Method and device for measuring thickness of numerical control machining workpiece

A technology for thickness measurement and processing of workpieces, applied in metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of low thickness detection efficiency, difficult thickness online detection, etc. The effect of measuring high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

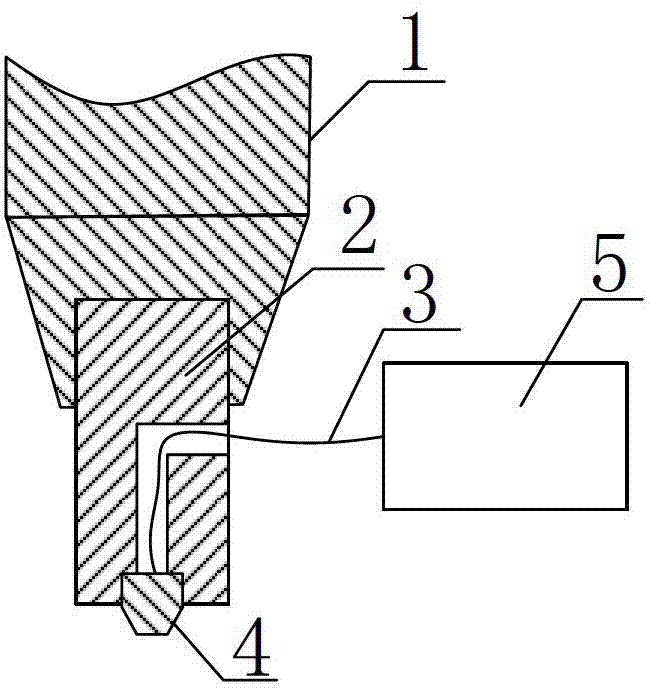

[0027] Such as figure 1 shown.

[0028] A device for measuring the thickness of a numerically controlled workpiece. The thickness measuring device is composed of a handle connection device 2, a data transmission line 3, an ultrasonic probe 4, and a terminal processor 5. The data transmission line 3 realizes data transmission between the ultrasonic probe 4 and the terminal processor 5. One end of the tool handle connecting device 2 is connected with the ultrasonic probe 4 in a threaded connection, and the other end is connected with the tool handle connected to the spindle of the machine tool in a heat-shrinkable connection method (the heat-shrinkable type means that the tool is set before being placed in the tool handle connecting device). Heating the shank, put it into the tool shank connection device after heating, use the principle of thermal expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com