Photoionization gas chromatography detection method of organic volatile compounds in air

An organic volatile matter and gas chromatography technology, which is applied in the field of photoionization gas chromatography detection of organic volatile matter in the air, can solve the problems of increasing sample adsorption, desorption process, longer detection period, and low desorption recovery rate, etc. Achieve the effect of high sensitivity, improved test accuracy and high detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Determination of the concentration of benzene, toluene and xylene in the laboratory.

[0043] The detection system includes: comprehensive syringe container, chromatograph, analyzer.

[0044] Detection steps:

[0045] 1. Sampling: Use a gas sampling syringe to collect 1L (volume under standard conditions) of air on site, and seal the air inlet;

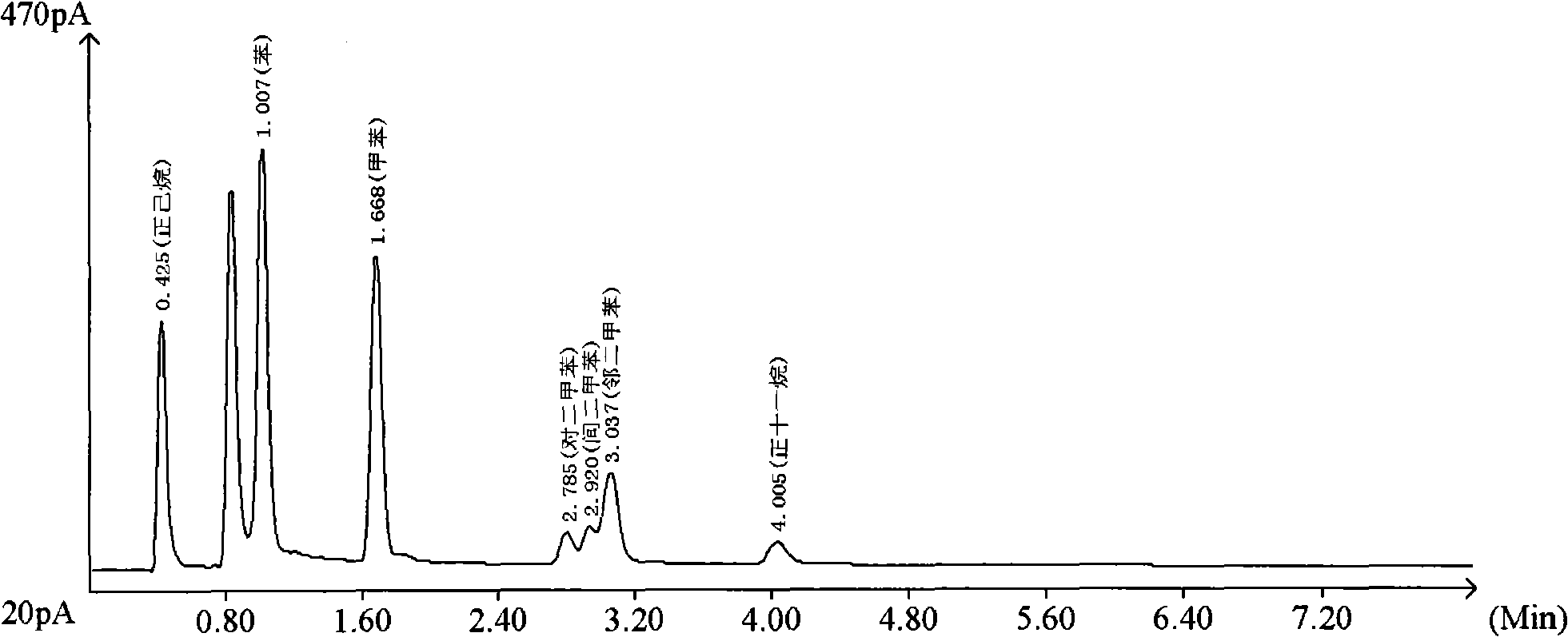

[0046] 2. Determination of the calibration factor: take 0.5 mg of n-hexane, benzene, toluene, and xylene standard liquids and add them to a sampling bag filled with 1L of high-purity nitrogen to prepare a reserve gas. Dilute the reserve gas 1000 times with high-purity nitrogen in another gas distribution syringe, and configure it as an internal standard gas with a concentration of 0.5mg / 1000L of n-hexane, benzene, toluene, and xylene; turn on the power of the chromatograph, and pre- After heating for 30 minutes, adjust the working temperature to 50°C and the pressure to 6pa; adjust the carrier gas flow rate to 15mL / min, direc...

