Accelerometer error calibration and compensation method based on rotary mechanism

An accelerometer and rotating mechanism technology, applied in the field of inertial device testing and inertial navigation, can solve the problems of large experiment time, expensive inertial devices, and cumbersome testing process, and achieve the effects of low cost, improved estimation accuracy, and low cost.

Inactive Publication Date: 2010-10-06

BEIHANG UNIV

View PDF0 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The advanced test method described in approach (2) often requires advanced test equipment as the basis. Generally, the test equipment for inertial devices is often expensive, and the test process is cumbersome, requiring a lot of experimental time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

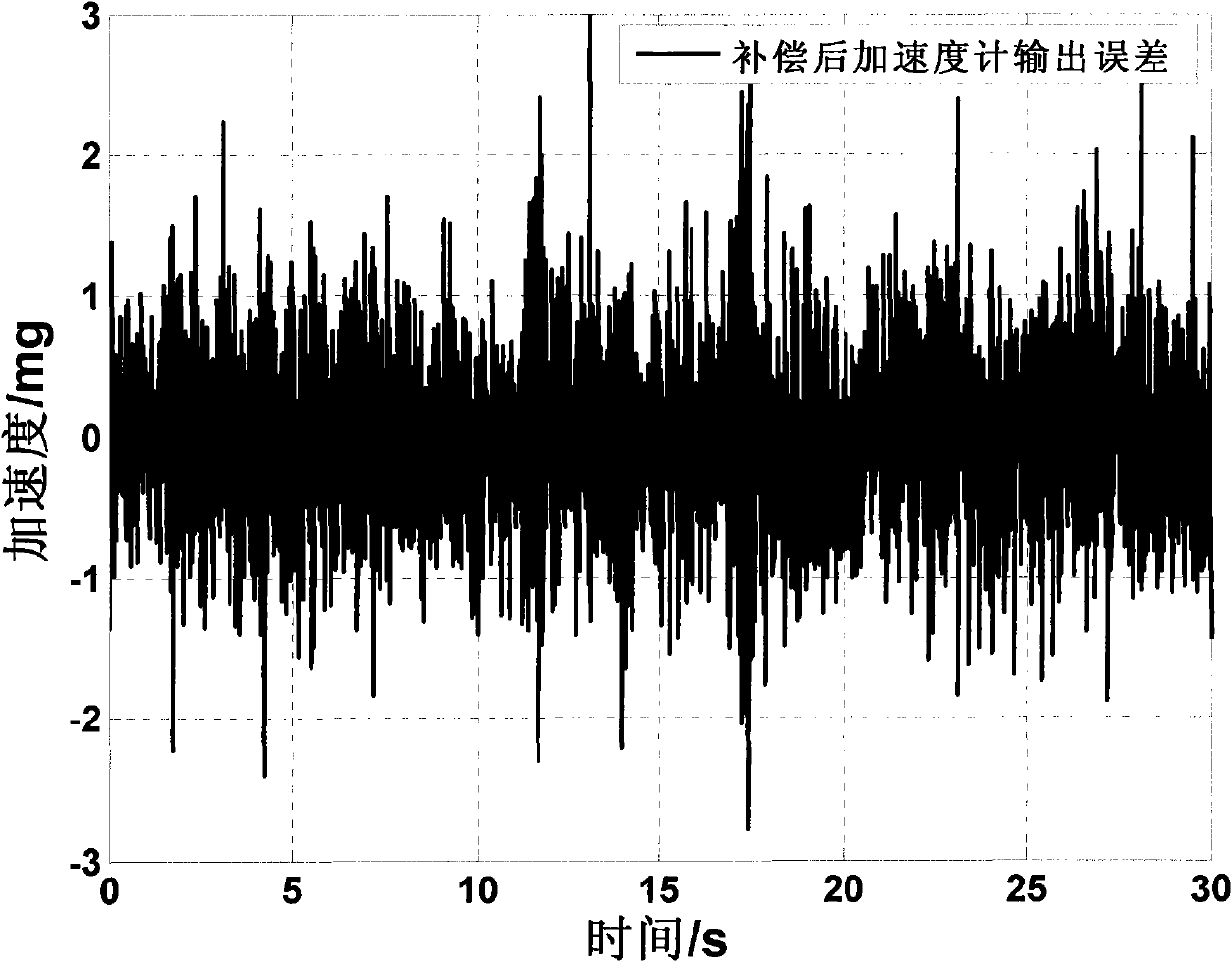

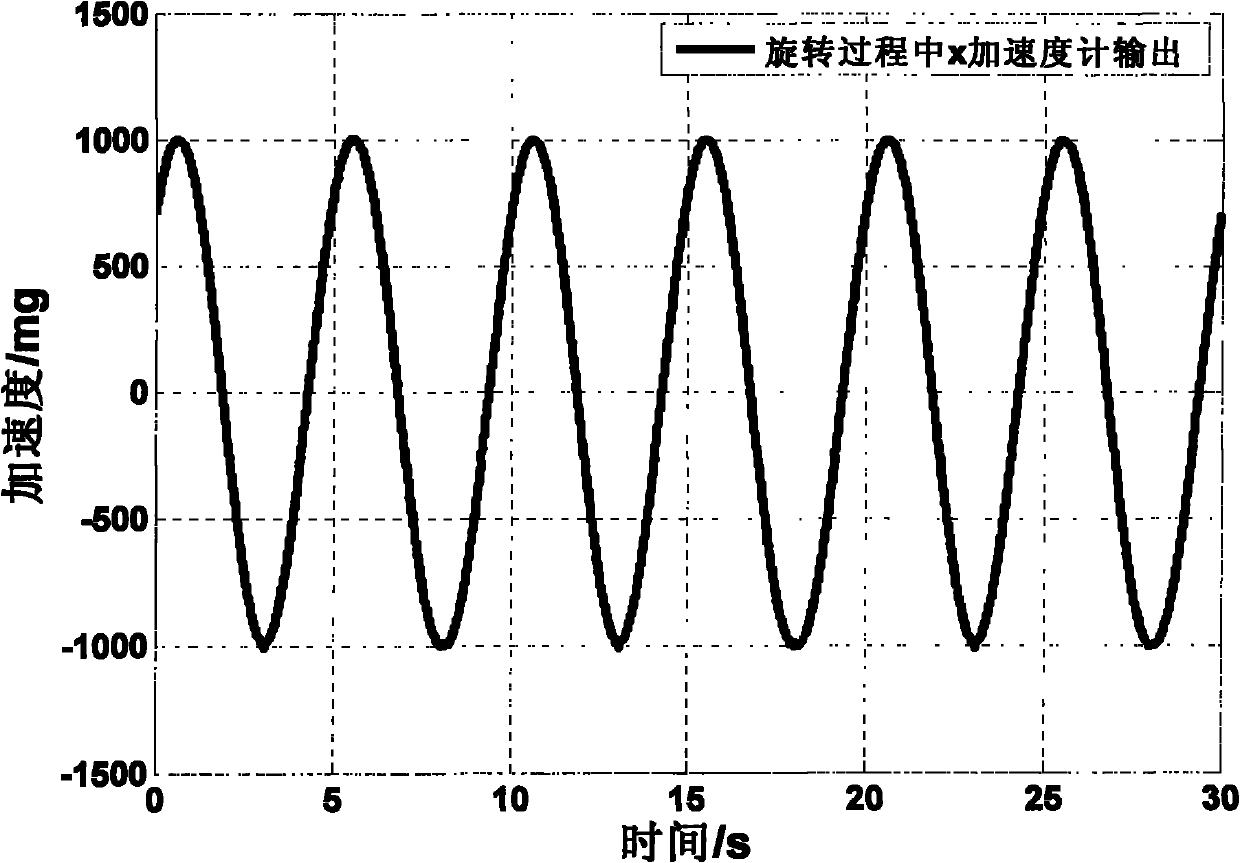

The invention relates to an accelerometer error calibration and compensation method based on a rotary mechanism, which comprises the following steps that: an accelerator is arranged on the rotary mechanism according to a certain requirements; the relationship between the dynamic continuous output of the accelerator and the rotating angle of the rotary mechanism is obtained through the rotation of the rotary mechanism; and a least square method is used for estimating and obtaining the bias, the scale factor, the non-linear error coefficient of the scale factor, the cross-coupling error coefficient and the like of the accelerator. The method uses the rotary mechanism to estimate all error coefficients of the accelerator, and is characterized by accuracy, high efficiency, easy operation, high universality and the like. After the method estimates the error coefficients and carries out corresponding error compensation, the output precision of the accelerator can be greatly improved. The method is also applicable to the calibration of a gyroscope, and can greatly improve the precision in measuring the speed of a top.

Description

technical field The invention relates to an accelerometer error calibration and compensation method, which can be applied to the error calibration and compensation of other inertial devices such as gyroscopes, and belongs to the fields of inertial device testing and inertial navigation. technical background The inertial navigation system has the characteristics of full autonomy, high concealment, high bandwidth, and continuous output. It has strategic significance in national defense and is one of the most important equipment in the fields of aviation, aerospace, and navigation. The performance of inertial devices (gyroscopes and accelerometers) is the most important factor affecting the accuracy of inertial navigation systems. 80% of inertial navigation system errors are caused by device errors. Therefore, improving the accuracy of inertial devices is the most important factor in the development of inertial technology. research content. There are often two ways to improve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01P21/02

Inventor 徐烨烽杨国梁张仲毅李魁

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com