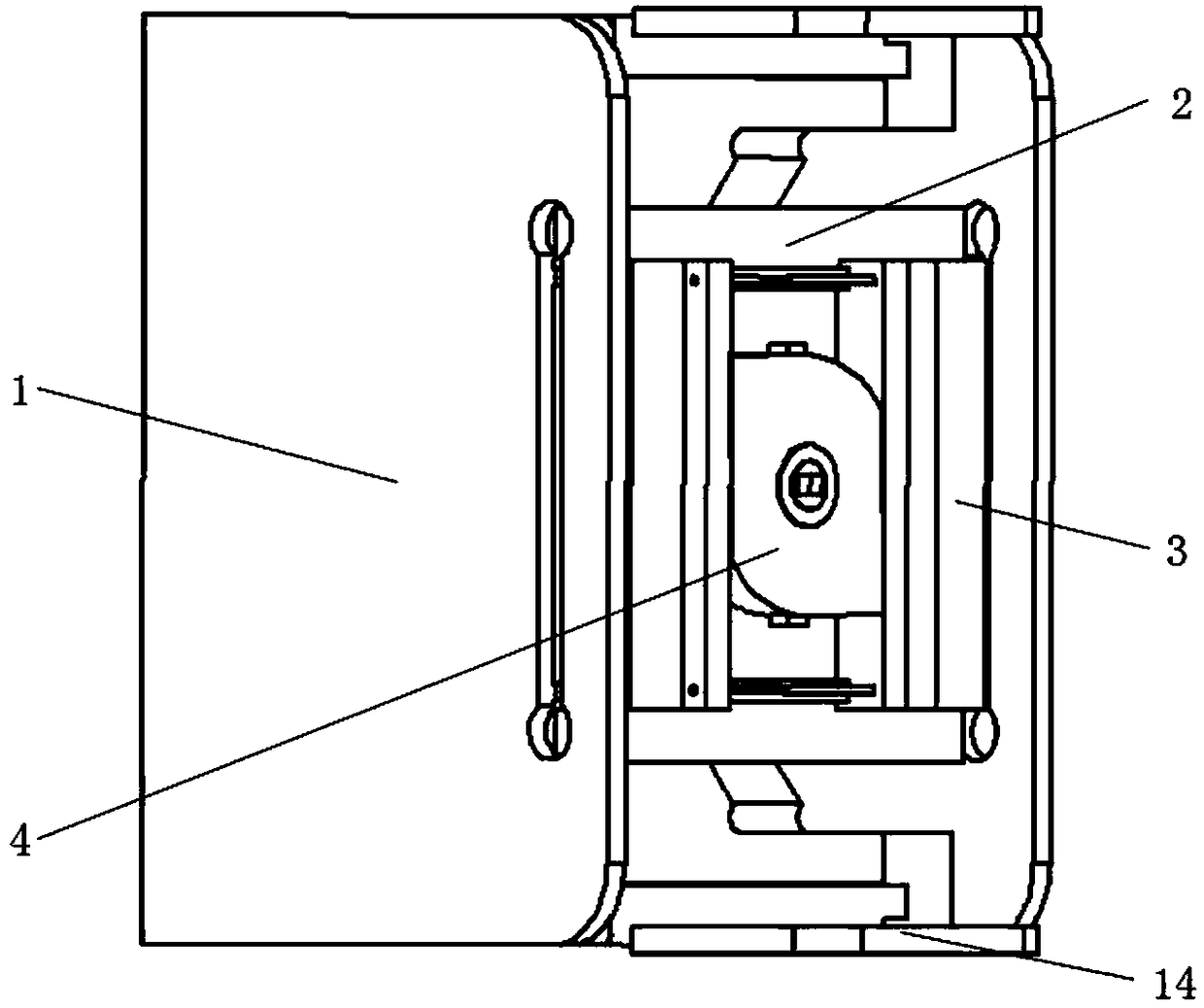

[0055] according to figure 1 As shown, the knife box mechanism of a disc-shaped hob of a shield machine provided by the present invention includes: a box body 1, a hob installation mechanism 2 is arranged in the box body 1, and one side of the hob installation mechanism 2 is affixed to The hob is equipped with a rotating mechanism on the other side.