Embodiment 2

[0053] Concentration determination of VOCs in the office.

[0054] The detection system includes: comprehensive syringe container, chromatograph, analyzer.

[0055]Detection steps:

[0056] 1. Sampling: Use a gas sampling syringe to collect 1L (volume under standard conditions) of air on site, and seal the air inlet.

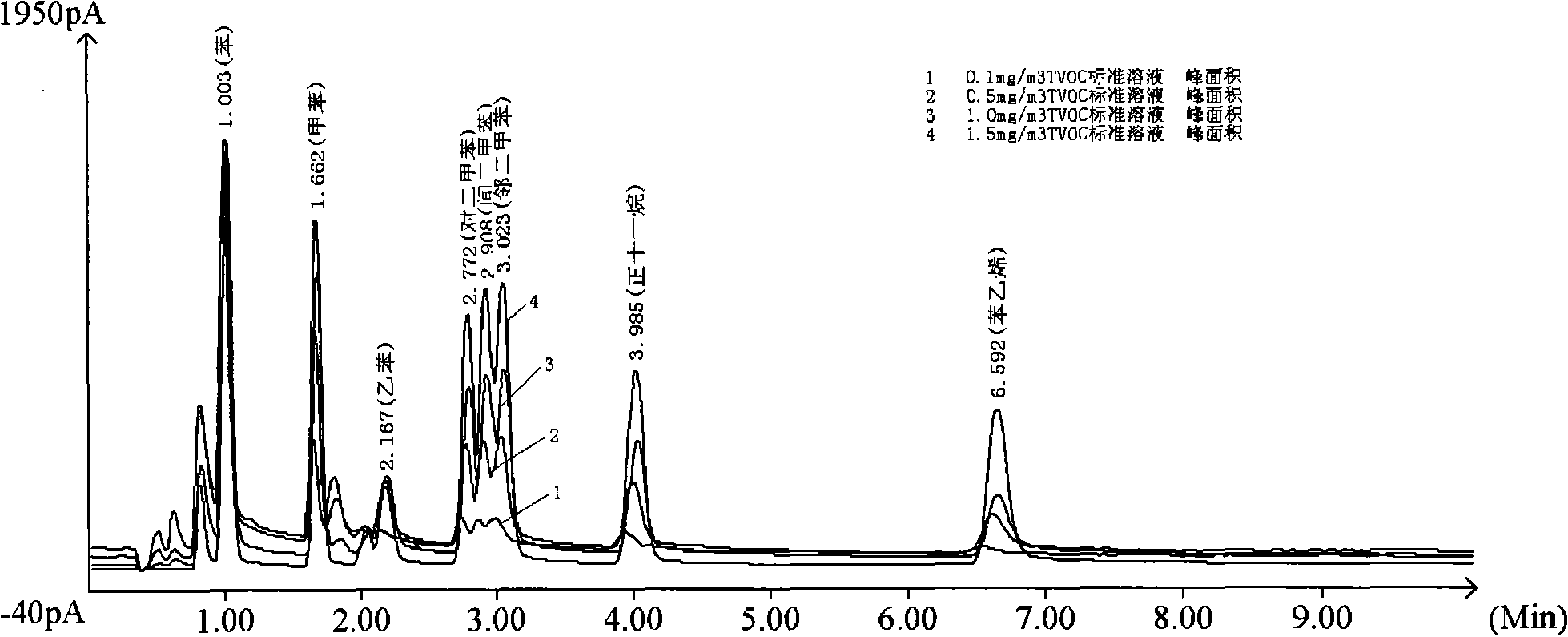

[0057] 2. Draw a standard curve: prepare a VOCs stock solution with a concentration of 1 μL / mL in a 5 mL volumetric flask with methanol as the diluent. Then use a 100mL syringe to dilute and vaporize the stock solution respectively to make the concentration C 1 =0.10mg / m 3 、C 2 =0.20mg / m 3 、C 3 =0.30mg / m 3 、C 4 =0.40mg / m 3 VOCs standard gas. Turn on the power of the chromatograph, preheat for 30 minutes, adjust the working temperature to 50°C, and the pressure to 6pa; adjust the flow rate of the carrier gas to 15mL / min, inject 10.0mL of standard gas directly, and start the instrument. From figure 2 The retention time and peak area of each componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com