Blocking method for perforation well sections of slim hole sidetracking well

A perforated well section and drilling technology, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of inconvenient plugging, and achieve the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The above-mentioned technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some, not all, embodiments of the present invention.

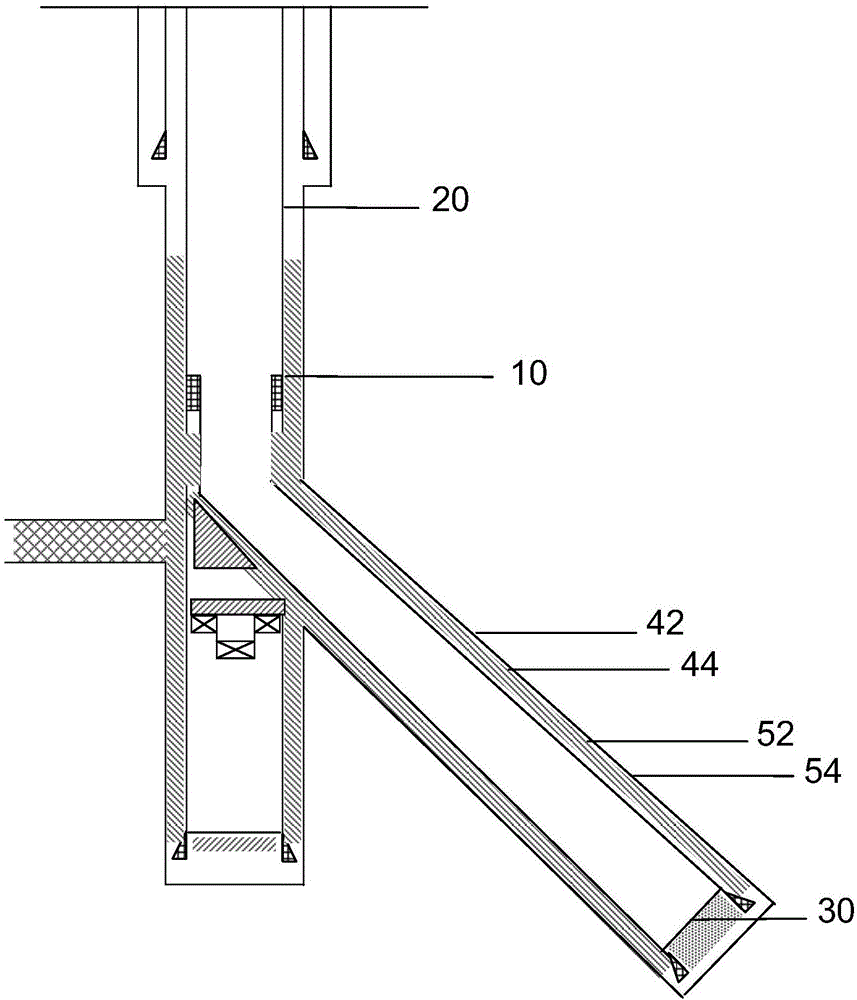

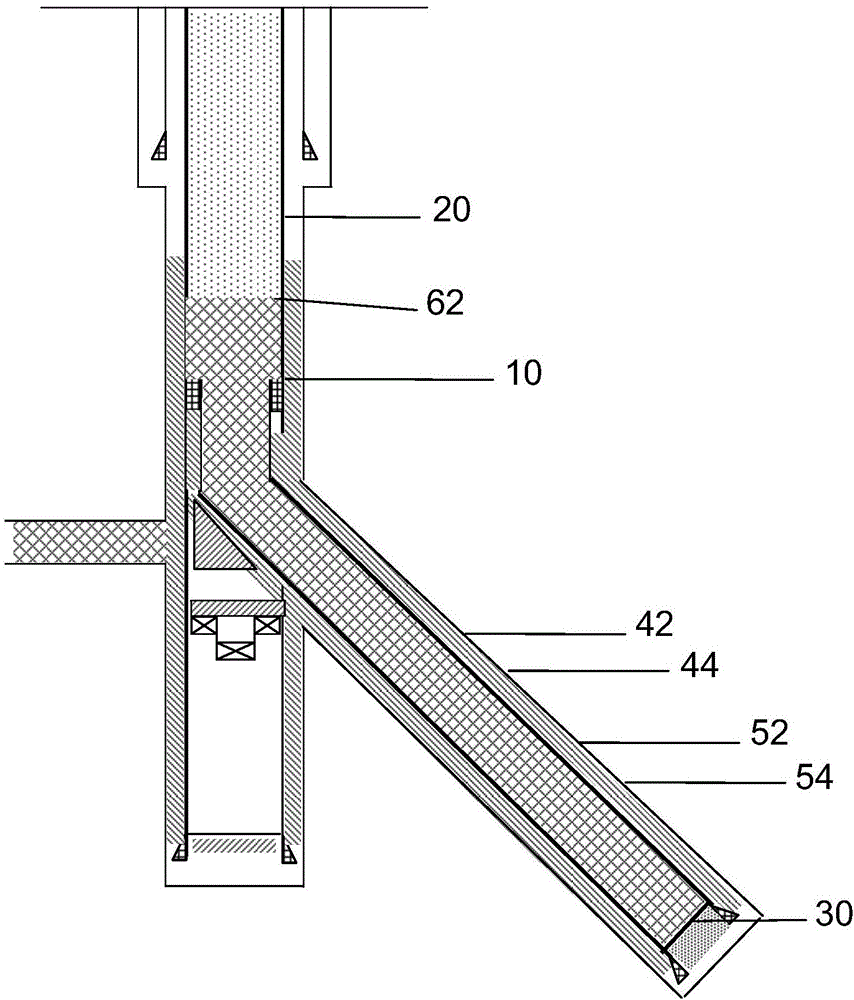

[0047] see figure 1 and figure 2 As shown, there are at least two perforated well sections in the sidetracked well section, and each perforated well section is located at different depths of the sidetracked well section, and the casing 20 at each perforated well section is provided with a hole connected to the formation. holes (not shown). figure 1 and figure 2In the shown embodiment, there are two perforated well sections in the sidetracking well section, and the upper boundary 42 of the first perforated well section and the lower boundary 44 of the first perforated well section are the first perforated well section from top to bottom. For one perforated well section, the second perforated well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com