Special preparation method for improving weather fastness of titanium dioxide

A titanium dioxide, weather resistance technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of difficult to achieve weather resistance, incomplete coating, weather resistance discount, etc., to improve gloss and Dispersibility, reduce photocatalytic effect, improve weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

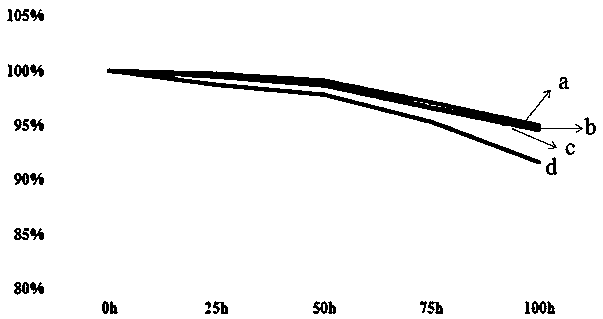

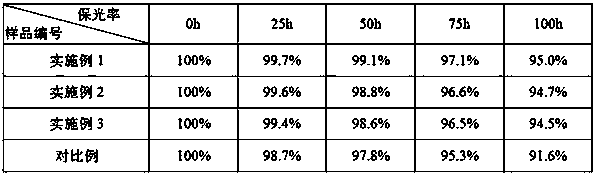

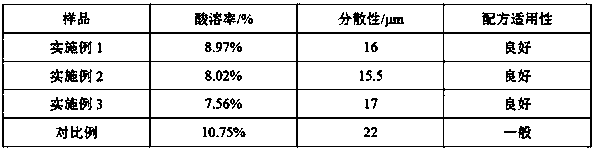

Examples

Embodiment 1

[0034] After the uncoated titanium dioxide is pulverized, wet-milled, sand-milled, and diluted, the slurry concentration is 300g / L, the pH of the slurry is 8.0, the stirring is started, and the temperature is raised to 90°C; 0.1wt% Na is added within 15 minutes 2 SiO 3 solution (as SiO 2 meter), homogenize for 15 minutes; use dilute H 2 SO 4 Adjust the pH value of the slurry to 2.5, homogenize for 20 minutes; add 1wt% FeSO within 60 minutes at the same time 4 Solution and dilute NaOH solution, maintain the pH value of the slurry at 2.5, and homogenize for 30 minutes; adjust the pH value of the slurry with dilute NaOH to 10.2-10.4 within 15 minutes, and homogenize for 20 minutes; add 3.5wt% Na within 20 minutes 2 SiO 3 solution (as SiO 2 total), homogenize for 20min; within 150min-180min, use dilute H 2 SO 4 Adjust the pH of the slurry to 6.5-7.5, homogenize for 30 minutes; use dilute NaOH to adjust the pH of the slurry to 8.0 within 30 minutes, and homogenize for 30 min...

Embodiment 2

[0036] After the uncoated titanium dioxide is pulverized, wet-milled, sand-milled and diluted, the slurry concentration is 250g / L, the pH value of the slurry is 8.0, the stirring is started, and the temperature is raised to 85°C; 0.2wt% Na is added within 15min 2 SiO 3 solution (as SiO 2 meter), homogenize for 15 minutes; use dilute H 2 SO 4 Adjust the pH value of the slurry to 3, homogenize for 20 minutes; add 1.5wt% FeSO within 60 minutes at the same time 4 Solution and dilute NaOH solution, maintain the pH value of the slurry at 3, homogenize for 30 minutes; use dilute NaOH to adjust the pH value of the slurry to 10.2-10.4 within 15 minutes, and homogenize for 20 minutes; add 2.5wt% Na within 20 minutes 2 SiO 3 solution (as SiO 2 total), homogenize for 20min; within 180min-200min, dilute H 2 SO 4 Adjust the pH of the slurry to 6.5-7.5, homogenize for 30 minutes; adjust the pH of the slurry to 8.0 with dilute NaOH within 30 minutes, and homogenize for 30 minutes; add ...

Embodiment 3

[0038] After the uncoated titanium dioxide is pulverized, wet-milled, sand-milled, and diluted, the slurry concentration is 300g / L, the pH value of the slurry is 8.0, the stirring is started, and the temperature is raised to 90°C; 0.25wt% Na is added within 15 minutes 2 SiO 3 solution (as SiO 2 meter), homogenize for 15 minutes; use dilute H 2 SO 4 Adjust the pH value of the slurry to 3.5, homogenize for 20 minutes; add 2.5wt% FeSO within 60 minutes at the same time 4 Solution and dilute NaOH solution, maintain the pH value of the slurry at 3.5, and homogenize for 30 minutes; adjust the pH value of the slurry with dilute NaOH to 10.2-10.4 within 15 minutes, and homogenize for 20 minutes; add 3wt% Na within 20 minutes 2 SiO 3 solution (as SiO 2 total), homogenize for 20min; within 200min-240min, dilute H 2 SO 4 Adjust the pH of the slurry to 6.5-7.5, homogenize for 30 minutes; use dilute NaOH to adjust the pH of the slurry to 8.0 within 30 minutes, and homogenize for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com