Auxiliary device for steel pipe machining

A technology for auxiliary devices and steel pipes, applied in positioning devices, metal processing, metal processing equipment, etc., can solve the problems of high production cost, low application range, and inability to guarantee a single steel pipe, and achieve the effect of avoiding the inclination of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

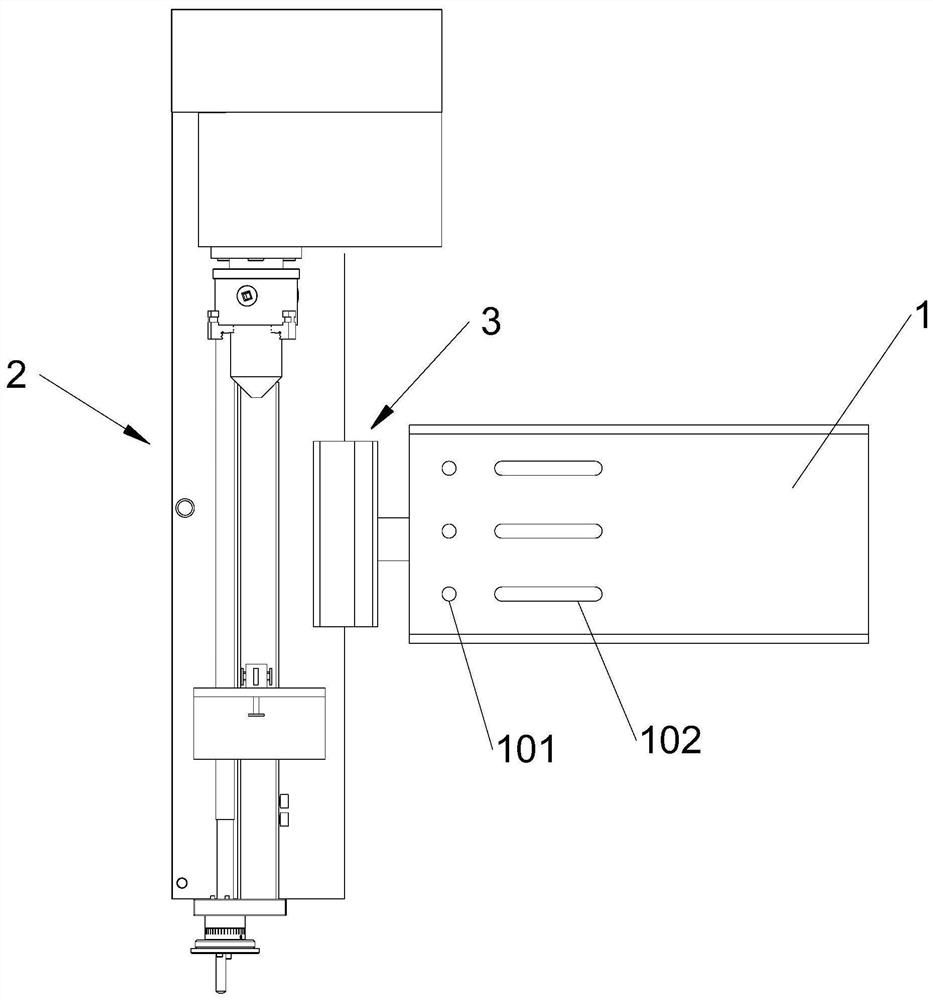

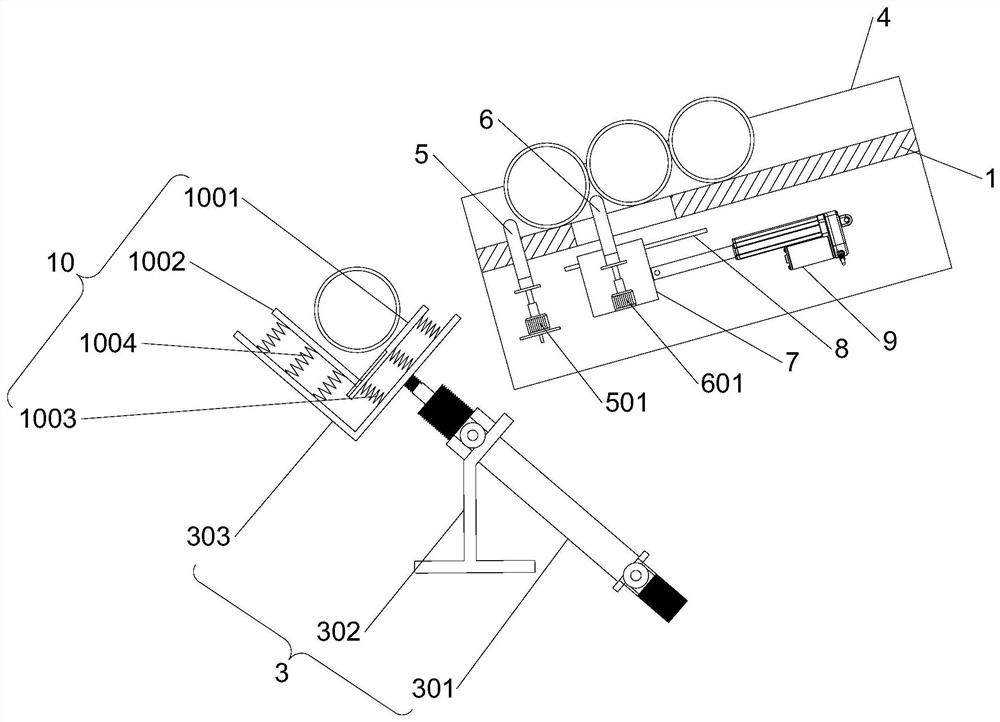

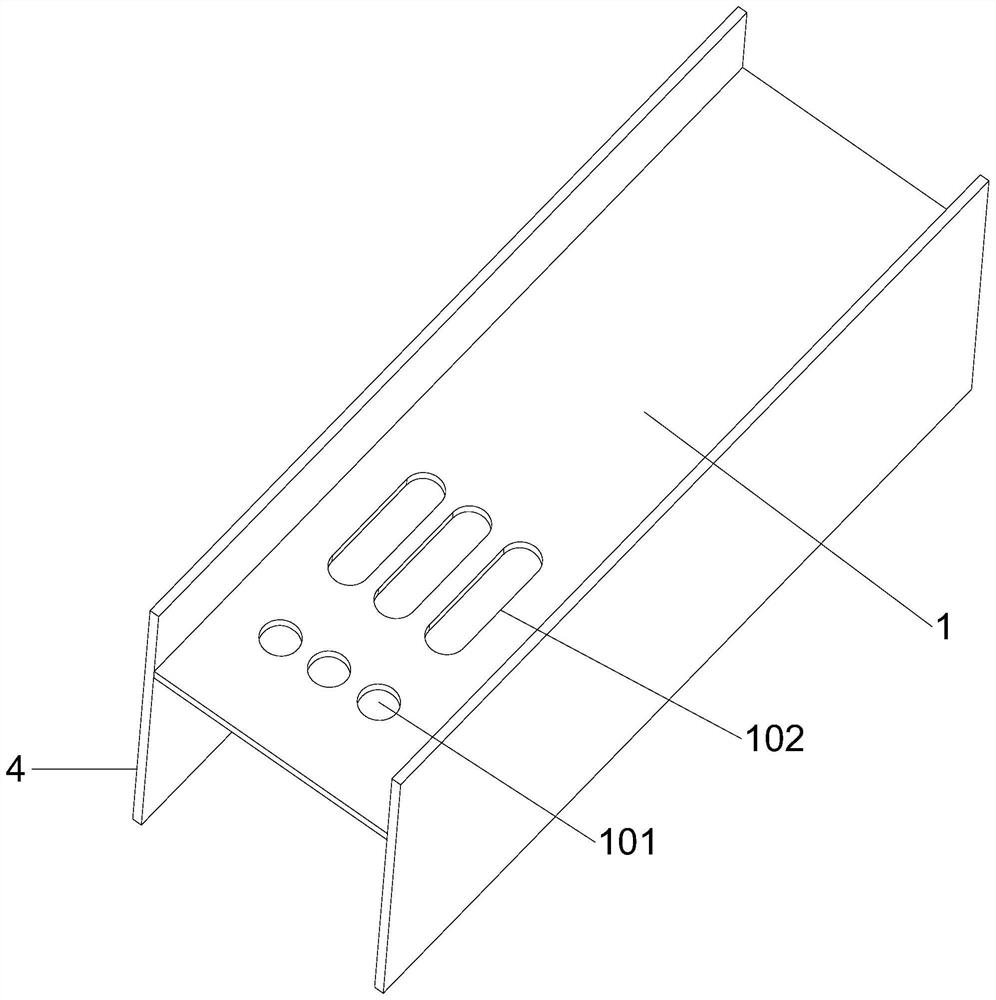

[0033]The auxiliary device for steel pipe processing of the present invention comprises clamping tooling 2 and a conveying plate 1 arranged side by side, the conveying plate 1 is inclined downward along the direction close to the clamping tooling 2, side guard plates 4 are arranged on both sides of the conveying plate 1, The lower end of the conveying plate 1 is provided with a through hole 101, and the first limit rod 5 that can move up and down is provided through the through hole 101. The conveying plate 1 is also provided with a chute 102, and a chute 102 is provided with a The second limit rod 6 for lifting and moving, the lower end of the second limit