Material pushing device of waste transfer station

A garbage transfer station and material pushing device technology, which is applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of increasing labor time and labor intensity of workers, high equipment maintenance costs, and affecting timely removal of garbage, etc., to achieve Good pushing effect, reduced labor time and labor intensity, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

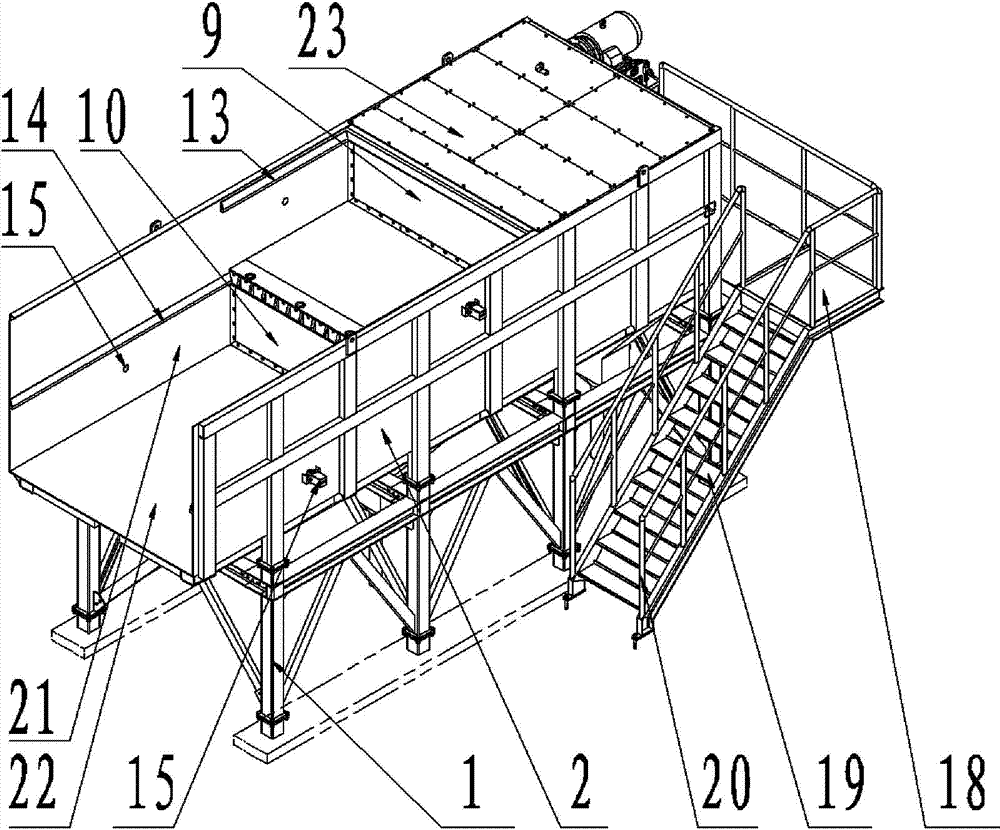

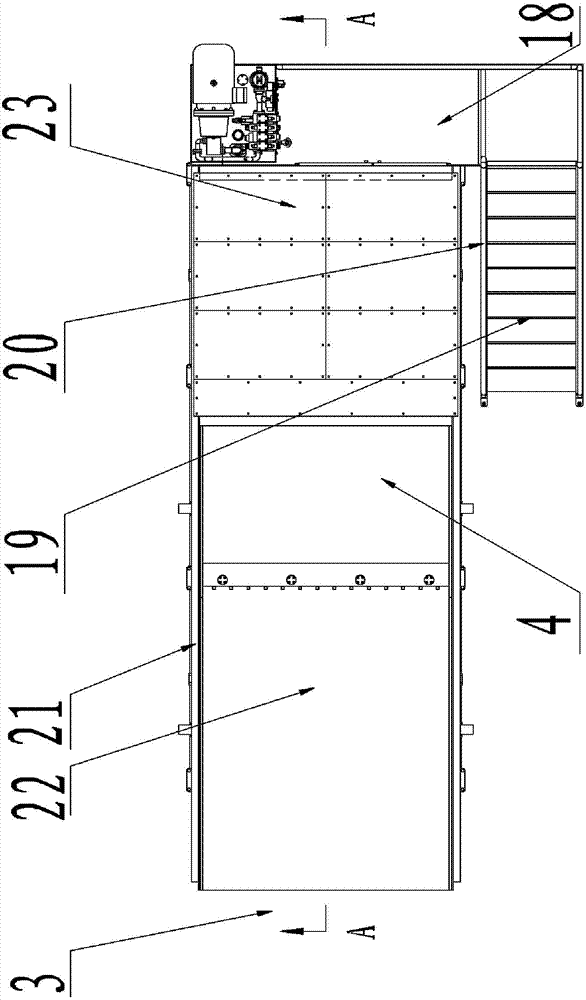

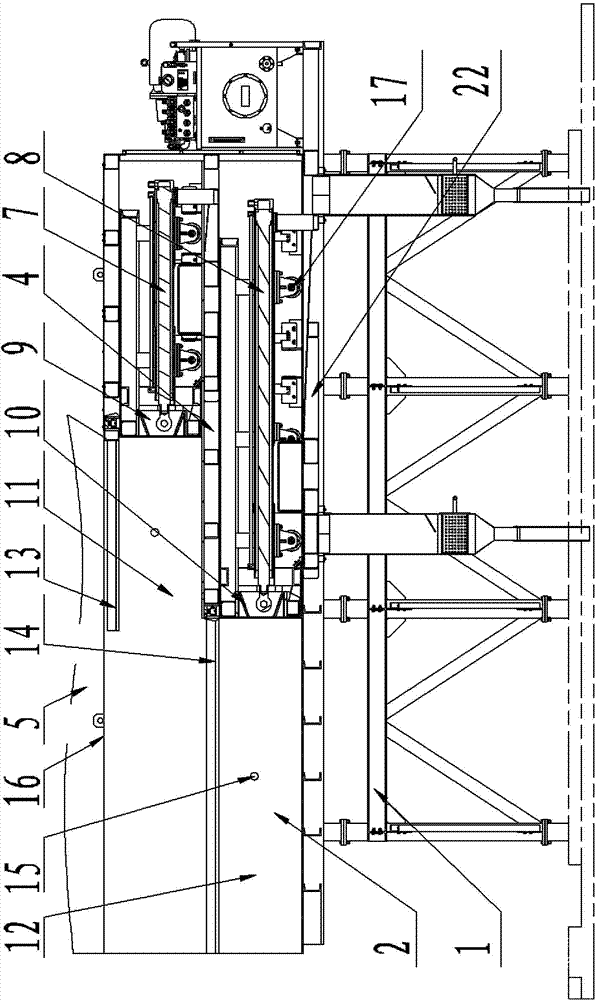

[0031] see Figure 1 ~ Figure 3, is an embodiment of the pushing device of the garbage transfer station, including a frame 1, further, the frame 1 is composed of welded steel, and the structure of the frame can be changed according to the matching garbage compression equipment , can work well with various types of garbage pushing equipment. A working frame 2 is fixed on the top of the frame 1, and the frame and the working frame are fixedly connected by bolts, and the upper end of the working frame 2 is connected with a discharge chute 5. Further, the working frame 2 includes two side plates 21, a bottom plate 22 and a top plate 23, the two side plates 21 are fixed on the left and right sides of the bottom plate 22, the bottom plate is connected with the frame, and the top plate 23 is fixed on the two side plates 21 above. Further, the two side plates 21 and the bottom plate 22 are respectively welded as a whole by section steel and steel plate. Further, an inspection platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com