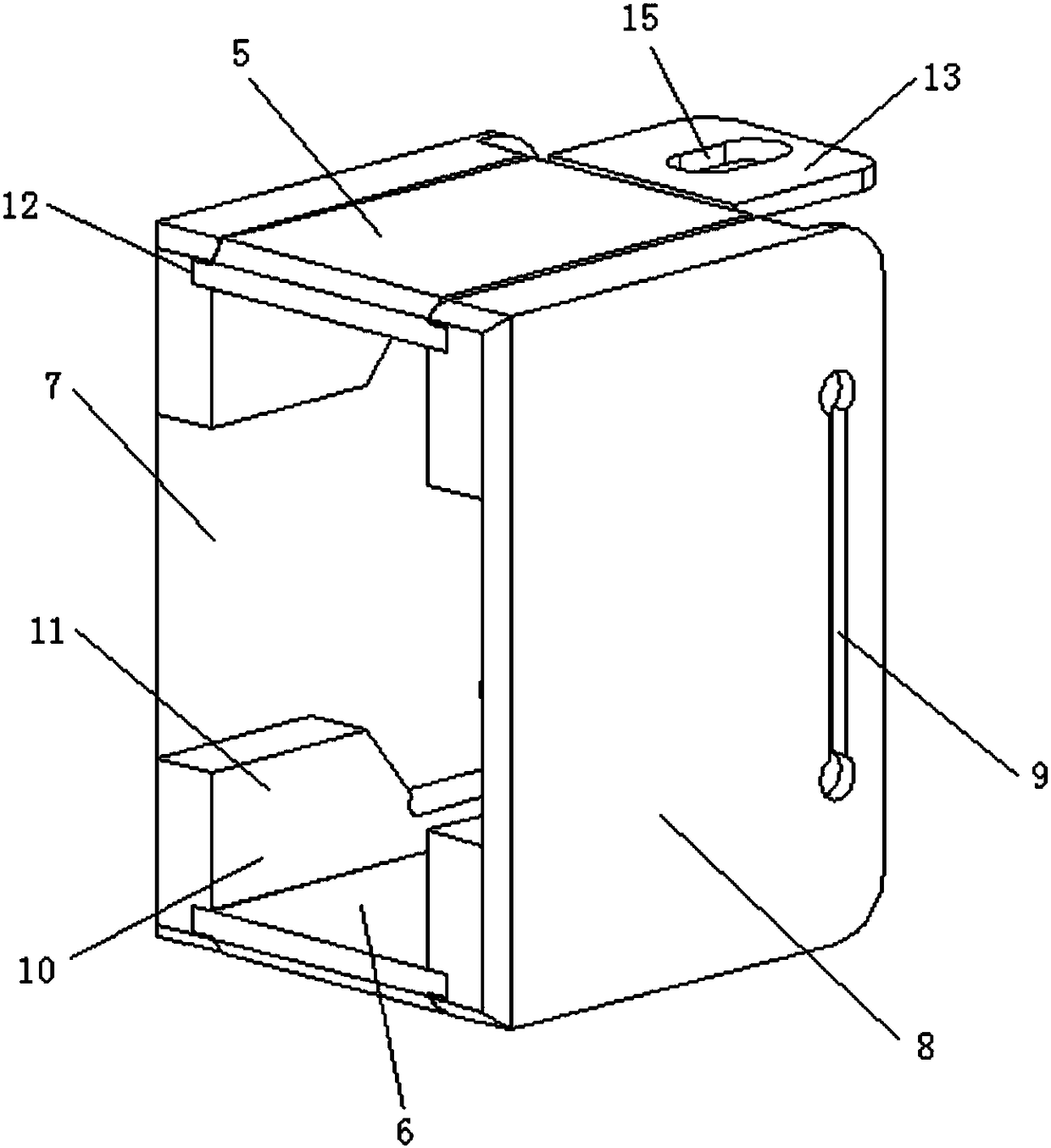

[0056] according to figure 2 As shown, the box body 1 includes an upper box plate 5, a lower box plate 6, a left box plate 7 and a right box plate 8, and the left box plate 7 and the right box plate 8 are correspondingly provided with hob positioning grooves 9, Both ends of the side of the left box plate 7 and the right box plate 8 facing each other are provided with positioning blocks 10, and the positioning blocks 10 on the left box plate 7 and the right box plate 8 are all provided with first protrusions facing each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com