Core pulling vacuum valve for die casting and application method thereof

A vacuum valve, core type technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as failure of molten aluminum injection, inability to remove flue gas, and inability to close normally, to eliminate shrinkage cavities Defects, large exhaust cross-sectional area, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

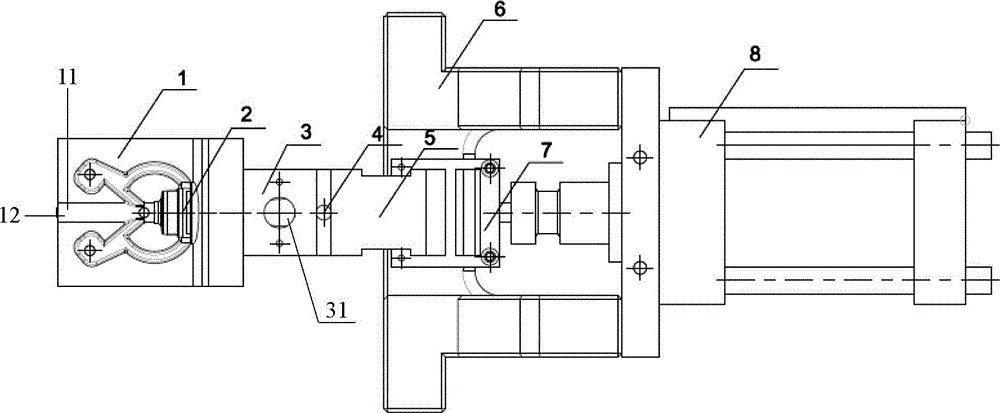

[0025] A core-pulling vacuum valve for die-casting, including a moving module 1, a valve stem 2, a valve head 3, a pressing block 4, a back seat 5, an oil cylinder support 6, a connecting block 7 and an oil cylinder 8, such as figure 1 As shown, the specific structure is:

[0026] The surface of the moving module 1 is a parting surface, and the parting surface is provided with a pipeline 11 for slag collection and exhaust, and the valve stem 2 is arranged in the pipeline 11;

[0027] The central axis of the valve head 3 is provided with a connection hole, and the side wall of the valve head 3 is provided with an air extraction hole 31 connected with the connection hole;

[0028] The valve rod 2 is composed of a front rod and a rear rod connected by a flange. The rear rod of the valve rod 2 is sleeved in the connecting hole of the valve head 3, and the outer wall of the rear rod of the valve rod 2 and the inner wall of the connecting hole of the valve head 3 There is a gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com