rod 6 is provided with a fixed box 7, the outer wall of the fixed box 7 is provided with a power assembly 9 for pushing the fixed box 7 to move along the direction of the chute 102, and the clamping tool 2 and the conveying plate 1 are also provided with a transfer assembly 3, the transfer assembly 3 is arranged obliquely an...

Embodiment 2

[0036] This embodiment is further optimized on the basis of Embodiment 1 as follows: a plurality of through holes 101 are arranged side by side, each through hole 101 is provided with a first stop rod 5, and the lower ends of all first stop rods 5 A connecting plate is provided, and a first hydraulic cylinder 501 is provided at the lower end of the connecting plate, and the first hydraulic cylinder 501 is installed on the side wall of the side guard plate 4 . A second hydraulic cylinder 601 is arranged inside the fixed box 7 , and the telescopic shaft of the second hydraulic cylinder 601 is connected to the second limiting rod 6 , and the second limiting rod 6 runs through the outer wall of the upper end of the fixed box 7 . The outer walls on both sides of the fixed box 7 are provided with guide blocks, and the inner walls of the two side guards 4 are provided with guide grooves 8 that are compatible with the guide blocks. The power assembly 9 is an electric push rod installed...

Embodiment 3

[0039] This embodiment is further optimized on the basis of Embodiment 1 as follows: the transfer assembly 3 includes a support plate 303, a third hydraulic cylinder 301 and a fixed frame 302; The plate 303 is connected to the third hydraulic cylinder 301, and the supporting plate 303 is bent downward to form a groove for supporting the steel pipe, and the buffer assembly 10 for buffering the steel pipe is arranged in the groove. The buffer assembly 10 includes a first positioning plate 1001, a second positioning plate 1002, a first buffer spring 1003 and a second buffer spring 1004, the first positioning plate 1001 is inclined downward along the direction that the conveying plate 1 points to the clamping tool 2, and the second The lower ends of the positioning plate 1002 and the first positioning plate 1001 are connected to each other, the planes where the first positioning plate 1001 and the second positioning plate 1002 are located are perpendicular to each other, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com